High-temperature submersible motor centralizing bearing and centralizing shaft sleeve assembling structure and application thereof

A technology for righting bearings and submersible motors, applied in the direction of electromechanical devices, bearing components, shafts and bearings, can solve the problems of reduced wear resistance, strengthened unilateral magnetic pull, and enhanced rotor vibration, and achieve excellent use effects. The effect of excellent wear resistance and excellent service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

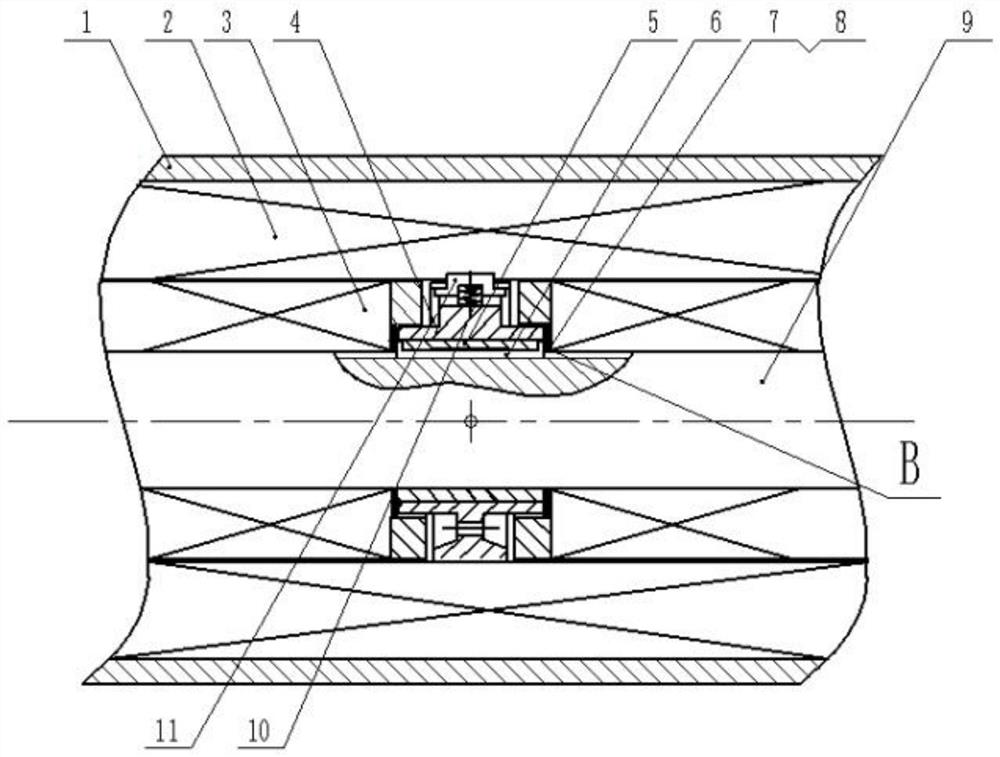

Embodiment 1

[0020] This embodiment provides an assembly structure of a centralizing bearing and a centralizing shaft sleeve, the assembly structure is installed in a high-temperature submersible motor, wherein the assembly section between the outer circle of the centralizing bearing and the stator core of the high-temperature submersible motor is provided with a silicon steel sheet; The bearing is made of non-magnetic austenitic stainless steel; the centralizing shaft sleeve is made of aluminum bronze QAL9-4-4-2 or QAL10-4-4; The gap between the outer circle of the bearing and the inner hole of the motor stator is 0.02-0.05mm at the working temperature; the gap between the inner hole of the centralizing shaft sleeve and the motor shaft is 0.01-0.03 at the working temperature. The surface of the inner hole of the centralizing bearing is provided with a wear-resistant layer, that is, a wear-resistant layer prepared by nitriding; the thickness of the wear-resistant layer is DN=0.15-0.25 mm, a...

Embodiment 2

[0022] This embodiment provides the manufacturing and assembling method of the centralizing bearing and centralizing bushing assembly structure of the first embodiment. Take the centering bearing and centering bushing of the GYQY143-100D high temperature submersible motor as an example for detailed description. It is known that the operating temperature of the high-temperature submersible motor is 280°C, and it is required that at this operating temperature, the working gap between the friction pair of the centralizing bearing and the centralizing bushing is 0.06-0.08mm; the gap between the inner hole of the centralizing bushing and the motor shaft is 0.01 ~0.03mm.

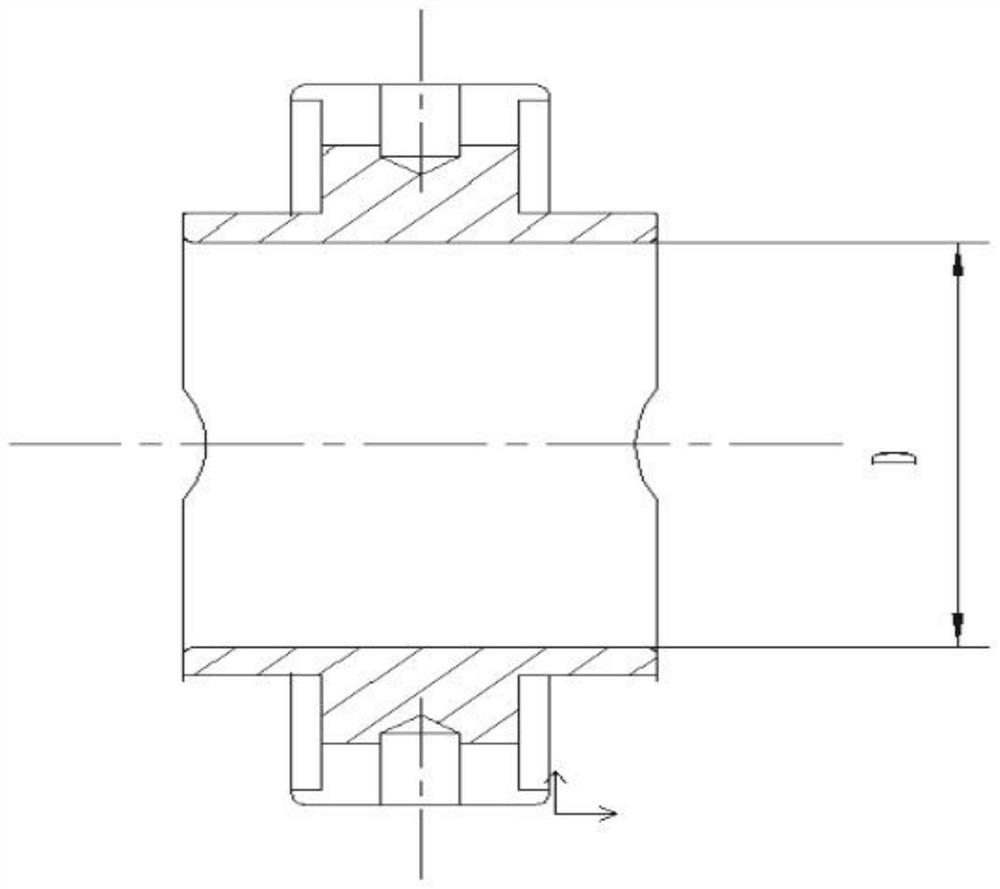

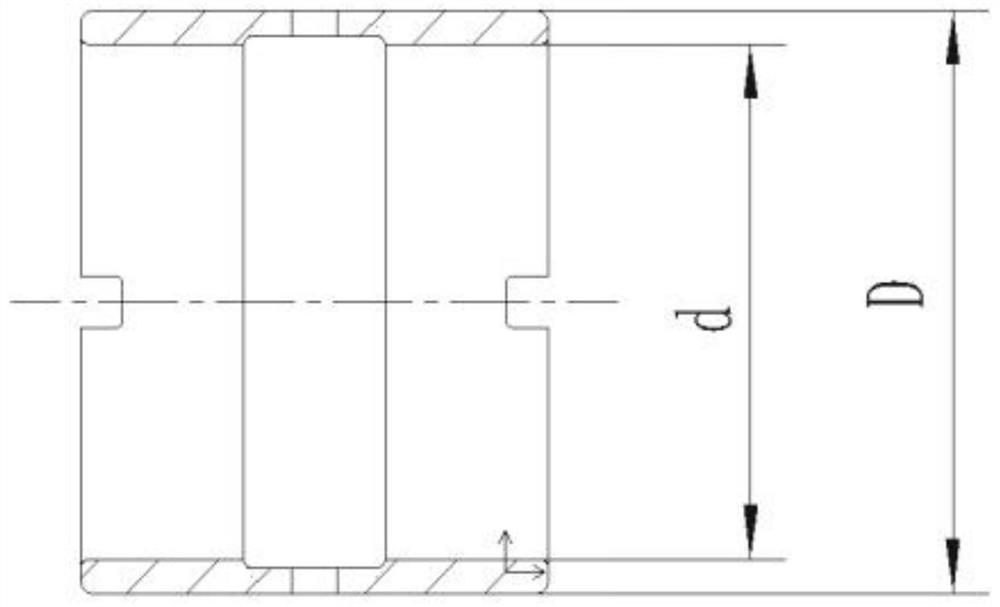

[0023] Find the dimensions of the outer diameter and inner hole of the centralizing bushing after processing at room temperature. See figure 2 , image 3 .

[0024] 1. Find the processing size of the outer diameter of the centralizing bushing at room temperature:

[0025] Fuzheng bearing material adopts 316 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com