Liquid organic zinc battery and application thereof

An organic zinc and battery technology, applied in the manufacture of batteries, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problems of strict manufacturing environment and complex production process, and achieve a wide range of applications, high electrochemical properties, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Zinc negative electrode: a zinc disc with a diameter of 1.5cm

[0048] Zinc salt: zinc chloride

[0049]Lower organic solvent: ethylene glycol

[0050] Positive active material: Tetramethylpiperidine nitrogen oxide

[0051] Upper organic solvent: cyclohexane

[0052] Positive current collector: conductive sponge

[0053] The layering situation of the ethylene glycol that is dissolved with zinc chloride and the hexanaphthene that is dissolved with tetramethylpiperidine nitrogen oxide in embodiment 1 is as follows figure 2 shown.

[0054] The CV curve of the battery constructed in Example 1 is as follows image 3 As shown, the charge and discharge curve of the first cycle is as follows Figure 4 shown by image 3 and Figure 4 It can be seen that the battery can be charged at an external voltage of 2.1V, the discharge platform voltage is 1.5V, and the capacity is 8.1mAh.

Embodiment 2

[0056] Zinc negative electrode: a zinc disc with a diameter of 1.5cm

[0057] Zinc salt: zinc chloride

[0058] Lower organic solvent: ethylene glycol

[0059] Positive active material: ferrocene

[0060] Upper organic solvent: cyclohexane

[0061] Positive current collector: conductive sponge

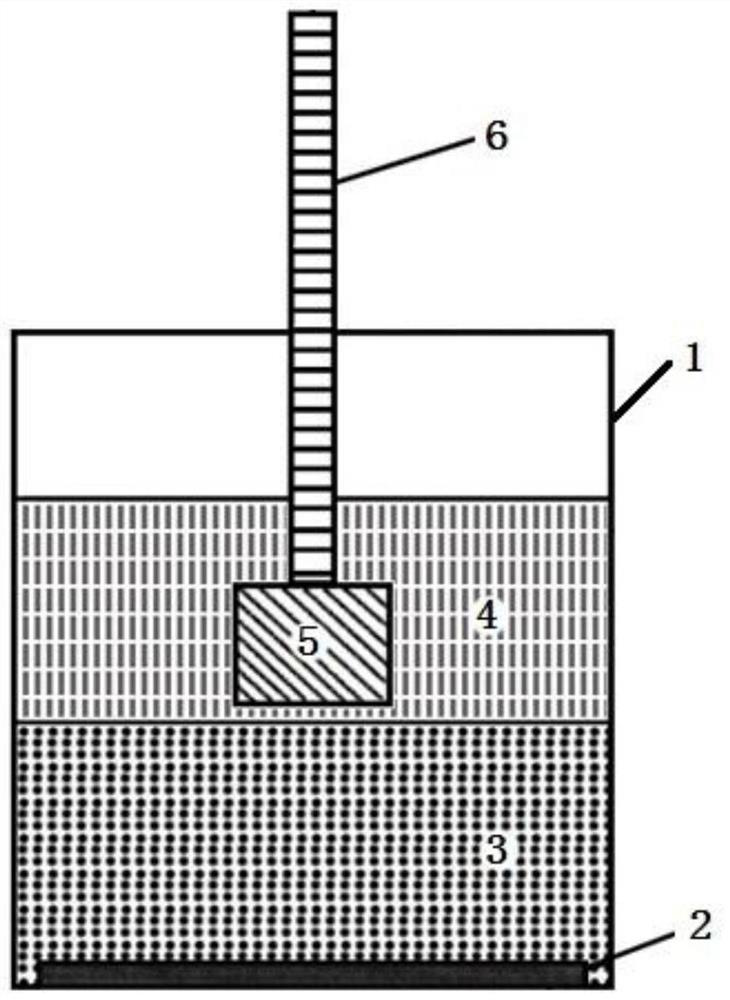

[0062] The layering situation of the ethylene glycol that is dissolved with zinc chloride and the cyclohexane that is dissolved with ferrocene in embodiment 2 is as follows Figure 5 shown.

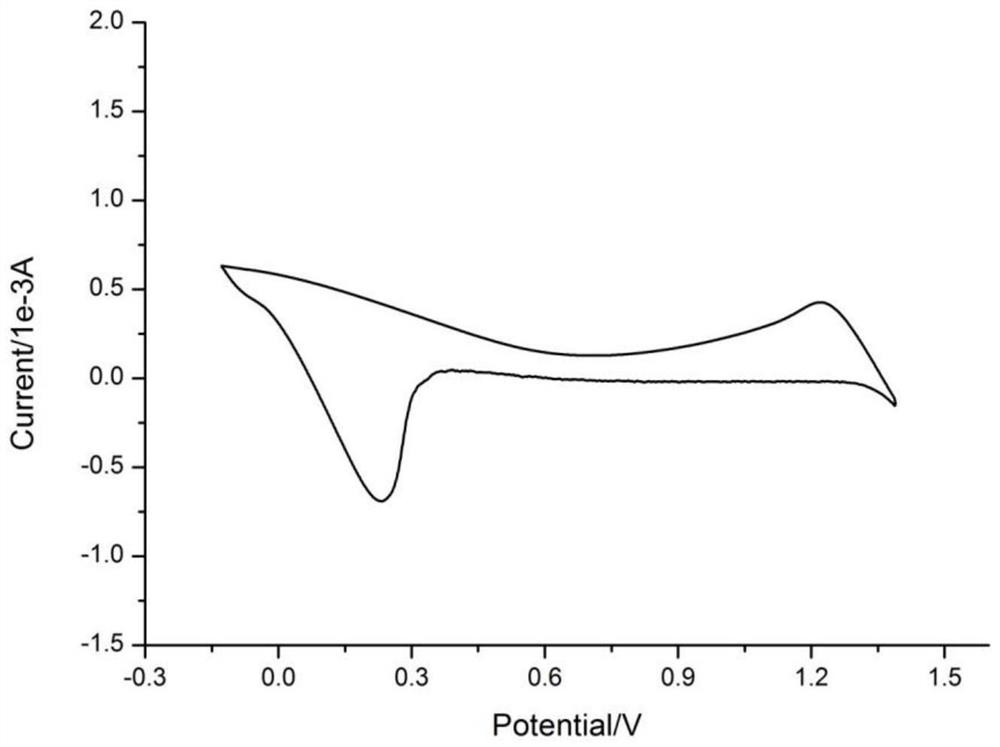

[0063] The CV curve of the battery constructed in embodiment 2 is as follows Figure 6 As shown, the charge and discharge curve of the first cycle is as follows Figure 7 shown by Figure 6 and Figure 7 It can be seen that the battery can be charged at an external voltage of 2.0V, the discharge platform voltage is 0.5V, and the capacity is 8.9mAh.

Embodiment 3

[0065] Zinc negative electrode: a zinc disc with a diameter of 1.5cm

[0066] Zinc salt: zinc chloride

[0067] Lower organic solvent: ethylene glycol

[0068] Positive active material: ferrocene

[0069] Upper organic solvent: petroleum ether

[0070] Positive current collector: conductive sponge

[0071] The layering situation of the ethylene glycol that is dissolved with zinc chloride and the sherwood oil that is dissolved with ferrocene in embodiment 3 is as follows Figure 8 shown.

[0072] The battery constructed in Example 3 can be charged at an external voltage of 2.0V, the discharge platform voltage is 0.5V, and the capacity is 8.4mAh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com