A bearing oiling device

An oil injection device and bearing technology, which is applied in the direction of shafts and bearings, bearing components, lubricating parts, etc., can solve the problems of uneven application of lubricating oil on the bearing surface, avoid cleaning difficulties, avoid lubricating oil waste, and evenly lubricate the bearing surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

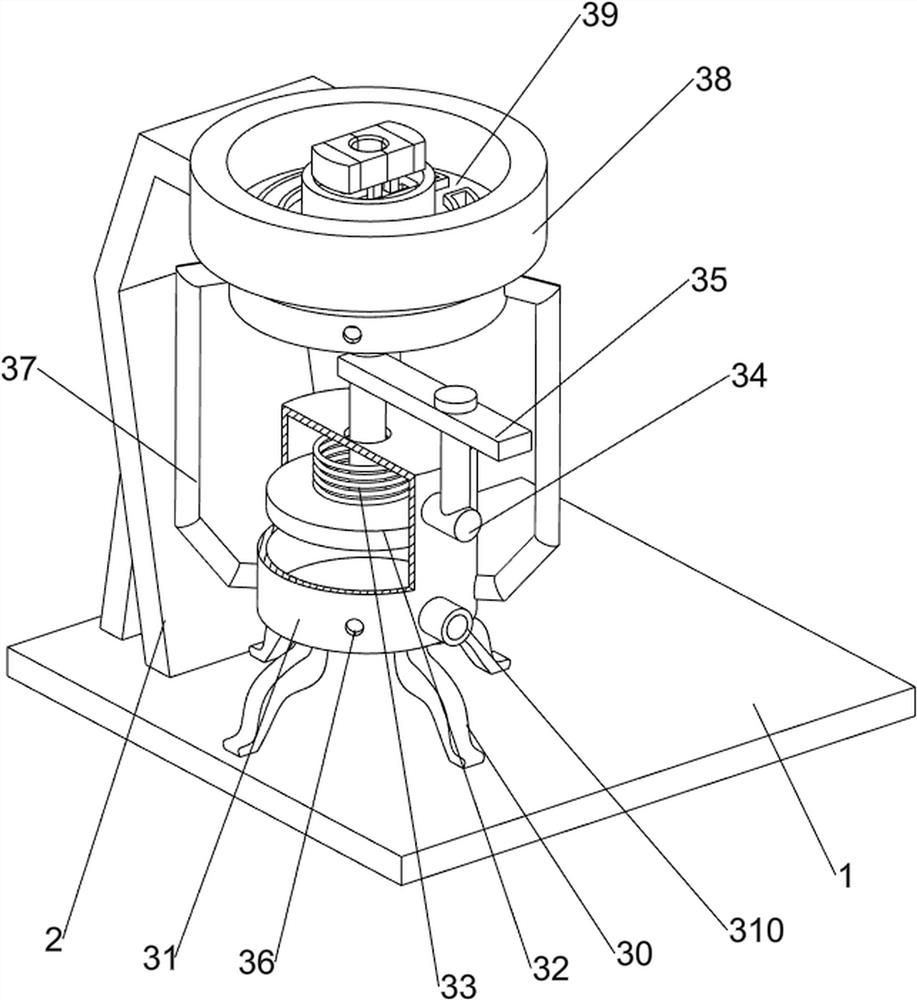

[0022] A bearing oiling device, such as figure 1 As shown, it includes a bottom plate 1, a bracket 2, an oiling assembly 3 and a clamping assembly 4. A bracket 2 is provided on the rear side of the top of the bottom plate 1. An oiling assembly 3 is installed in the middle of the top of the bottom plate 1. The oiling assembly 3 is connected to the bracket 2. The bottom plate 1 A clamping assembly 4 is installed on the front side of the top, and the clamping assembly 4 is connected with the oil injection assembly 3 .

[0023] When people need to fill the bearing with oil, people first pour the lubricating oil into the parts of the oil injection assembly 3, then place the bearing on the parts of the oil injection assembly 3, and then press down the parts of the clamping assembly 4 by hand to clamp The parts of the clamping assembly 4 move downward to press the bearing on the parts of the oil injection assembly 3, and at the same time, the parts of the clamping assembly 4 move dow...

Embodiment 2

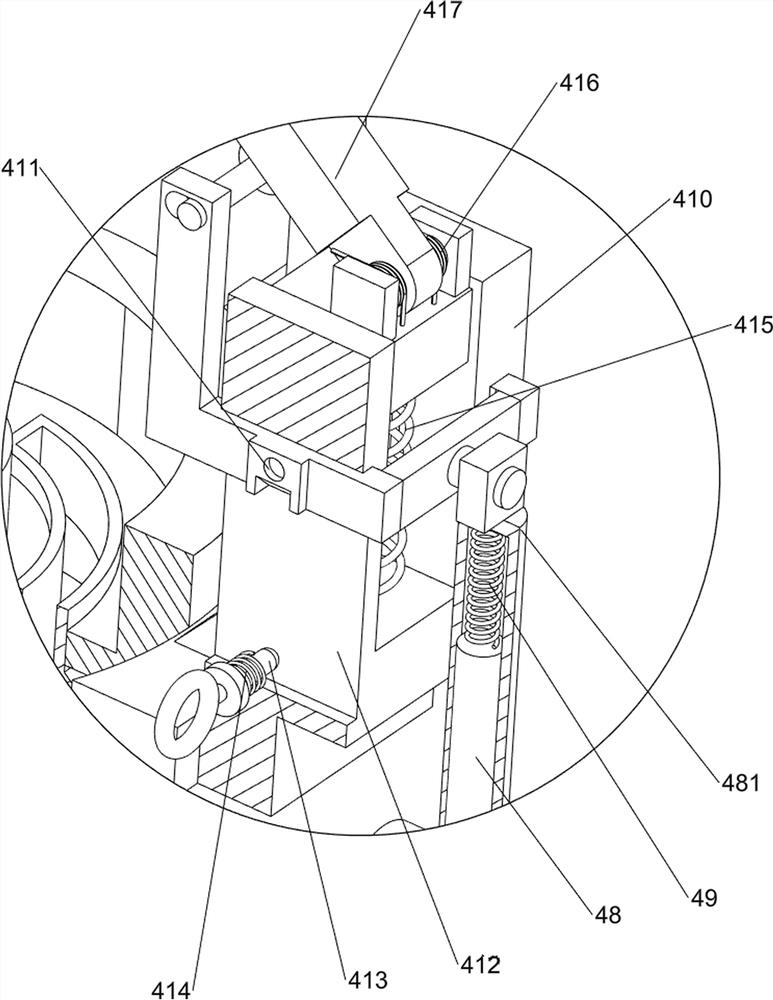

[0025] On the basis of Example 1, such as Figure 2-4 As shown, the oil injection assembly 3 includes a base 30, a piston cylinder 31, a piston rod 32, a first spring 33, a guide rod 34, a pressure plate 35, an oil outlet pipe 37, a placement sleeve 38, an oil outlet sleeve 39 and a one-way valve 310, and a bottom plate 1 The base 30 is evenly arranged on the left side of the top, the number of the bases 30 is 4, the piston cylinder 31 is connected between the tops of the bases 30, the top of the piston cylinder 31 is slidingly connected to the piston rod 32, the bottom of the piston rod 32 and the top of the inner wall of the piston cylinder 31 A first spring 33 is connected between them, a guide rod 34 is connected to the upper side of the front part of the piston cylinder 31, and a pressure plate 35 is slidingly connected to the guide rod 34. Oil outlet hole 36, the quantity of oil outlet hole 36 is 4, oil outlet pipe 37 is connected in the middle part of oil outlet hole 36...

Embodiment 3

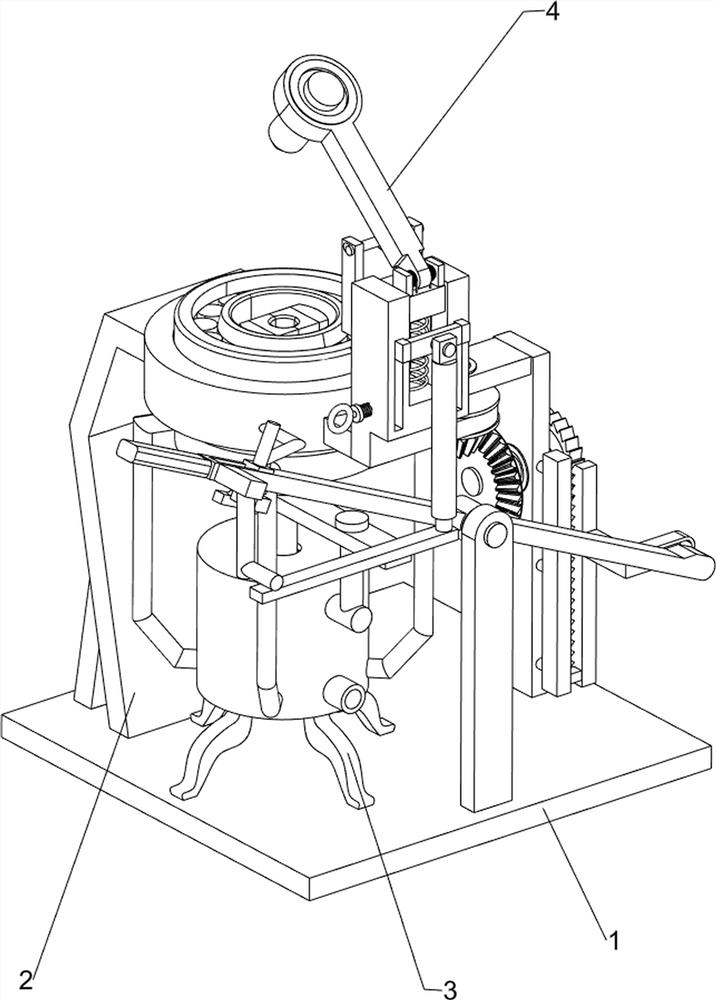

[0030] On the basis of Example 2, such as Figure 5 Shown, also includes rotating assembly 5, and rotating assembly 5 includes slide block 50, ratchet rack 51, mount 52, ratchet gear 53, guide block 54, full gear 55, second rotating shaft 56, bevel gear 57 and belt pulley Group 58, base plate 1 top right side is provided with mounting seat 52, and mounting seat 52 front lower side is connected with guide block 54, and guide block 54 right part is slidably connected with spine rack 51, and spine rack 51 front upper side is provided with Sliding block 50, sliding block 50 is connected with the sliding type of the right side rear part of warping rod 46, and the right part of the upper side of the mounting base 52 is connected with the spine gear 53 in a rotational manner, and the spine gear 53 is meshed with the spine rack 51, and the spine gear 53 left Full gear 55 is provided, and the left side of mounting base 52 is connected with the second rotating shaft 56 in a rotational m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com