A machining method of pdc drill bit based on machine tool programming

A processing method and drill bit technology, which is applied to drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of time and energy consumption, and achieve the effects of improving processing efficiency, shortening programming time, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the examples, which are explanations of the present invention rather than limitations.

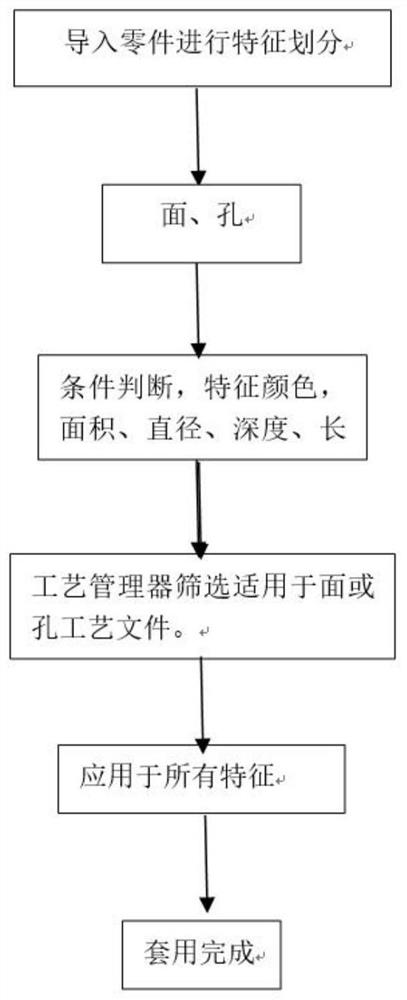

[0029] A kind of PDC drill processing method based on machine tool programming, comprises the following operations:

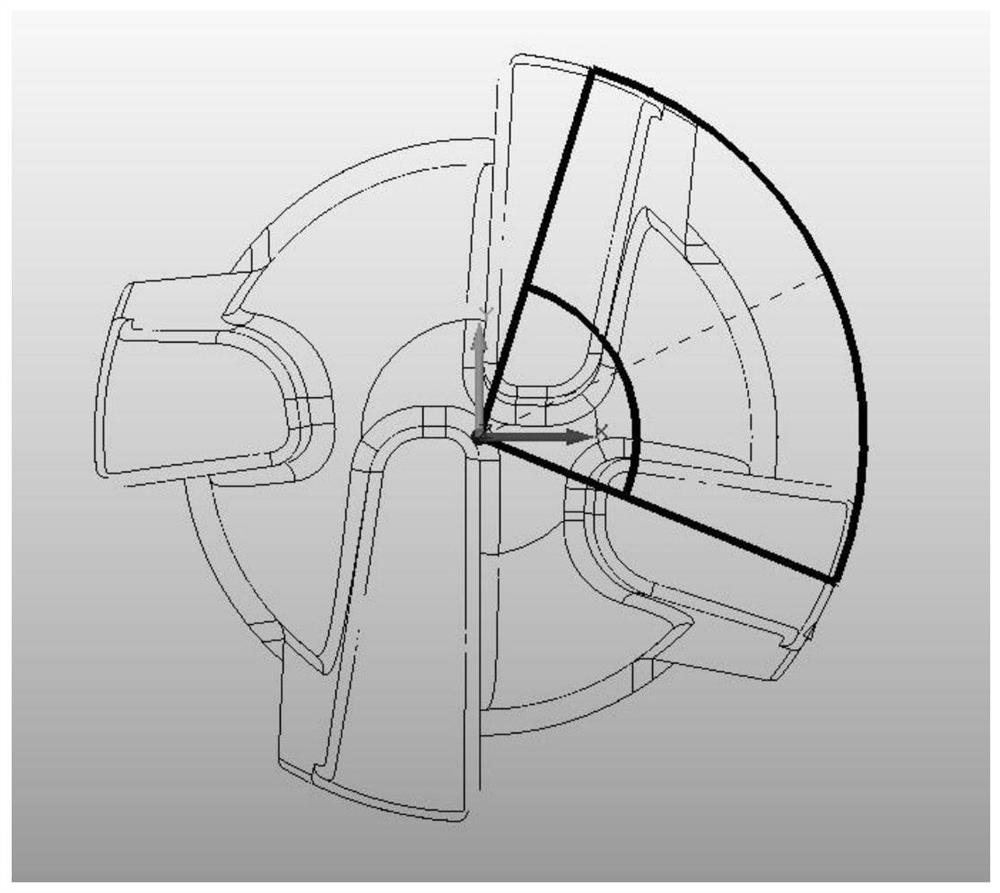

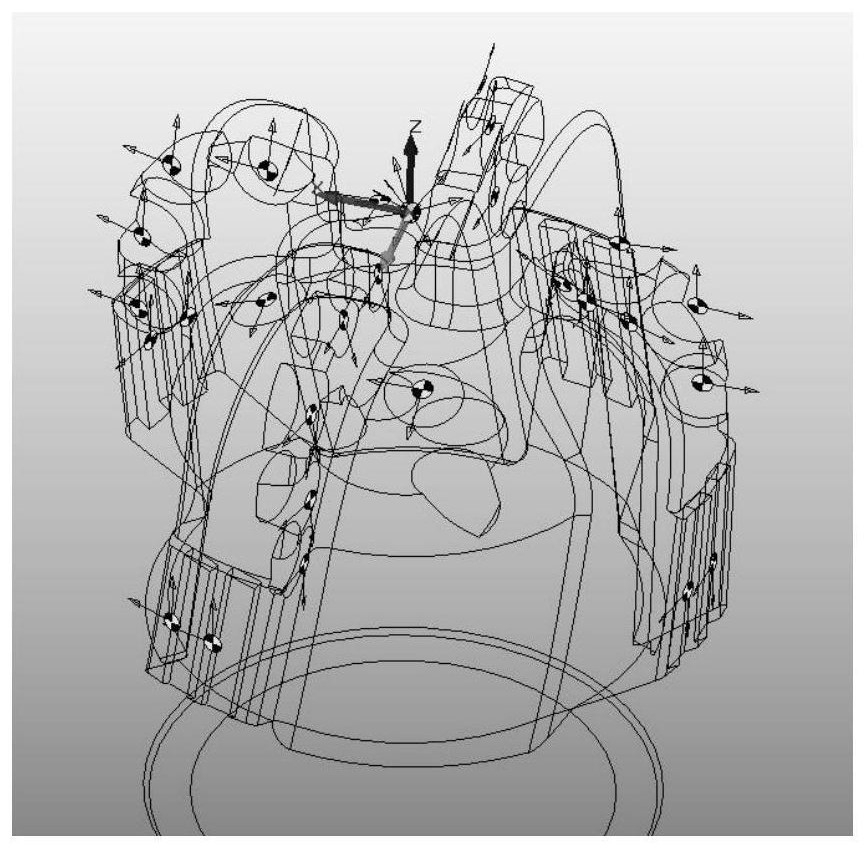

[0030] 1) The flow channels of the PDC drill bit are respectively established as EspritCAM free-form surface features (that is, the outer surface of the drill bit), and these established free-form surface features will be used for rough and fine milling. Use the macro function of EspritCAM software to record the operation process of selecting free-form surface features into a macro, and package it into a DLL file to make an external plug-in and load it into the software with icon commands. In order to identify more accurately, the VB code that is recorded as a macro and opened in the EspritCAM macro function can be used to generate a new macro suitable for the quick selection of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com