Prefabricated pier connecting system of fabricated beam bridge and construction method thereof

A technology of connection system and construction method, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., and can solve problems such as high construction accuracy and grouting quality requirements, accurate positioning and grouting stringent requirements, and increasing the cost of manufacturing pier columns , to achieve the effect of reducing wet grouting work, increasing construction speed, and simplifying construction work procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

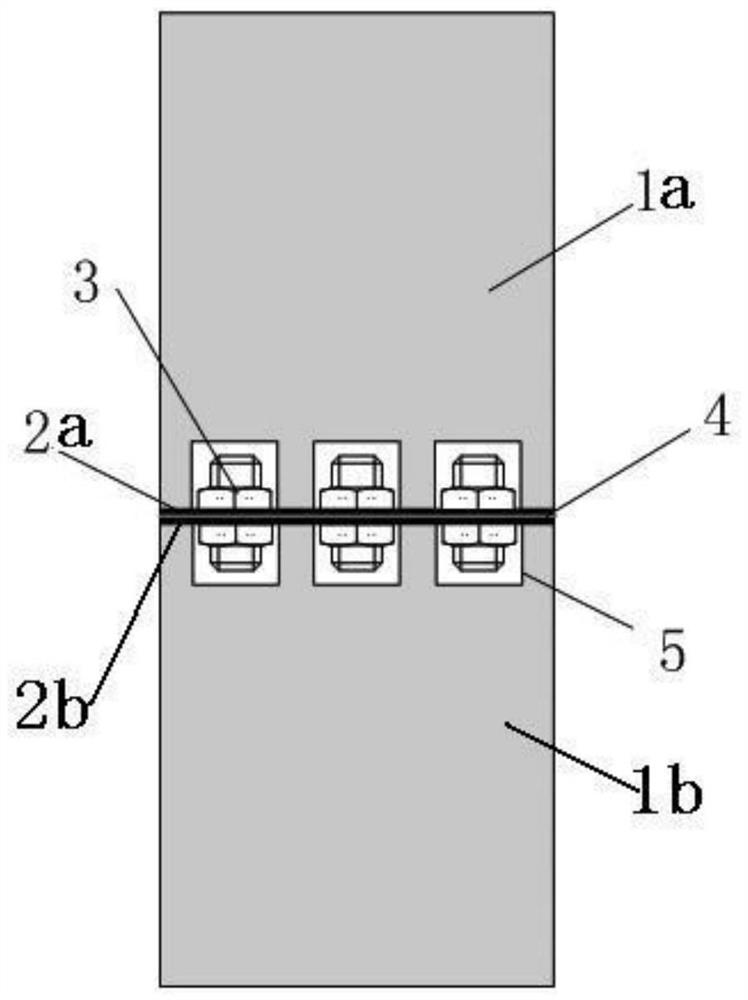

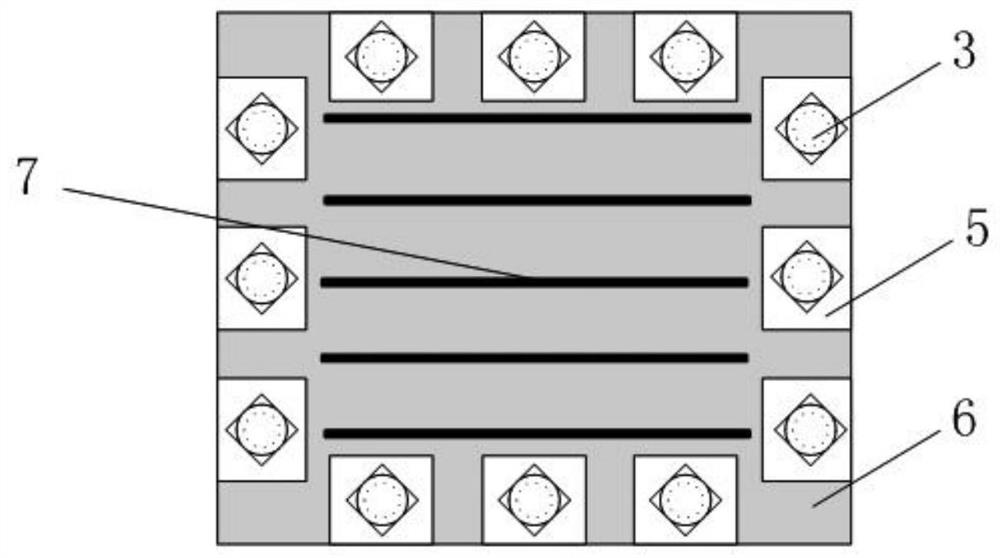

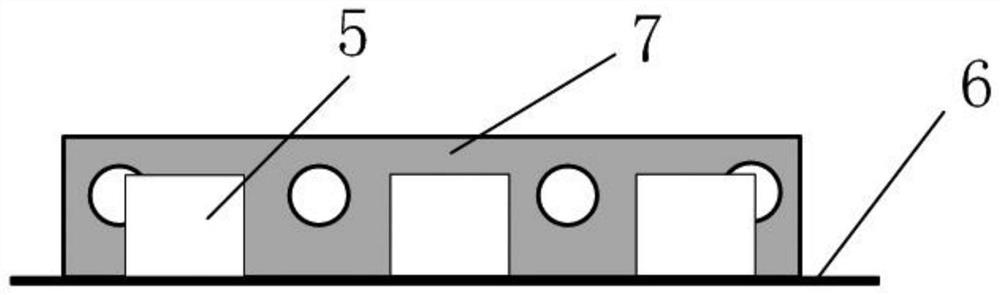

[0027] This example firstly introduces a prefabricated pier connection system for a prefabricated girder bridge, including several prefabricated piers (such as figure 1 Shown are two prefabricated piers: prefabricated pier 1a, prefabricated pier 2 1b) and steel members arranged between adjacent prefabricated piers, the steel members are arranged in pairs (such as figure 1 Steel member 1 2a and steel member 2 2b shown), each steel member includes fastener 3, end plate 6 and connecting plate 7, one side of end plate 6 is equipped with connecting plate 7 and fastener 3, and the other side is laid The epoxy resin layer 4 ; the connecting plate 7 and the fasteners 3 are embedded in the prefabricated pier, and the epoxy resin layer 4 is located between a pair of end plates 6 .

[0028] The present application realizes the connection of adjacent prefabricated piers with fasteners 3 and connecting plates 7 , and buffers with epoxy resin layer 4 between end plates 6 . Compared with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com