Prefabricated pier and bent cap connecting system of fabricated beam bridge and construction method thereof

A connection system and prefabricated technology, applied in the construction parts of railways or bridges, and roads, can solve the problems of high construction precision and grouting quality requirements, increasing the cost of manufacturing piers and cover beams, and difficulty in detecting the density of sleeve grouting. Achieve the effect of reducing wet grouting work, construction speed and convenience, and easy quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

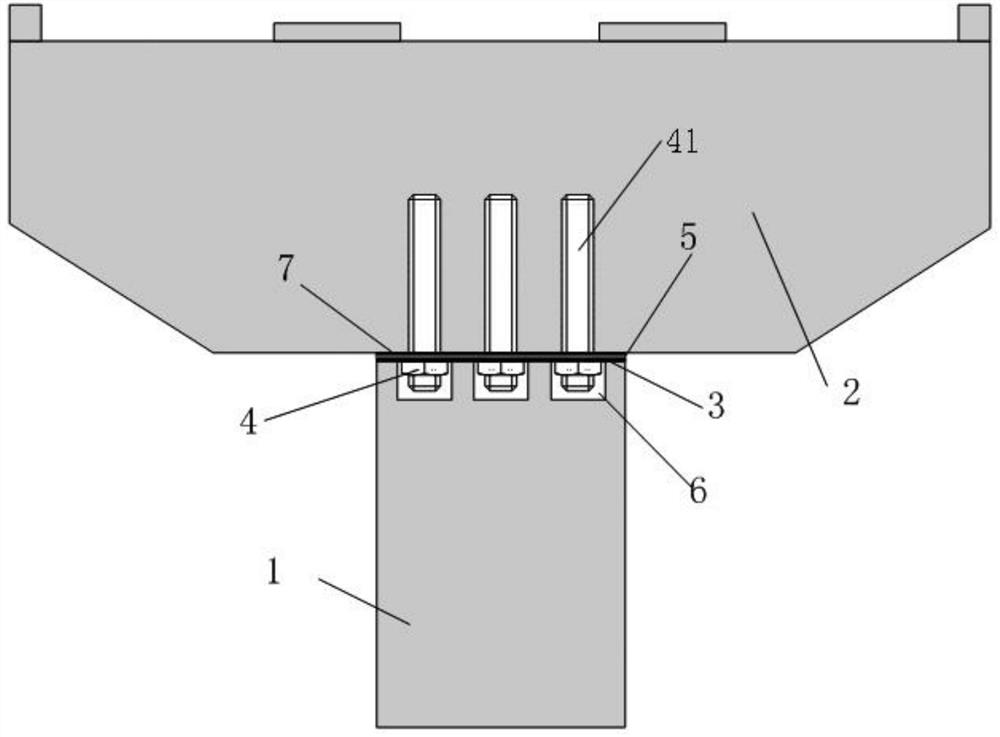

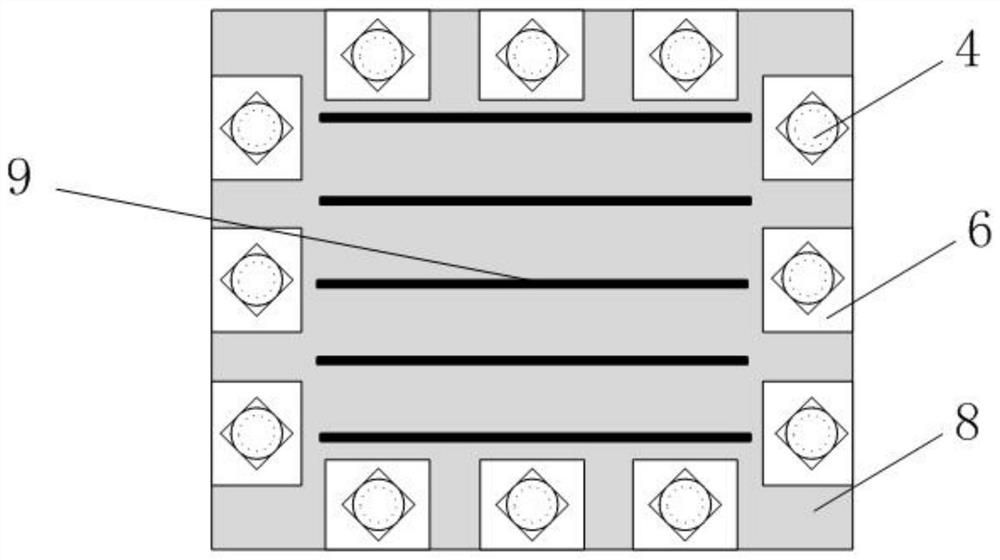

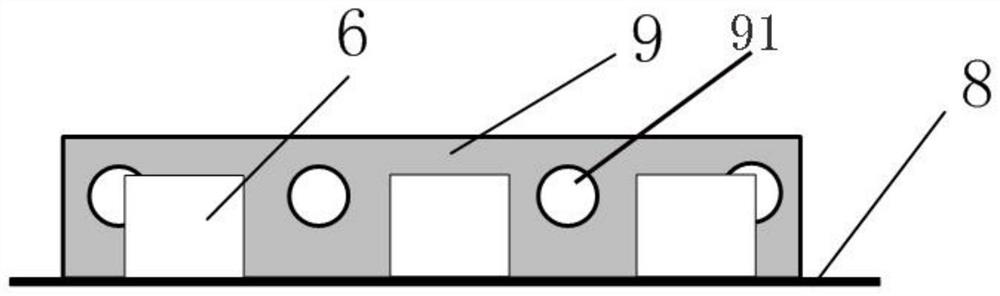

[0030] This example first introduces a synthetic peptide connection system for prefabricated piers of prefabricated girder bridges, combining figure 1 , including prefabricated bridge pier 1, cover beam 2, steel member 3, positioning plate 7, fastener 4, epoxy resin layer 5, prefabricated bridge pier 1, steel member 3, epoxy resin layer 5, positioning plate 7 and cover beam 2 Arranged sequentially from bottom to top, the fasteners 4 run through the positioning plate 7 , the epoxy resin layer 5 and the steel member 3 , and are fixed between the cover beam 2 and the prefabricated pier 1 .

[0031] The prefabricated bridge pier and cover beam connection system provided by this application is mainly composed of prefabricated bridge pier 1, cover beam 2, steel member 3, positioning plate 7, fastener 4, epoxy resin layer 5, steel member 3 is arranged on the prefabricated bridge pier 1 One end of the fastener 4 is fixed to the cover beam 2, and the other end is positioned by the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com