Flow pattern regulator for drilling fluid

A technology of flow pattern regulator and drilling fluid, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of slow activation of organic soil, poor plugging effect, excessive thickening of drilling fluid, etc. Good, good plugging effect, the effect of reducing the amount of percolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A flow regulator for drilling fluid, comprising natural asphalt chemical modifiers, synergists, defoamers, viscosifiers and fluid loss reducers, each component is weighed according to the following mass percentage composition:

[0039] The addition amount of natural asphalt chemical modification is 0.3%;

[0040] The addition amount of synergist is 0.1%;

[0041] The addition of defoamer is 0.1%;

[0042] The addition of tackifier is 0.1%;

[0043] The addition amount of fluid loss reducer is 0.1%;

[0044] The balance is deionized water.

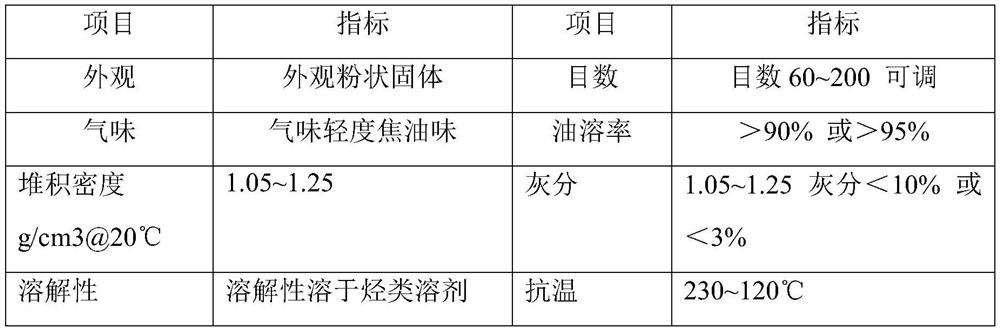

[0045] The natural asphalt chemical modification is a powdery solid made of natural asphalt.

[0046] The tackifier is one or more of alicyclic petroleum resin, rosin, hydrogenated rosin resin or terpene resin.

[0047] The defoamer is polydimethylsiloxane.

[0048] The synergist is Zhuzhijie Z6 type thickener.

[0049] The fluid loss control agent is one or more of lignite resin, sulfomethyl phenolic resin or carboxymethyl st...

Embodiment 2

[0052] A flow regulator for drilling fluid, comprising natural asphalt chemical modifiers, synergists, defoamers, viscosifiers and fluid loss reducers, each component is weighed according to the following mass percentage composition:

[0053] The addition amount of natural asphalt chemical modification is 0.6%;

[0054] The addition amount of synergist is 0.2%;

[0055] The addition of defoamer is 0.1%;

[0056] The addition of tackifier is 0.2%;

[0057] The addition amount of fluid loss reducer is 0.1%;

[0058] The balance is deionized water.

[0059] The natural asphalt chemical modification is a powdery solid made of natural asphalt.

[0060] The tackifier is one or more of alicyclic petroleum resin, rosin, hydrogenated rosin resin or terpene resin.

[0061] The defoamer is polydimethylsiloxane.

[0062] The synergist is Zhuzhijie Z6 type thickener.

[0063] The fluid loss control agent is one or more of lignite resin, sulfomethyl phenolic resin or carboxymethyl st...

Embodiment 3

[0066] A flow regulator for drilling fluid, comprising natural asphalt chemical modifiers, synergists, defoamers, viscosifiers and fluid loss reducers, each component is weighed according to the following mass percentage composition:

[0067] The addition amount of natural asphalt chemical modification is 0.8%;

[0068] The addition amount of synergist is 0.3%;

[0069] The addition of defoamer is 0.2%;

[0070] The addition of tackifier is 0.1%;

[0071] The addition amount of fluid loss reducer is 0.2%;

[0072] The balance is deionized water.

[0073] The natural asphalt chemical modification is a powdery solid made of natural asphalt.

[0074] The tackifier is one or more of alicyclic petroleum resin, rosin, hydrogenated rosin resin or terpene resin.

[0075] The defoamer is polydimethylsiloxane.

[0076] The synergist is Zhuzhijie Z6 type thickener.

[0077] The fluid loss control agent is one or more of lignite resin, sulfomethyl phenolic resin or carboxymethyl st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com