Low-emission low-warpage long glass fiber reinforced polypropylene composite material suitable for automobile skylight guide rail and preparation method and application of composite material

A composite material and a technology for automobile sunroof, which is applied in the field of low emission and low warpage long glass fiber reinforced polypropylene composite material and its preparation, can solve the problems of unfavorable automobile lightweight, complicated preparation process, heavy metal sunroof guide rail, etc. Achieve the effect of reducing the anisotropic orientation gap, reducing the difference, and reducing the degree of warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. The operating methods not indicated in the following examples are generally in accordance with conventional conditions, or in accordance with the conditions suggested by the manufacturer.

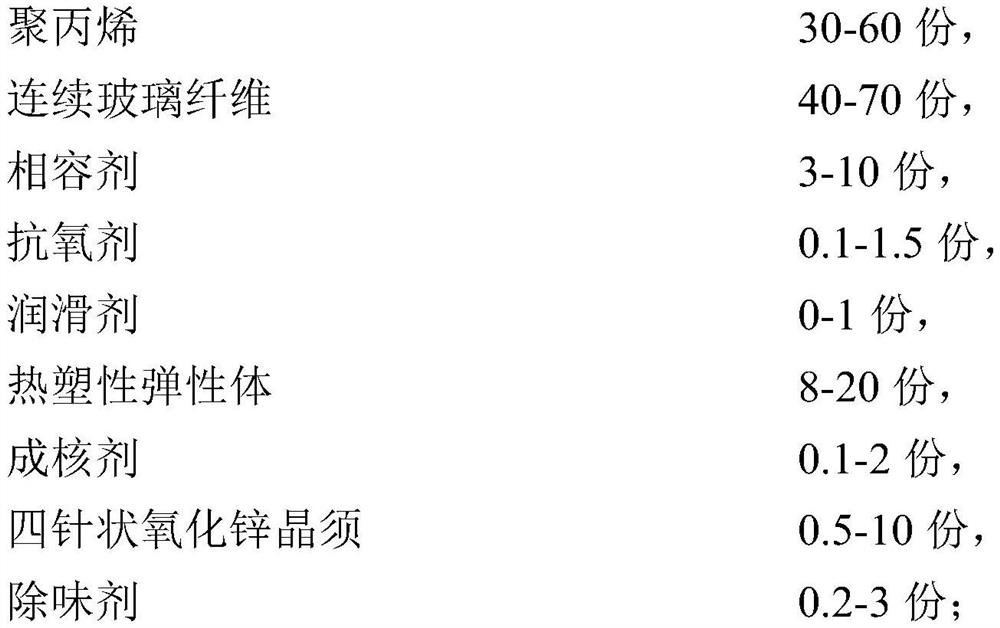

[0037] The raw material proportions of Examples 1-3 and Comparative Examples 1-4 are shown in Table 1 and Table 2 respectively. Unless otherwise specified, the units or parts are parts by weight, and the length of the tetraacicular zinc oxide whisker needles is 10-50 μm, 0.5-5μm at the root of the needle, 20-50 aspect ratio, and 0.2±0.1g / cm apparent density 3 , real density 5.4±0.2g / cm 3 , heat resistance greater than 800 ℃.

[0038] The preparation method of embodiment 1~3 and comparative example 1~4 comprises the following steps:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com