A production method of nanoporous glass for oligonucleotide synthesis

A technology of borosilicate glass and acid solution, which is applied in the field of material processing, can solve the problems of high production cost, uneven channel, environmental pollution and other problems in the production process, and achieve the effects of reducing output ratio, simple operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

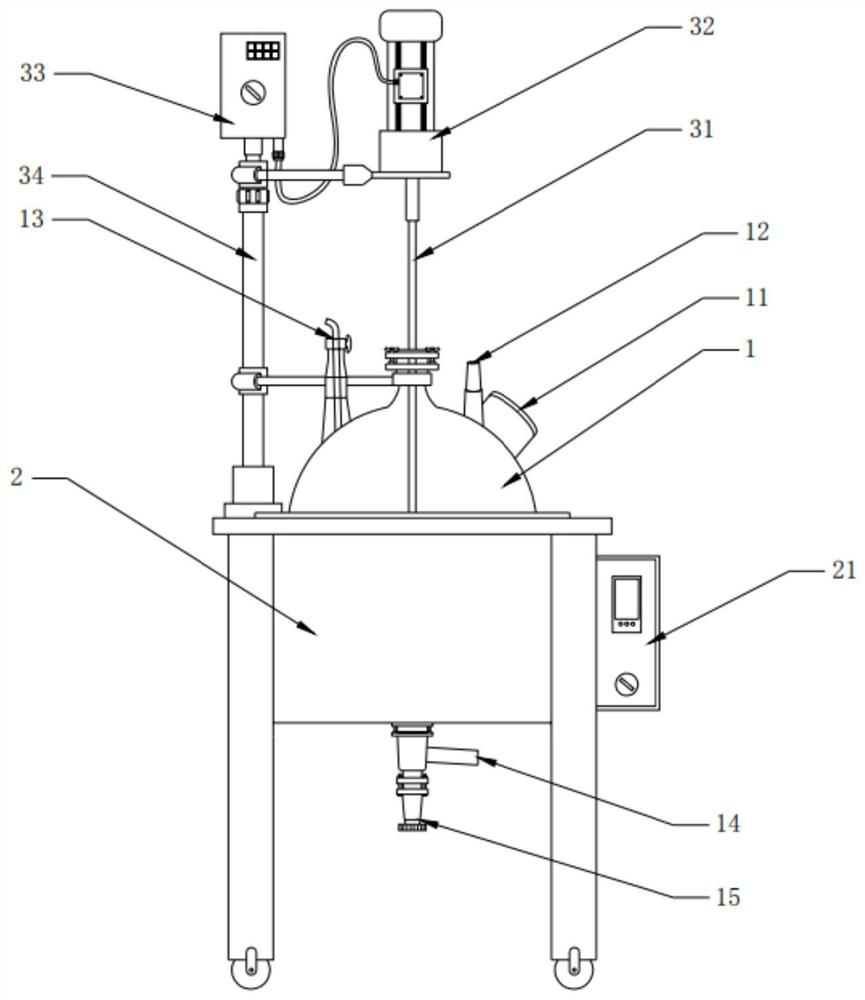

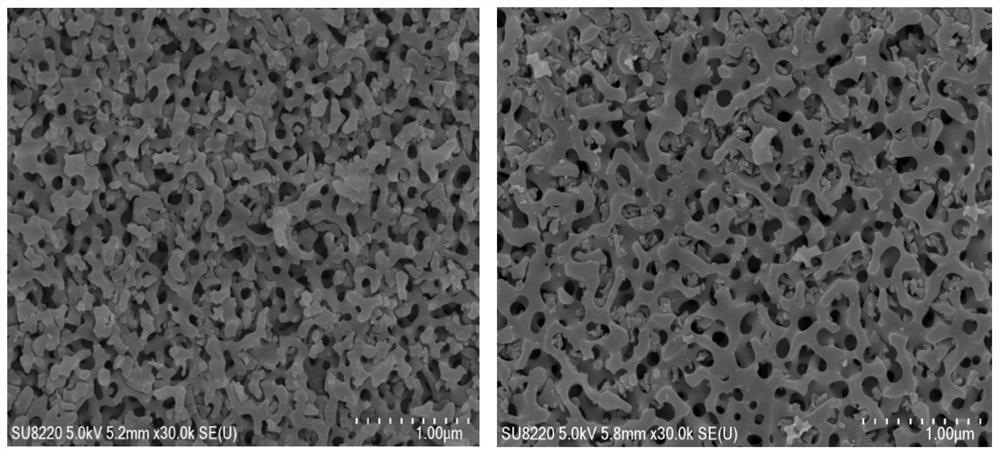

[0080] Embodiment 1: a kind of method of producing CPG

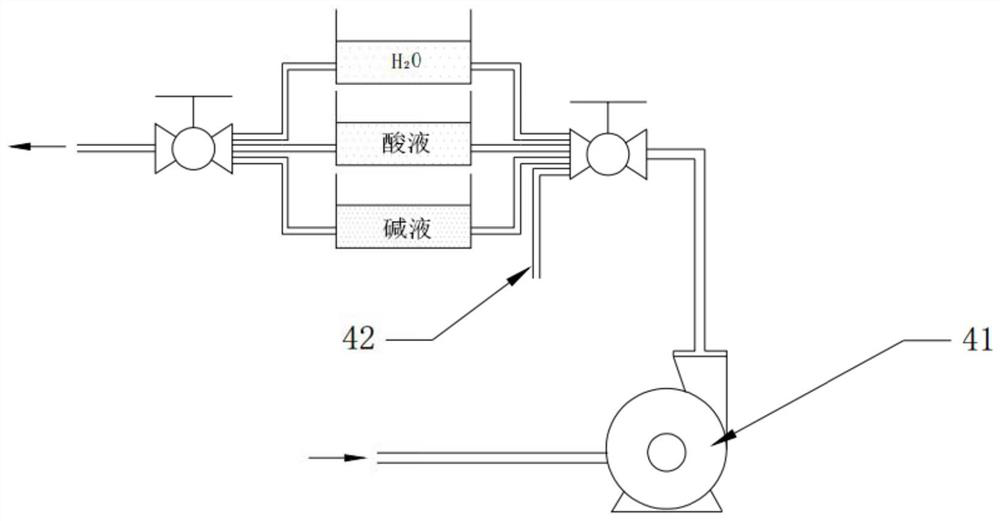

[0081] 1000g of borosilicate glass (80-100 mesh) is placed in a 1L spherical reactor, using a 200-mesh screen, 3L of 1.5mol / L nitric acid is injected into 1L from the top of the spherical reactor through the acid tank through the circulation pump, and the injection is completed Start the oil bath and heat it to 80°C, start the stirring system and adjust the speed to 300 rpm, and stir for 3 hours. This stirring process mainly makes the sodium boron in the borosilicate glass dissolve in the acid. Stop stirring, after the acid liquid in the still is discharged from the waste liquid port, start the circulation pump, the pressure of the circulation pump is 0.5Mpa, pass the acid liquid in the acid liquid tank into the reaction kettle, and circulate for 3 hours, close the acid liquid valve, and put the acid liquid in the still Put the acid solution into the acid solution tank, then open the tank valve, the volume of the tank is...

Embodiment 2

[0083] Embodiment 2: a kind of method of producing CPG

[0084] 5000g of borosilicate glass (80-100 mesh) is placed in a 5L spherical reactor, using a 200-mesh screen, 15L of 0.75mol / L sulfuric acid is injected into 5L from the top of the spherical reactor through the acid tank through the circulation pump, and the injection is complete. Start the oil bath and heat it to 85°C, start the stirring system and adjust the speed to 300 rpm, and stir for 3 hours. This stirring process mainly makes the sodium boron phase in the borosilicate glass dissolve in the acid. Stop stirring, and the acid solution in the kettle After being discharged from the waste liquid port, start the circulation pump, the pressure of the circulation pump is 0.5Mpa, pass the acid solution in the acid solution tank into the reaction kettle, circulate for 3 hours, close the acid solution valve, and pour the remaining acid solution in the tank into the acid solution tank , open the water tank valve, the volume ...

Embodiment 3

[0086] Embodiment 3: a kind of method of producing CPG

[0087]20,000g of borosilicate glass (80-100 mesh) is placed in a 20L spherical reactor, using a 200-mesh screen, 60L of 1.5mol / L hydrochloric acid is injected from the top of the spherical reactor through the acid tank through the circulation pump, and 20L is completed Start the oil bath and heat it to 98°C, start the stirring system and adjust the rotation speed to 300 rpm, and stir for 3 hours. This stirring process mainly makes the sodium boron phase in the borosilicate glass dissolve in the acid. Stop stirring and dissolve the acid solution in the kettle. After being discharged from the waste liquid port, start the circulation pump, the pressure of the circulation pump is 0.5Mpa, pass the acid solution in the acid solution tank into the reaction kettle, circulate for 3 hours, close the acid inlet valve, and pour the remaining acid solution in the tank into the acid solution tank , open the water tank valve, the volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com