A kind of preparation method of selenium nanosheet

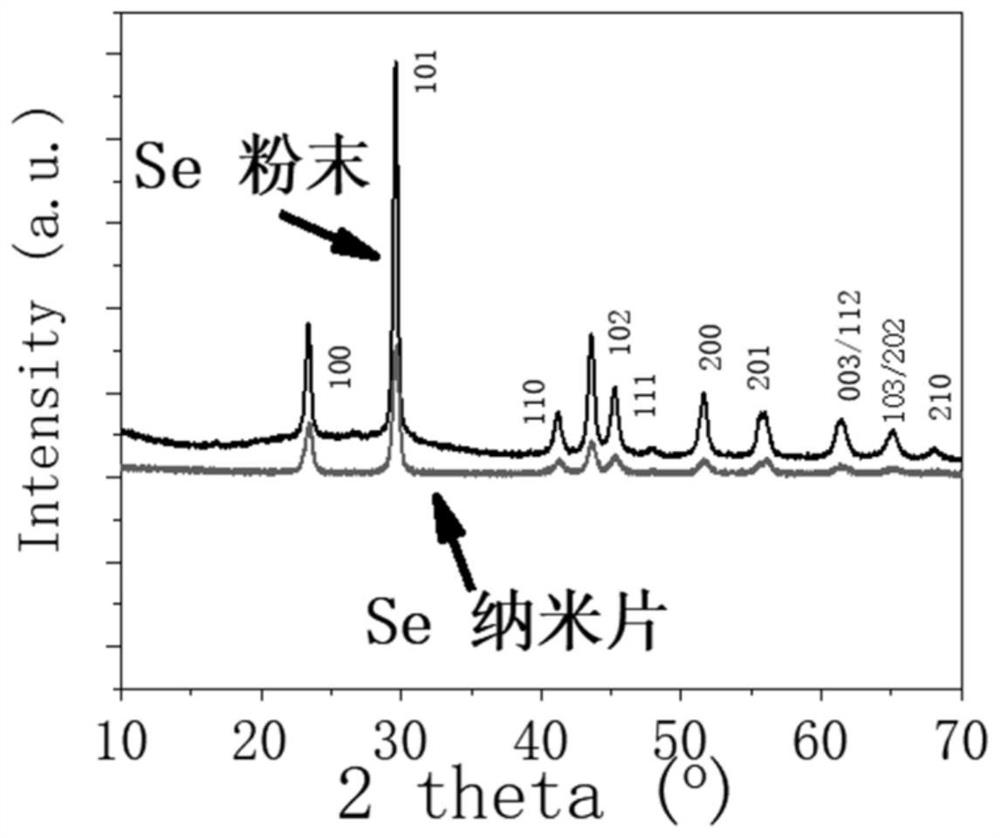

A technology of selenium nanometer and aluminum selenide, which is applied in the field of nanomaterials, can solve the problems of low output of selenium nanosheets, complex preparation process, and harsh conditions, and achieve the effects of small thickness, high environmental stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a preparation method of selenium nanosheets, comprising the following steps:

[0029] Etching: provide a hydrofluoric acid solution with a mass fraction of 5% to 20%, add aluminum selenide to the hydrofluoric acid solution to obtain a hydrofluoric acid mixed system, and transfer the hydrofluoric acid mixed system to 50-20% Stir at 80°C for 1 to 5 hours, after stirring, perform primary centrifugation on the hydrofluoric acid mixed system and collect the precipitate;

[0030] Liquid phase stripping: add the precipitate to the dispersant, and then ultrasonically treat the dispersant with a probe for 4-24 hours. The ultrasonic power of the probe is 200-400W, and the temperature of the dispersant during the ultrasonic probe does not exceed 25 ℃;

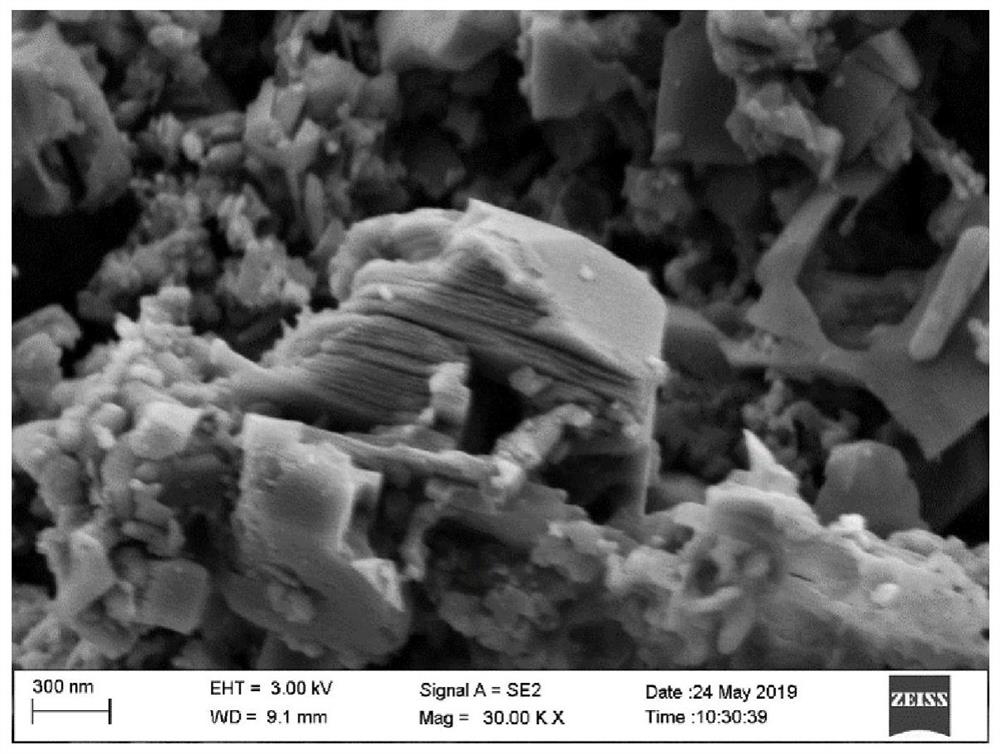

[0031] Collecting the selenium nanosheets by centrifugation: performing secondary centrifugation on the ultrasonicated dispersant, collecting the supernatant to obtain a selenium nanosheet dispersion, and th...

Embodiment 1

[0042] A preparation method of selenium nanosheets, comprising the following steps:

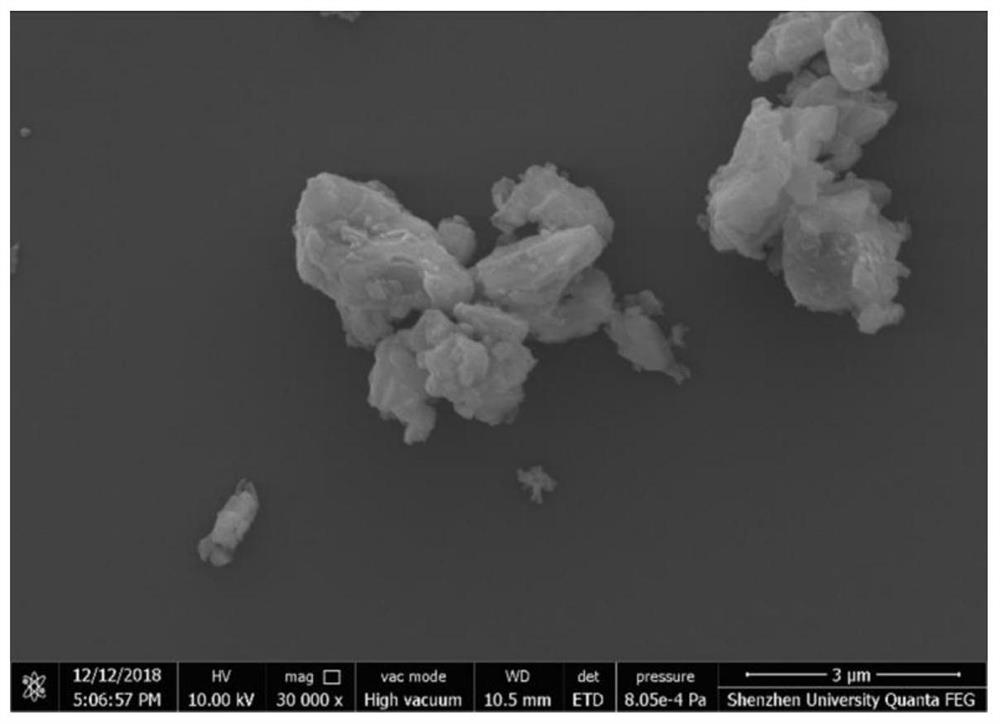

[0043] Etching: 15ml of hydrofluoric acid solution with a mass fraction of 10% was provided, and 100mg of aluminum selenide with a fineness of 200 mesh was added to the hydrofluoric acid solution to obtain a hydrofluoric acid mixed system. Then transfer the hydrofluoric acid mixed system to 65° C. and stir for 2 hours. During the stirring process, the hydrofluoric acid etches the aluminum in the aluminum selenide, thereby obtaining a multilayer microstructure of selenium that has been preliminarily stripped. After the etching, the hydrofluoric acid mixed system was centrifuged at 7500rpm for 10 minutes, and the precipitate was collected after centrifugation, washed three times with deionized water, and dried after washing. This step can effectively remove the residual hydrofluoric acid, prevent the residual hydrofluoric acid from affecting the subsequent liquid phase stripping process, and al...

Embodiment 2

[0050] A preparation method of selenium nanosheets, comprising the following steps:

[0051] Etching: 20ml of hydrofluoric acid solution with a mass fraction of 5% was provided, and 100mg of aluminum selenide with a fineness of 300 mesh was added to the hydrofluoric acid solution to obtain a hydrofluoric acid mixed system. Then transfer the hydrofluoric acid mixed system to 80° C. and stir for 5 hours. During the stirring process, the hydrofluoric acid etches the aluminum in the aluminum selenide, thereby obtaining the multilayer microstructure of the preliminarily exfoliated selenium. After the etching, the hydrofluoric acid mixed system was centrifuged at 10,000 rpm for 5 minutes, and the precipitate was collected after centrifugation, washed three times with deionized water, and dried after washing. This step can effectively remove the residual hydrofluoric acid, prevent the residual hydrofluoric acid from affecting the subsequent liquid phase stripping process, and also he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com