Residual film recycling, rolling and packaging mechanism

A residual film recycling and film rolling technology, applied in collectors, packaging, agricultural machinery and implements, etc., can solve the problems of degradation, low work efficiency, low cleaning rate, etc., achieve reasonable and compact structure design, and improve work efficiency. , the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

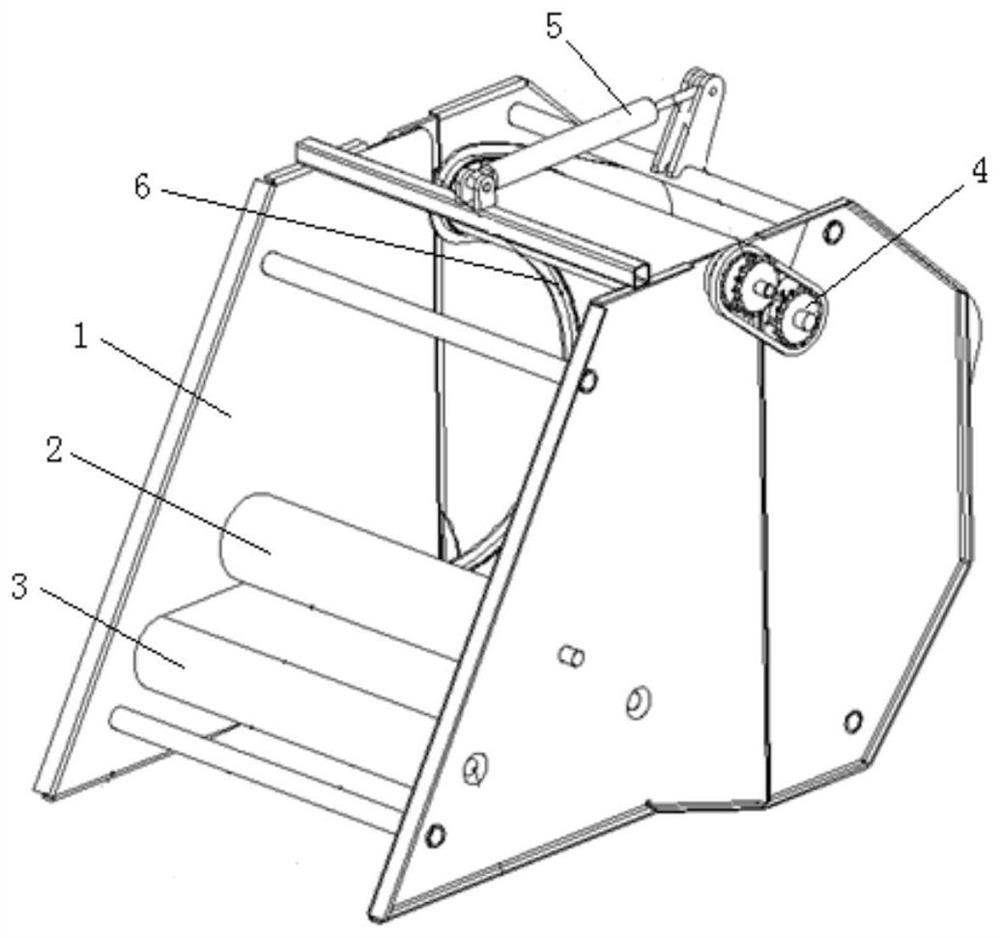

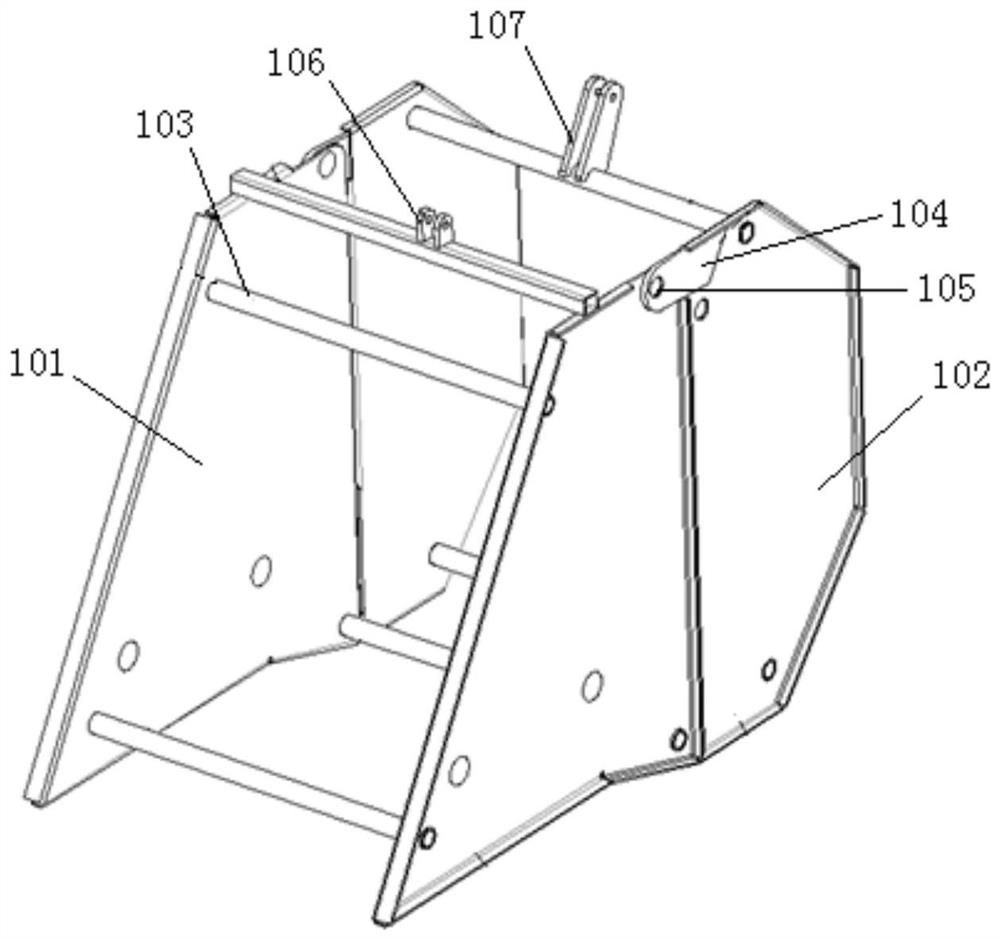

[0029] A kind of residual film recycling film packaging mechanism described in this embodiment is shown in Figure 1 to Figure 9 shown.

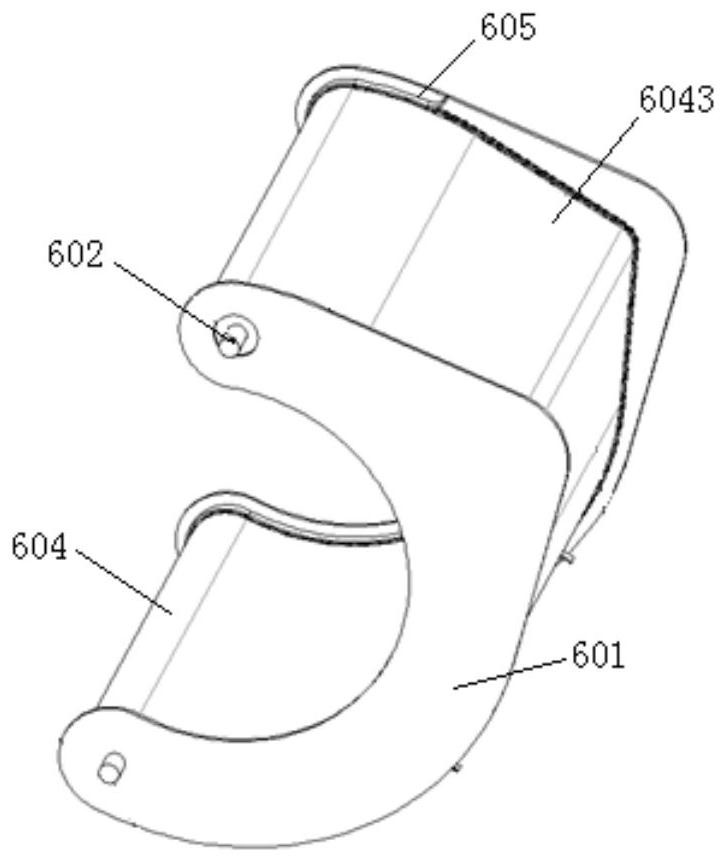

[0030] Such as figure 1 , Figure 5 with Image 6 As shown, a kind of residual film recovery film packaging mechanism described in this embodiment includes a packaging frame 1, a lamination roller 2, a conveyor belt 3, a transmission mechanism 4, a hydraulic cylinder 5, and a residual film packaging belt device 6; Described packing machine frame 1 comprises a fixed front part and a rotatable rear part hinged with the fixed front part, conveyor belt 3 is installed on the fixed front part below packing machine frame 1 with rotating shaft, and lamination cylinder 2 is installed on the fixed front part with rotating shaft. The top of the conveying belt 3 is used to assist the removal of the residual film by pulling and conveying. The auxiliary removal function is that the friction force of the lamination roller 2 gives a tension to the residu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com