Double-ended continuous milling equipment of automobile part crank connecting rods

A technology for auto parts and crank connecting rods, applied in the field of automobile parts manufacturing, can solve the problems of crank connecting rod milling, not considering the fixing mechanism, unfavorable machining accuracy, etc., and achieve the effect of various functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

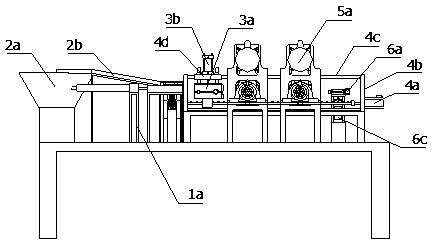

[0023] refer to Figure 1 to Figure 10 The double-end continuous milling equipment for the crank connecting rod of auto parts includes a table 1, a feeding device 2, a fixing device 3, a transmission device 4, a milling device 5 and a discharge device 6, and the table 1 is provided with a fixed Install the support 1a of the transmission device 4, the milling device 5 and the unloading device 6, the fixing device 3 is installed on the discharge port of the feeding device 2 and the fixing device 3 is equipped with a transmission device 4 that drives the fixing device 3 to do horizontal reciprocating motion, The two sides of the transmission device 4 are provided with a plurality of milling devices 5 facing each other, and the side of the end of the transmission device 4 is provided with a discharge device 6, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com