Clamp for machining automobile oil pump valve element

A technology of oil pump and valve core, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

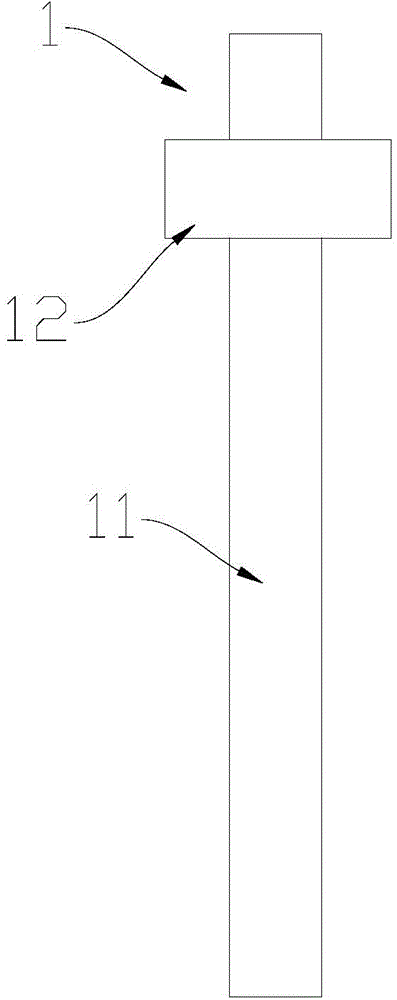

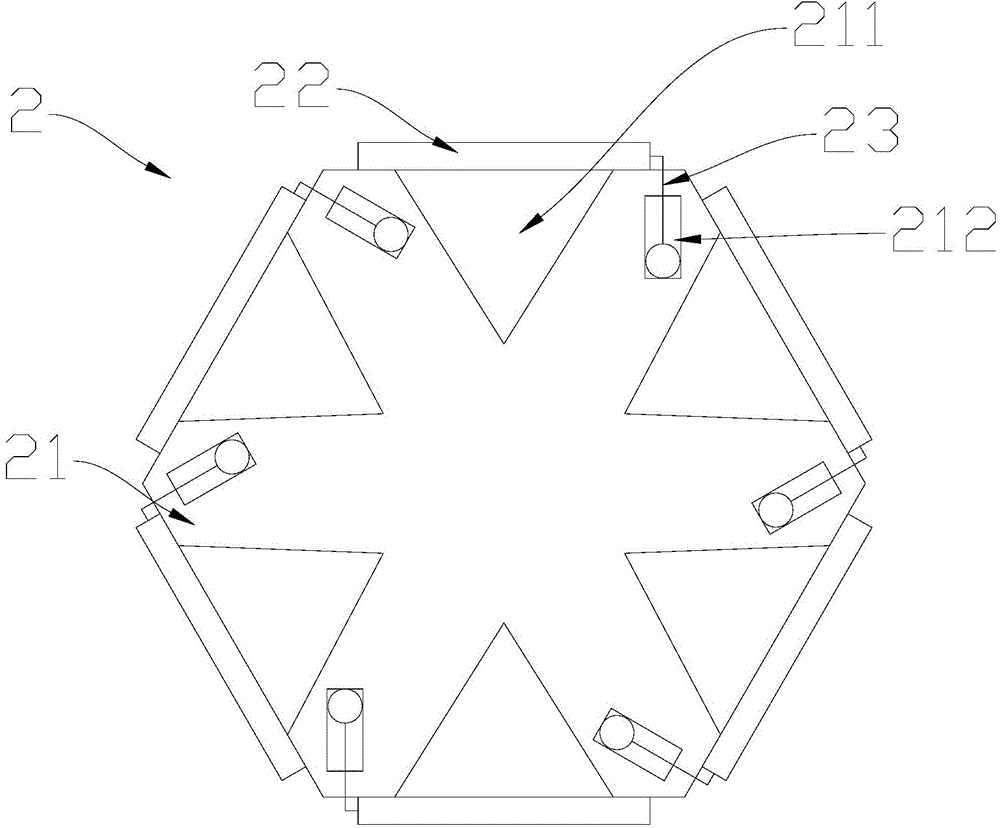

[0015] The invention discloses a fixture 2 for processing a valve core of an automobile oil pump, which comprises a body 21 , a pressing plate 22 and an elastic element 23 .

[0016] figure 2 is the side view of fixture 2. The main body 21 is a regular polygon in a transverse section. exist figure 2 In , the horizontal direction refers to the direction parallel to the paper surface. The body 21 can rotate around its own axis. The own axis of the body 21 is also the central line of the regular polygon, which is parallel to the horizontal axis. The outer wall surface of the body 21 is the surface formed by extending the sides of the regular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com