Method capable of realizing on-line prediction of crystallizer flow field flow state in actual production

A crystallizer and flow state technology, which is applied in the field of online prediction of the flow field and flow state of the crystallizer, can solve the problems of inability to predict the flow field and flow state in the crystallizer on-line, and there is no research on the flow field and flow state system in the crystallizer. To achieve the effect of improving the quality of the slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

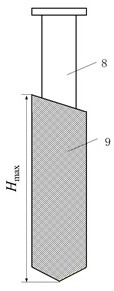

[0037] This embodiment is carried out on a continuous casting machine with a crystallizer cross-sectional size of 1350 mm in width and a thickness of 230 mm. The nozzle size is 140 mm in outer diameter, 80 mm in inner diameter, and 890 mm in length. The outlet is 90 mm high and 70 mm wide. , casting speed 1.0 and 1.4m / min, argon flow rate 10, 12 and 14NL / min. Including the following steps:

[0038] (1) Make steel nail boards: steel nails are 100mm in length and 10mm in diameter, and are evenly distributed in 3 rows × 9 columns on a wooden board with a thickness of 70mm, of which the length of the wooden board is 595mm and the width is 170mm;

[0039] (2) Make the steel nail plate bracket: the length of the pressing piece is 200mm, the width is 50mm, and the height is 10mm;

[0040] (3) Mark the position of the nozzle, the position of the narrow face, the position of the inner and outer arcs and the current casting parameters on the nail plate described in step (1);

[0041] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com