Online moisture meter calibration system and method for cut tobacco preparation link

A moisture meter and tobacco manufacturing technology, applied in the field of tobacco, can solve problems such as the inability to check the accuracy of the moisture meter online and in real time, equipment instability, tobacco quality accidents, etc., to achieve self-learning optimization capabilities, improve prediction accuracy, The effect of improving process quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

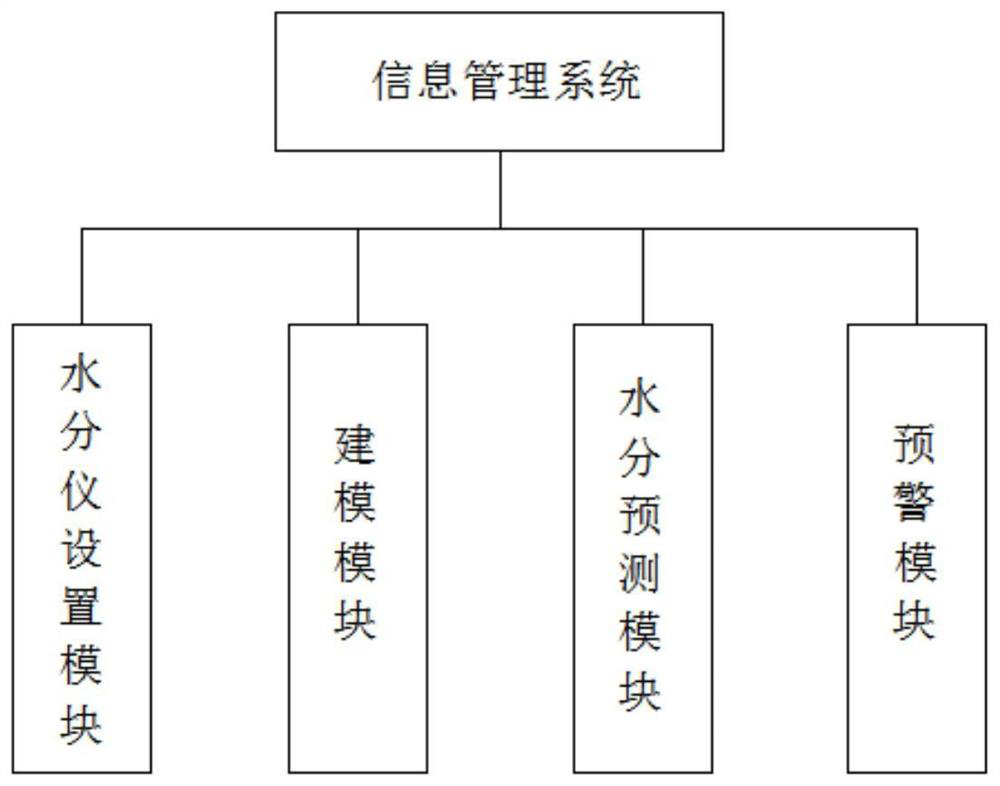

[0061] refer to figure 1 , an online moisture meter calibration system for tobacco silk-making process, including an information management system, which stores historical production data, the historical production data includes historical batch parameters, and historical batch parameters specifically refer to the parameters of each process link of the silk-making production line Process parameters, production parameters, environmental parameters, etc., taking the thin plate silk drying machine in the silk drying process as an example:

[0062] The process parameters include the outlet moisture of the sheet dryer, the inlet moisture of the sheet dryer, and the drum temperature of the sheet dryer; the outlet / entrance moisture is the key index of the system;

[0063] The production parameters include the steam film valve opening of the thin plate drying machine, the hot air temperature of the thin plate drying machine, the moisture discharge opening of the thin plate drying mach...

Embodiment 2

[0120]A method for calibrating an online moisture meter in the tobacco shredded process, the method is applied to the online moisture meter calibration system in the tobacco shredded process described in Example 1, which includes the following steps:

[0121] Step 1, data collection

[0122] Data source: corresponding historical production data in the silk production line information management system;

[0123] Step 2, production line moisture meter settings

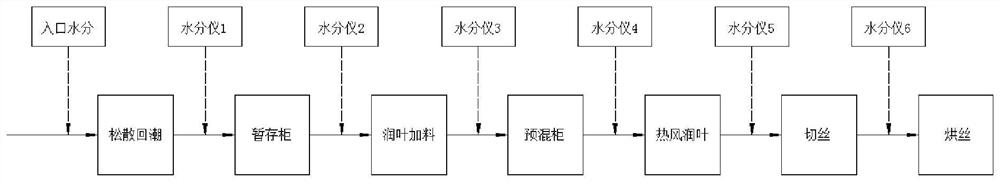

[0124] The moisture meter setting module is placed at the front end of the loose moisture recovery, temporary storage cabinet, leaf moistening feeding, premixing cabinet, hot air moistening leaf, shredding, and shred drying processes of the silk production line, and defines each moisture meter;

[0125] Step three, model building

[0126] Through the modeling module, the verification model of the loose moisture regain moisture meter, the verification model of the leaf moistening moisture meter, and the hot air leaf moi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com