A composite nano-film material and gas sensing element based on graphene quantum dot functionalization

A nano-film material, graphene quantum dot technology, applied in analysis materials, material resistance, metal material coating technology and other directions, can solve problems such as unfavorable high-performance sensing materials, and achieve improved sensitivity, good application prospects, and good repeatability. sexual effect

Active Publication Date: 2022-05-31

NANJING UNIV OF INFORMATION SCI & TECH

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to its own characteristics, the size of the nanoparticles in the nanostructures usually prepared by the hydrothermal synthesis method is more than 10 nanometers, which is not conducive to obtaining high-performance sensing materials.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

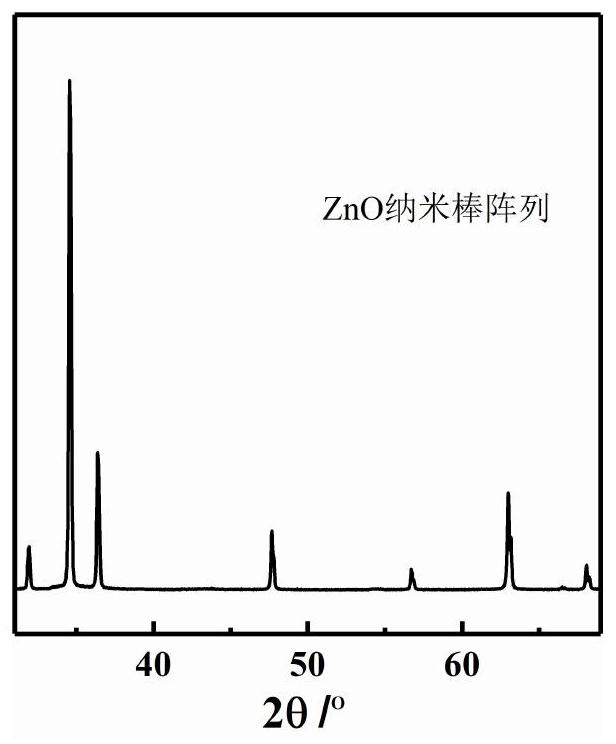

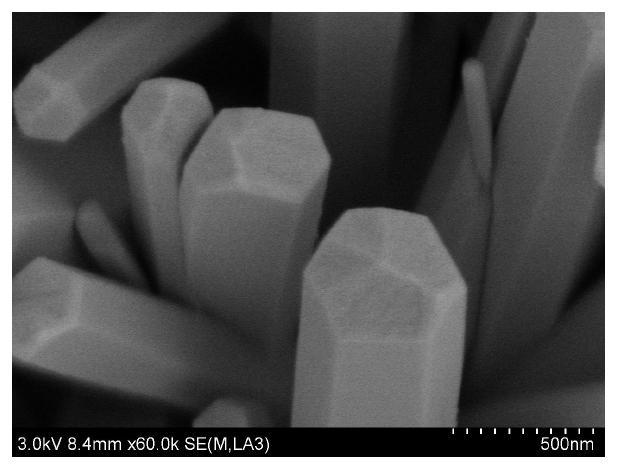

[0050] As shown in Figure 2 and Figure 4, the composite film on the surface of the sensor device prepared is mainly composed of ZnO, in the shape of nano-sheets,

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Login to View More

Abstract

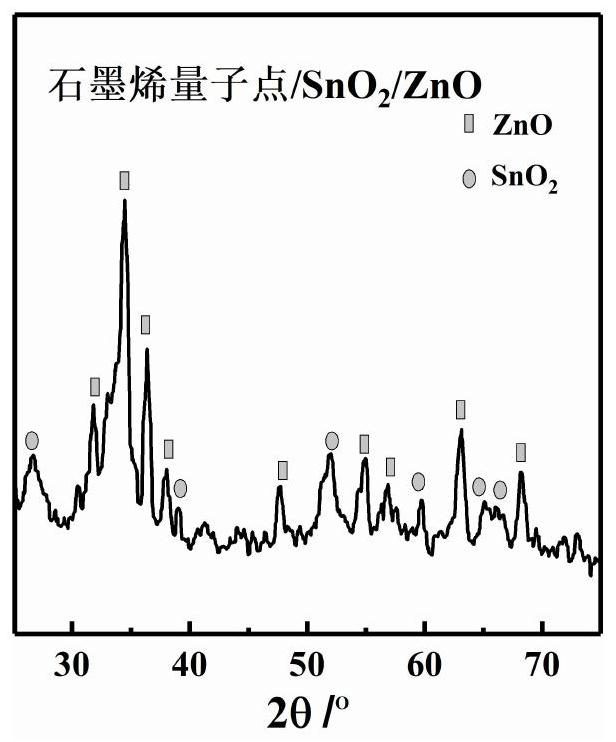

The invention discloses a composite nano-film material based on the functionalization of graphene quantum dots. The composite nano-film material is in the shape of a film, the main body is ZnO nanosheets, and the surface is covered with graphene quantum dots and tin dioxide quantum grains; as The main ZnO nanosheets are hexagonal, with an average side length of 1.5-2.4 μm and an average thickness of 50-100 nm; the average size of graphene quantum dots is 3.2-4.3 nm, and the average size of tin dioxide quantum grains is 3.5- 5.2nm. The invention comprehensively uses the hydrothermal method and the post-heat steaming method to prepare the multi-level structure sensing material, and the synthesis method is simple and the cost is low.

Description

A kind of composite nano film material based on graphene quantum dot functionalization and gas sensor inductive element technical field The present invention relates to the technical field of semiconductor oxide gas sensors, in particular to a kind of use based on the amount of graphene Gas sensing element of subdot-functionalized composite nanofilm material. Background technique [0002] The non-invasive diagnostic technology based on metal oxide semiconductor gas sensors has the advantages of fast dynamic process, low cost, and high reliability. Good portability and other advantages. Real-time detection of biomarkers in exhaled breath has become a hot research topic. These sensors can By detecting the presence of specific volatile organic compounds (VOCs, volatile organic compounds) in human exhaled breath compounds, volatile organic compounds) as disease biomarkers to diagnose diseases, VOCs are strongly associated with specific diseases sex. Previous studies...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N27/12C23C14/14C23C14/35C23C14/58C23C26/00C23C28/04

CPCG01N27/127C23C14/14C23C14/35C23C14/5853C23C26/00C23C28/04Y02A50/20

Inventor 邵绍峰林纪栋夏雨萱刘星宇

Owner NANJING UNIV OF INFORMATION SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com