Preparation method of bamboo pulp, bamboo pulp and fibers

A technology of bamboo pulp and bamboo fiber, which is applied in the processing of fiber raw materials, pulping of cellulose raw materials, post-processing of cellulose pulp, etc., can solve the problems of poor fiber quality and low bamboo pulp quality, and achieve better fiber quality. , high whiteness, high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation Process:

[0028] (1) material preparation: get an appropriate amount of bamboo for subsequent use;

[0029] (2) material cutting: adopt the mode of oblique cutting to cut the bamboo of step (1), length is controlled at 20mm;

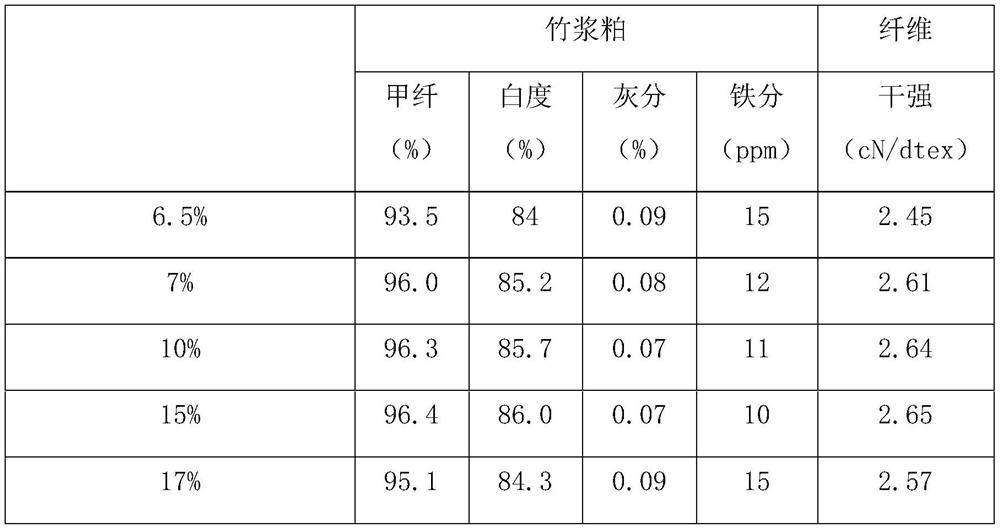

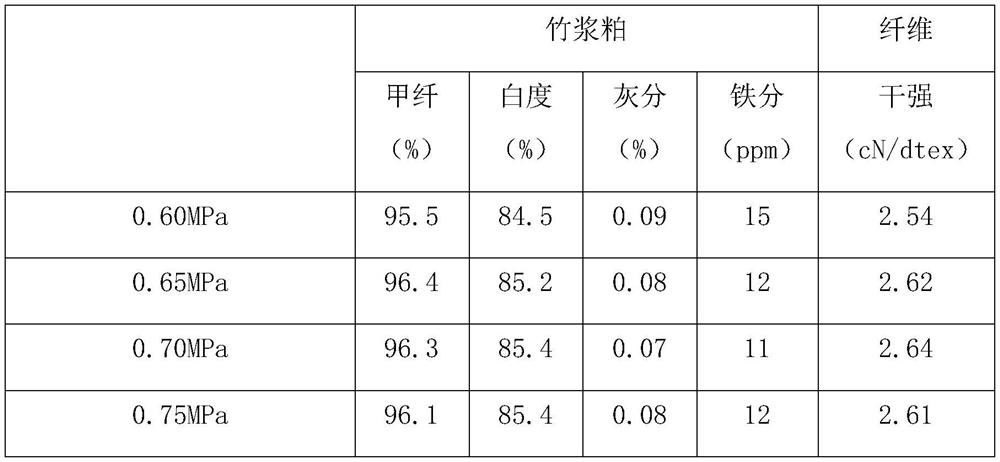

[0030] (3) Cooking: adding the bamboo material of step (2) into the container for cooking, the cooking liquid is a sodium hydroxide solution with a concentration of 15%, the cooking pressure is 0.7MPa, the cooking temperature is 168°C, and the cooking time is 130min;

[0031] (4) bleaching: the product of step (3) is bleached, the bleaching solution is a hydrogen peroxide solution with a concentration of 1.5%, the bleaching temperature is 65°C, and the bleaching time is 100min;

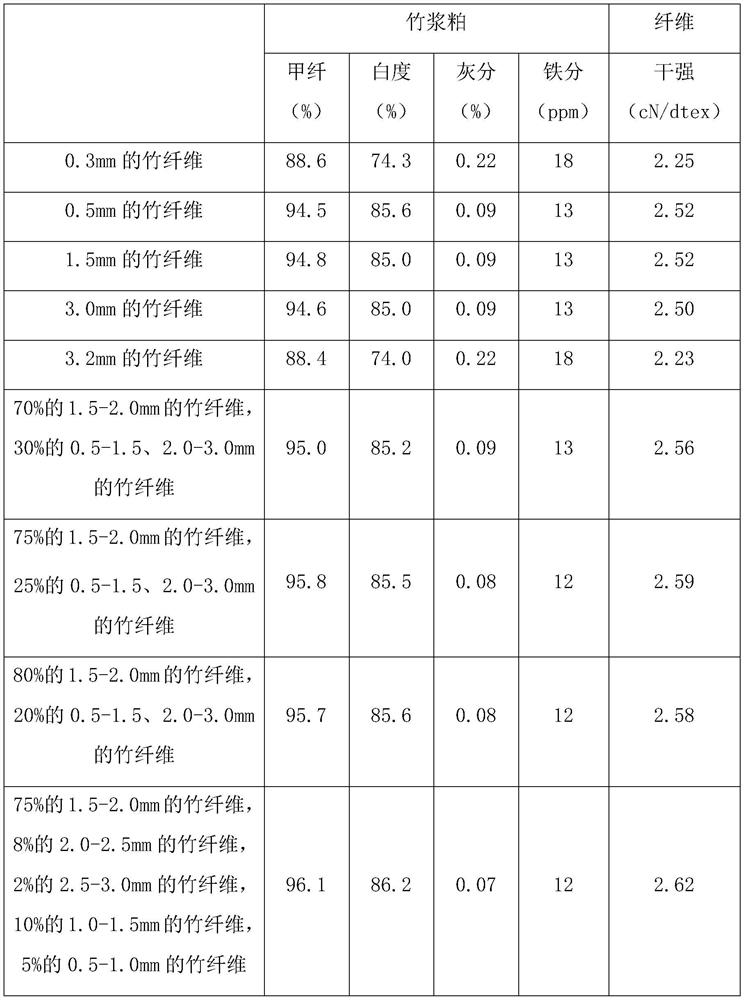

[0032] (5) classification: utilize classification sieve to screen out the bamboo fiber of 0.5mm from the product of step (4);

[0033] (6) copying: the bamboo fiber of step (5) is copied into bamboo pulp.

[0034] Product performance:

[0035] In the bamb...

Embodiment 2

[0038] Preparation Process:

[0039] (1) material preparation: get an appropriate amount of bamboo for subsequent use;

[0040] (2) material cutting: adopt the mode of oblique cutting to cut the bamboo of step (1), length is controlled at 25mm;

[0041](3) Cooking: adding the bamboo material of step (2) into the container for cooking, the cooking liquid is a sodium hydroxide solution with a concentration of 15%, the cooking pressure is 0.75MPa, the cooking temperature is 169°C, and the cooking time is 130min;

[0042] (4) bleaching: the product of step (3) is bleached, the bleaching solution is a hydrogen peroxide solution with a concentration of 1.5%, the bleaching temperature is 65°C, and the bleaching time is 100min;

[0043] (5) classification: utilize classification sieve to screen out the bamboo fiber of 1.5mm from the product of step (4);

[0044] (6) copying: the bamboo fiber of step (5) is copied into bamboo pulp.

[0045] Product performance:

[0046] In the bamb...

Embodiment 3

[0049] Preparation Process:

[0050] (1) material preparation: get an appropriate amount of bamboo for subsequent use;

[0051] (2) material cutting: adopt the mode of oblique cutting to cut the bamboo of step (1), length is controlled at 25mm;

[0052] (3) Cooking: adding the bamboo material of step (2) into the container for cooking, the cooking liquid is a sodium hydroxide solution with a concentration of 15%, the cooking pressure is 0.7MPa, the cooking temperature is 165°C, and the cooking time is 130min;

[0053] (4) Bleaching: the product of step (3) is bleached, the bleaching solution is a hydrogen peroxide solution with a concentration of 1.5%, the bleaching temperature is 70°C, and the bleaching time is 100min;

[0054] (5) classification: utilize classification sieve to screen out the bamboo fiber of 3.0mm from the product of step (4);

[0055] (6) copying: the bamboo fiber of step (5) is copied into bamboo pulp.

[0056] Product performance:

[0057] In the bamb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com