A catalyst modification method for improving the yield of biomass catalytic pyrolysis hydrocarbons

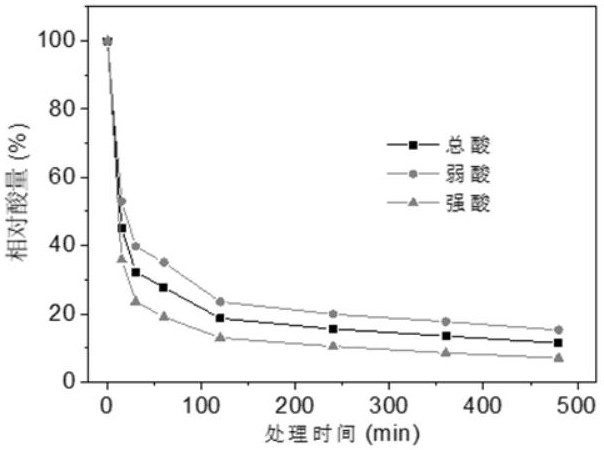

A catalytic pyrolysis and catalyst technology, applied in the field of biomass resource conversion and utilization, can solve the problems of reducing the yield of hydrocarbon target products, catalyst deactivation, blocking pores, etc., so as to improve catalytic performance, reduce acid content and acid strength , the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

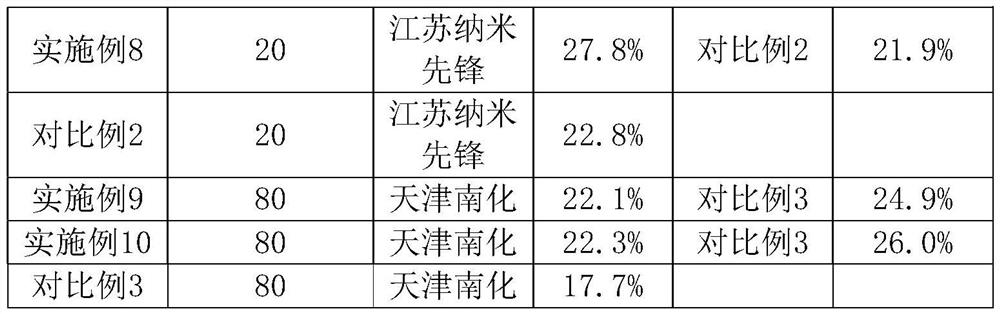

[0021] SiO will be purchased from Tianjin Nanhua Catalyst Co., Ltd. 2 / Al 2 o 3 The powdered HZSM-5 molecular sieve with a ratio of 38 is compressed into tablets under a pressure of 30MPa, and then crushed and sieved to obtain particles with a particle size range of 0.3-0.9mm; the HZSM-5 shaped particles are placed in a volume percentage of 60% water vapor + In a carrier gas atmosphere of 40% nitrogen, treat at 550°C for 15 minutes; place the HZSM-5 shaped particles after steam treatment in an air atmosphere at 600°C for 1 hour, and obtain the modified HZSM-5 catalyst after cooling.

[0022] Catalyst performance is tested by biomass catalytic pyrolysis reaction on a fluidized bed / fixed bed two-stage reactor, in which the first stage reactor is a fluidized bed reactor for rapid pyrolysis of biomass to generate pyrolysis steam, and the second stage reaction The device is a fixed-bed reactor, which is used to load HZSM-5 catalyst to convert biomass pyrolysis steam into hydrocar...

Embodiment 2

[0025] SiO will be purchased from Tianjin Nanhua Catalyst Co., Ltd. 2 / Al 2 o 3 The powdered HZSM-5 molecular sieve with a ratio of 38 is compressed into tablets under a pressure of 30MPa, and then crushed and sieved to obtain particles with a particle size range of 0.3-0.9mm; the HZSM-5 shaped particles are placed in a volume percentage of 60% water vapor + In a carrier gas atmosphere of 40% nitrogen, treat at 550°C for 30 minutes; place the HZSM-5 shaped particles after water vapor treatment in an air atmosphere at 600°C for 1 hour, and obtain the modified HZSM-5 catalyst after cooling.

[0026] The catalyst performance test method is the same as that in Example 1. After the reaction, the gas chromatographic analyzer is used to quantitatively analyze the hydrocarbon target products. The results show that the carbon yield of the hydrocarbon target products relative to the biomass raw material is 25.3%.

Embodiment 3

[0028] SiO will be purchased from Tianjin Nanhua Catalyst Co., Ltd. 2 / Al 2 o 3 The powdered HZSM-5 molecular sieve with a ratio of 38 is compressed into tablets under a pressure of 30MPa, and then crushed and sieved to obtain particles with a particle size range of 0.3-0.9mm; the HZSM-5 shaped particles are placed in a volume percentage of 60% water vapor + In a carrier gas atmosphere of 40% nitrogen, treat at 550°C for 60 minutes; place the HZSM-5 shaped particles after water vapor treatment in an air atmosphere at 600°C for 1 hour, and obtain the modified HZSM-5 catalyst after cooling.

[0029] The catalyst performance test method is the same as in Example 1. After the reaction, the gas chromatographic analyzer is used to quantitatively analyze the hydrocarbon target products. The results show that the carbon yield of the hydrocarbon target products relative to the biomass raw material is 25.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com