Preparation method of cutting fluid for metal processing

A technology for metal processing and cutting fluid, applied in the field of preparation of cutting fluid for metal processing, can solve problems such as affecting production efficiency and efficiency, affecting enterprise production efficiency, reducing processing speed, etc., and achieving extended tool life, low density, and increased cooling. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

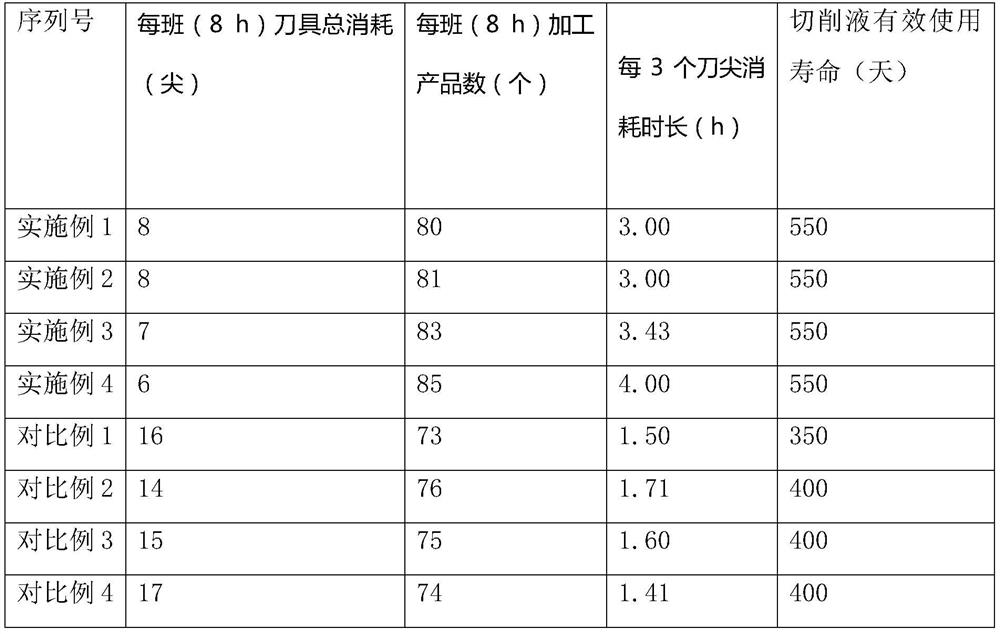

Examples

Embodiment 1

[0036] A method for preparing cutting fluid for metal processing, comprising the following steps:

[0037] (1) Weighing: Use an electronic scale with an accuracy of 0.001g to weigh the raw materials that make up the cutting fluid for metal processing according to the ratio;

[0038] (2) Stirring: put each raw material of cutting fluid for metal processing into a stirring tank and stir evenly to obtain a mixture;

[0039] (3) Primary cooling: Put the mixture into the temperature of -25°C and cool it for 15 minutes to obtain the primary cooling mixture;

[0040] (4) Secondary cooling: Put the primary cooling mixture into the temperature of -5°C and cool it for 20 minutes to obtain the secondary cooling mixture;

[0041] (5) Tertiary cooling: put the secondary cooled mixture into the temperature of -15°C and cool it for 10 minutes to obtain the tertiary cooled mixture;

[0042] (6) Reactor reaction: put the three-stage cooling mixture into the reactor, mix and stir for 5 minute...

Embodiment 2

[0054] A method for preparing cutting fluid for metal processing, comprising the following steps:

[0055] (1) Weighing: Use an electronic scale with an accuracy of 0.001g to weigh the raw materials that make up the cutting fluid for metal processing according to the ratio;

[0056] (2) Stirring: put each raw material of cutting fluid for metal processing into a stirring tank and stir evenly to obtain a mixture;

[0057] (3) Primary cooling: Put the mixture into the temperature of -20°C and cool it for 20 minutes to obtain the primary cooling mixture;

[0058] (4) Secondary cooling: put the mixture of primary cooling into the temperature of 0 ℃ and cool for 25 minutes to obtain the mixture of secondary cooling;

[0059] (5) Tertiary cooling: put the secondary cooled mixture into -10°C for cooling for 20 minutes to obtain a tertiary cooled mixture;

[0060] (6) Reactor reaction: put the three-stage cooling mixture into the reactor, mix and stir for 15 minutes under the condit...

Embodiment 3

[0072] A method for preparing cutting fluid for metal processing, comprising the following steps:

[0073] (1) Weighing: Use an electronic scale with an accuracy of 0.001g to weigh the raw materials that make up the cutting fluid for metal processing according to the ratio;

[0074] (2) Stirring: put each raw material of cutting fluid for metal processing into a stirring tank and stir evenly to obtain a mixture;

[0075] (3) Primary cooling: put the mixture into the temperature of -22°C and cool it for 18 minutes to obtain the primary cooling mixture;

[0076] (4) Secondary cooling: put the mixture of primary cooling into the temperature of -3°C for cooling for 23 minutes to obtain the mixture of secondary cooling;

[0077] (5) Tertiary cooling: put the mixture of secondary cooling into the temperature of -12°C and cool for 15 minutes to obtain the mixture of tertiary cooling;

[0078] (6) Reactor reaction: put the three-stage cooled mixture into the reactor, mix and stir fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com