Silsesquioxane modified bifunctional polyester resin and preparation method thereof

A silsesquioxane, bifunctional technology, applied in the field of polyester resin, can solve the problems of defects in storage stability, poor compatibility, large differences in solubility parameters between polyester resin and silsesquioxane, etc. Good performance, good resistance to organic solvents, and the effect of improving the phenomenon of polygel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment a

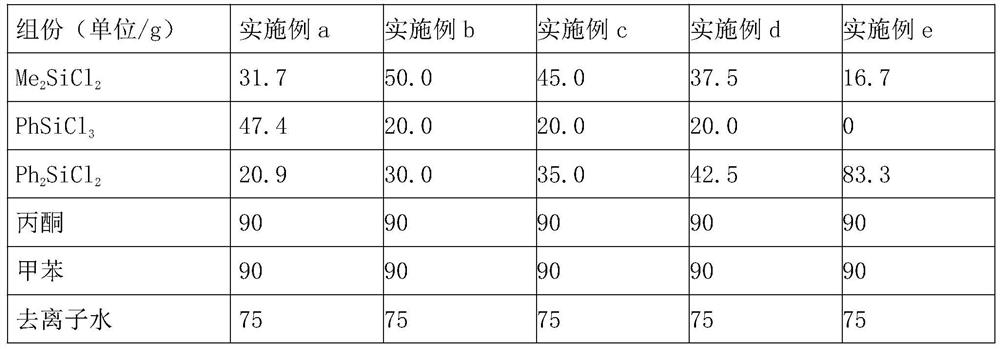

[0067] In a 1000ml four-neck flask equipped with a stirrer, condenser, thermometer and nitrogen protection, add 90 parts of toluene, 90 parts of acetone mixed solvent, maintain the reaction temperature range of 0-3 ℃, and add 31.7 parts of Me 2 SiCl 2 , 47.4 parts of PhSiCl 3 , 20.9 Ph 2 SiCl 2 The prepared mixture; under stirring, use a constant pressure funnel to slowly drop 75 parts of deionized water, maintain the reaction temperature range of 42-45 ° C, stir for 0.5 h, let stand to separate layers, and exclude acid water; the organic layer is washed to neutral; The solvent was distilled off under reduced pressure, and cooled to room temperature for later use.

Embodiment b

[0069] In a 1000ml four-neck flask equipped with a stirrer, condenser, thermometer and nitrogen protection, add 90 parts of toluene, 90 parts of acetone mixed solvent, maintain the reaction temperature range of 0-3 °C, and add 50.0 parts of Me 2 SiCl 2 , 20.0 parts PhSiCl 3 , 30.0 parts Ph 2 SiCl 2 The prepared mixture; under stirring, use a constant pressure funnel to slowly drop 75 parts of deionized water, maintain the reaction temperature range of 42-45 ° C, stir for 0.5 h, let stand to separate layers, and exclude acid water; the organic layer is washed to neutral; The solvent was distilled off under reduced pressure, and cooled to room temperature for later use.

Embodiment c

[0071] In a 1000ml four-neck flask equipped with a stirrer, condenser, thermometer and nitrogen protection, add 90 parts of toluene, 90 parts of acetone mixed solvent, maintain the reaction temperature range of 0-3 ℃, and add 45.0 parts of Me 2 SiCl 2 , 20.0 parts PhSiCl 3 , 35.0 parts Ph 2 SiCl 2 The prepared mixture; under stirring, use a constant pressure funnel to slowly drop 75 parts of deionized water, maintain the reaction temperature range of 42-45 ° C, stir for 0.5 h, let stand to separate layers, and exclude acid water; the organic layer is washed to neutral; The solvent was distilled off under reduced pressure, and cooled to room temperature for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com