Hydrophilic hollow porous microsphere resin for adsorption treatment of printing and dyeing wastewater, preparation method and application thereof

A technology for printing and dyeing wastewater, adsorption treatment, applied in adsorption water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

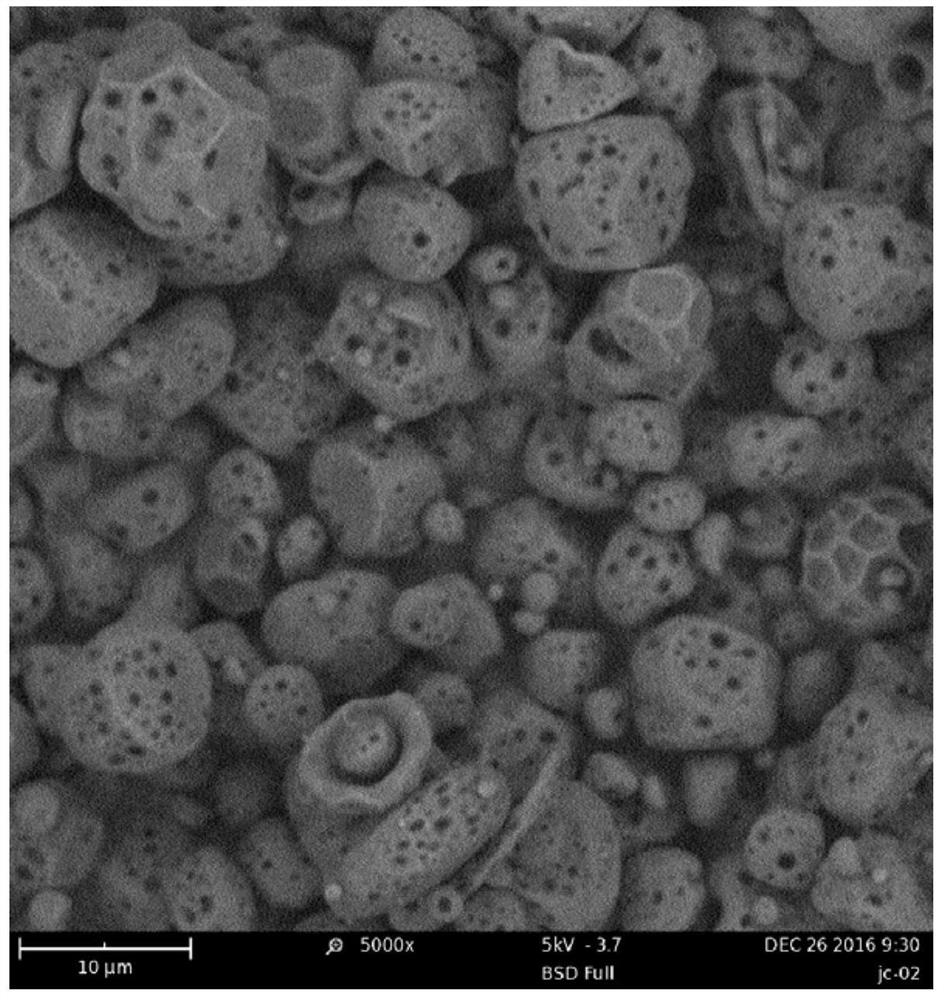

Image

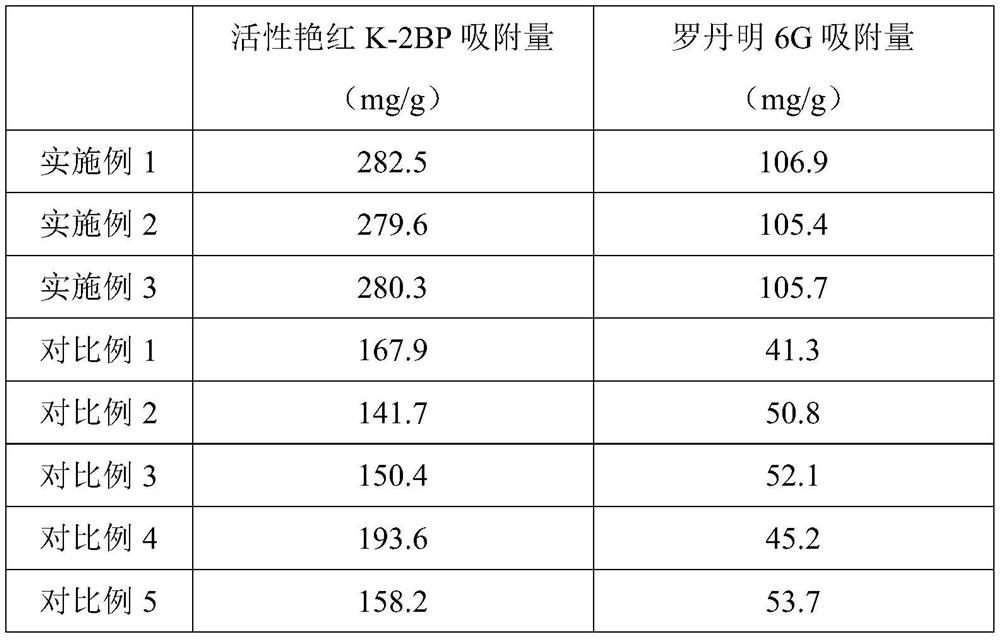

Examples

Embodiment 1

[0031] The preparation method of the hydrophilic hollow porous microsphere resin for adsorption treatment of printing and dyeing wastewater comprises the following steps:

[0032] (1) Take 20.0g of sodium p-styrenesulfonate, 12.0g of acrylamide, 25.0g of dimethyl diallyl ammonium chloride, 25.0g of divinylbenzene, 50.0g of porogen, and 1.0g of benzoyl peroxide Mix evenly to obtain an oil phase; the porogen is composed of toluene and n-hexane in a volume ratio of 1:0.4;

[0033] (2) Take 4.0 g of polyvinyl alcohol, 9.0 g of gelatin, and 195.0 g of sodium chloride and add them into 1000 mL of water and mix evenly to obtain an aqueous phase;

[0034] (3) Add the oil phase to the water phase, stir at a speed of 60r / min until the particle size of the oil beads is 1.3mm, raise the temperature to 78°C at a heating rate of 0.5°C / min and react at a constant temperature for 2 hours, then increase the temperature at a rate of 0.5°C ℃ / min to raise the temperature to 88°C and react at a c...

Embodiment 2

[0036] The preparation method of the hydrophilic hollow porous microsphere resin for adsorption treatment of printing and dyeing wastewater comprises the following steps:

[0037] (1) Take 18.0g of sodium p-styrenesulfonate, 10.0g of acrylamide, 24.0g of dimethyl diallyl ammonium chloride, 20.0g of divinylbenzene, 40.0g of porogen, and 0.5g of benzoyl peroxide Mix evenly to obtain an oil phase; the porogen is composed of toluene and n-hexane in a volume ratio of 1:0.4;

[0038] (2) Take 3.5g of polyvinyl alcohol, 8.0g of gelatin, and 190.0g of sodium chloride, add them into 950mL of water and mix well to obtain the water phase;

[0039](3) Add the oil phase to the water phase, stir at a speed of 60r / min until the particle size of the oil beads is 1.3mm, raise the temperature to 78°C at a heating rate of 0.5°C / min and react at a constant temperature for 2 hours, then increase the temperature at a rate of 0.5°C ℃ / min to raise the temperature to 88°C and react at a constant temp...

Embodiment 3

[0041] The preparation method of the hydrophilic hollow porous microsphere resin for adsorption treatment of printing and dyeing wastewater comprises the following steps:

[0042] (1) Take 22.0g of sodium p-styrenesulfonate, 15.0g of acrylamide, 26.0g of dimethyl diallyl ammonium chloride, 30.0g of divinylbenzene, 60.0g of porogen, and 2.0g of benzoyl peroxide Mix evenly to obtain an oil phase; the porogen is composed of toluene and n-hexane in a volume ratio of 1:0.4;

[0043] (2) Take 4.5g of polyvinyl alcohol, 10.0g of gelatin, 200.0g of sodium chloride and add it into 1050mL of water and mix evenly to obtain the water phase;

[0044] (3) Add the oil phase to the water phase, stir at a speed of 60r / min until the particle size of the oil beads is 1.3mm, raise the temperature to 78°C at a heating rate of 0.5°C / min and react at a constant temperature for 2 hours, then increase the temperature at a rate of 0.5°C ℃ / min to raise the temperature to 88°C and react at a constant te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com