Molybdenum disulfide and carbon nanotube composite material catalyst as well as preparation and application thereof

A technology of carbon nanotubes and molybdenum disulfide, which is applied in the field of electrocatalytic materials, can solve the problems of poor hydrogen evolution performance and achieve the effects of simple operation, strong controllability and wide source of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

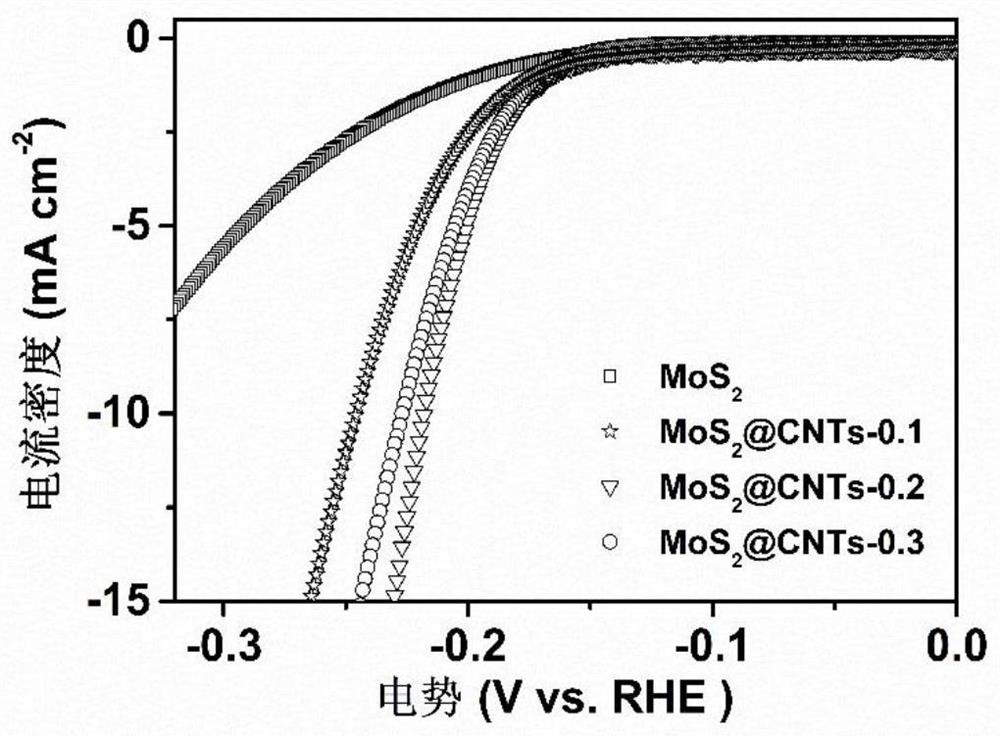

[0041] The invention relates to a preparation method and application of an electrocatalytic hydrogen evolution electrocatalyst with controllable interlayer spacing molybdenum disulfide / carbon nanotube, and belongs to the technical field of electrocatalytic material preparation. The method comprises the following steps: respectively dissolving organic sulfur source, molybdate and carbon nanotube in a solvent; mixing molybdenum salt and sulfur source and adding carbon nanotube solution to carry out hydrothermal reaction; centrifuging and separating with water and ethanol respectively Washing; drying to obtain solid powder; cooling to room temperature to obtain the product. The above catalyst is added to the sulfuric acid solution, and the electrocatalytic hydrogen evolution reaction is completed by using three electrodes as a working system.

[0042] details as follows:

[0043] S1. Mix 10-20mL deionized water and 10-20mL N,N-dimethylamide 1:2 as a solvent, mix 0.05-0.1g organi...

Embodiment 1

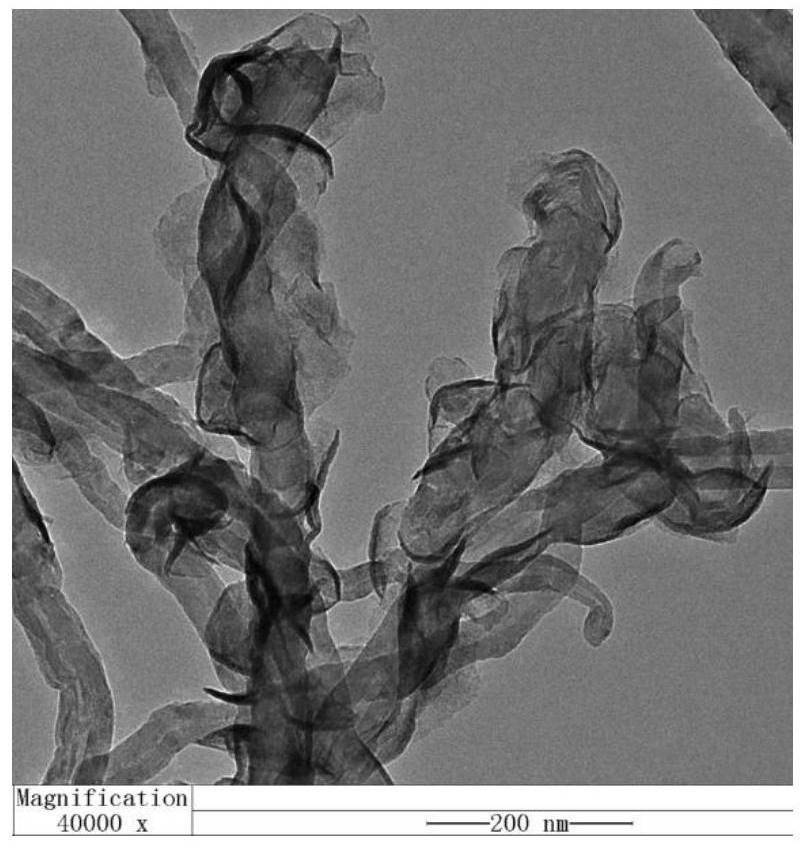

[0048] First, 0.2 g of carbon nanotubes were dispersed in a mixed solvent containing 5 mL of distilled water and 10 mL of N,N-dimethylamide solution. Next, dissolve 0.0846g of sodium molybdate in 5mL of distilled water and stir thoroughly for 30min until uniform. Then 0.1052g of dithiooxamide was uniformly dispersed in 10mL of N,N-dimethylamide solution. Finally, the three solutions were mixed, fully stirred for 30 minutes until uniform, and then loaded into a 1-2 MPa autoclave (the volume of the filled solution accounted for 60% of the volume of the autoclave lining during the reaction), and reacted at a constant temperature of 180°C for 24 hours. The product was cooled to room temperature for centrifugation, washed with water and ethanol solution for 6 times, and dried at 60°C to collect the powder. Get the final product MoS 2 / CNT.

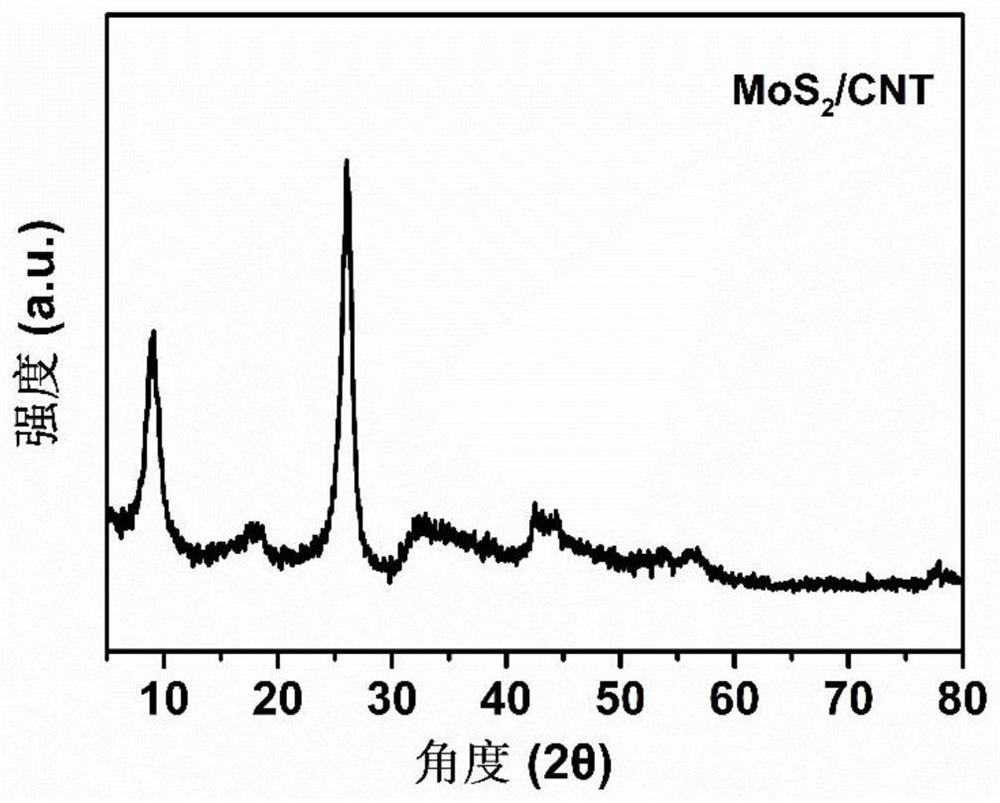

[0049] figure 1 is the MoS obtained in this example 2 / CNT electrocatalyst XRD diffraction pattern, compared with the PDF standard card, ...

Embodiment 2

[0052] Firstly, 0.3 g of carbon nanotubes were dispersed in a mixed solvent containing 5 mL of distilled water and 10 mL of N,N-dimethylamide solution. Next, dissolve 0.0846g of sodium molybdate in 5mL of distilled water and stir thoroughly for 30min until uniform. Then 0.1052g of dithiooxamide was uniformly dispersed in 10mL of N,N-dimethylamide solution. Finally, the three solutions were mixed, fully stirred for 30 minutes until uniform, and then loaded into a 1-2 MPa autoclave (the volume of the filled solution accounted for 60% of the volume of the autoclave lining during the reaction), and reacted at a constant temperature of 180°C for 24 hours. The product was cooled to room temperature for centrifugation, washed with water and ethanol solution for 6 times, and dried at 60°C to collect the powder. Get the final product MoS 2 / CNT.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com