Screen plate type glue-sealed blowback hollow fiber membrane assembly

A fiber membrane and flower board technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

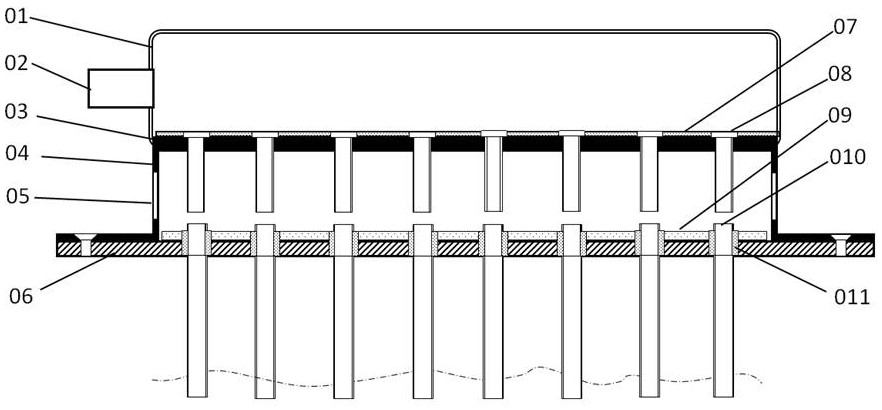

example 1

[0022] Example 1: The membrane thread (010) adopts the 4.5X3.5mm special hollow fiber membrane produced by Guangdong Fenghe Clean Engineering Co., Ltd. The thickness of the lower flower plate is 3mm, and the hole diameter is 4.5mm. The number of holes is 300. Insert the ends of 300 membrane wires (010) into the holes of the lower flower plate (06) with special tooling. Place the lower flower board horizontally, and add glue to protect the ring. Use cyanoacrylic instant glue as the membrane filament penetrating glue (011), and use a glue dispenser to evenly inject the glue. Because the viscosity of the cyanoacrylic instant glue is very low (30-50cps), it is easy to penetrate the membrane wall, and a single layer of glue can already fix the membrane and the hole of the lower flower plate. The flower plate type reverse blowing membrane module produced in this way can work stably at normal temperature.

example 2

[0023] Example 2: The membrane thread (010) adopts the 5X4mm special hollow fiber membrane produced by Guangdong Fenghe Clean Engineering Co., Ltd. The thickness of the lower flower plate is 3mm, and the hole diameter is 5mm. The number of holes is 300. Use special tooling to insert the ends of 300 membrane threads (010) into the plate holes of the lower flower plate (06), place the lower flower plate horizontally, and add glue to protect the ring. Use 30--400cps low-viscosity modified epoxy resin as the membrane thread penetration glue (011), heat the lower flower plate (06) and membrane silk penetration glue (011) to 50 degrees to reduce the viscosity, and use a dispenser to evenly Inject glue and cure at 100 degrees Celsius. Then use heat-cured modified epoxy resin with a viscosity of about 3000cps as the adhesive layer (09) of the lower flower plate, inject the glue evenly with a glue dispenser, and cure at 100 degrees Celsius. The flower plate-type glue-sealed reverse ...

example 3

[0024] Example 3: The membrane thread (010) adopts the 5X4mm special hollow fiber membrane produced by Guangdong Fenghe Clean Engineering Co., Ltd. The thickness of the lower flower plate is 3mm, and the hole diameter is 5mm. The number of holes is 300. Use special tooling to insert the ends of 300 membrane threads (010) into the plate holes of the lower flower plate (06), place the lower flower plate horizontally, and add glue to protect the ring. Use 30--400cps low-viscosity modified epoxy resin as the membrane thread penetration glue (011), heat the lower flower plate (06) and membrane silk penetration glue (011) to 50 degrees to reduce the viscosity, and use a dispenser to evenly Inject glue and cure at 100 degrees Celsius. The difference from Example 2 is that no high-viscosity glue is used for the second layer pouring. The flower plate-type glue-sealed reverse blowing membrane module produced in this way can also work reliably at a temperature below 210 degrees, and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com