Pressure sensor, preparation method and application thereof and intracranial pressure detection equipment

A technology of pressure sensors and elastic polymers, applied in the field of sensors, can solve the problems of poor flexibility, low sensitivity, hard texture, etc., and achieve the effects of flexible sensitivity, reduced cross-sectional area, and increased length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

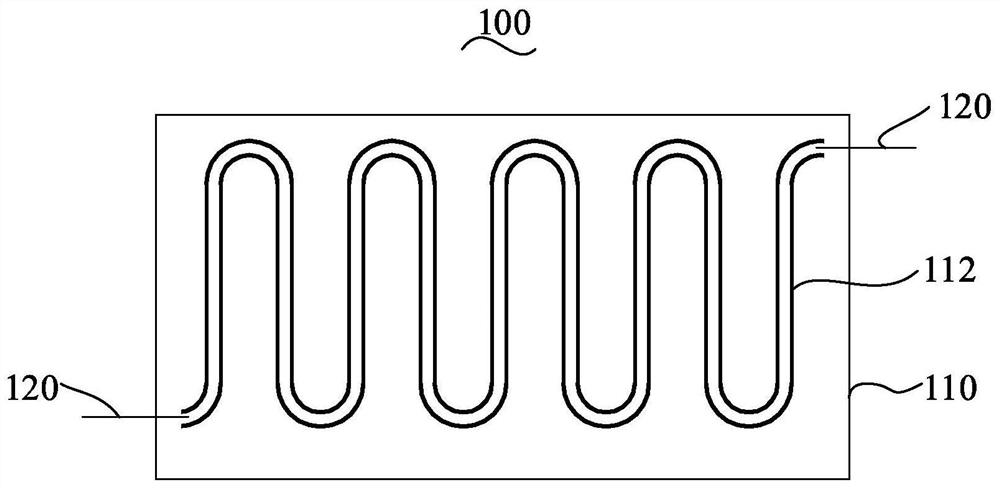

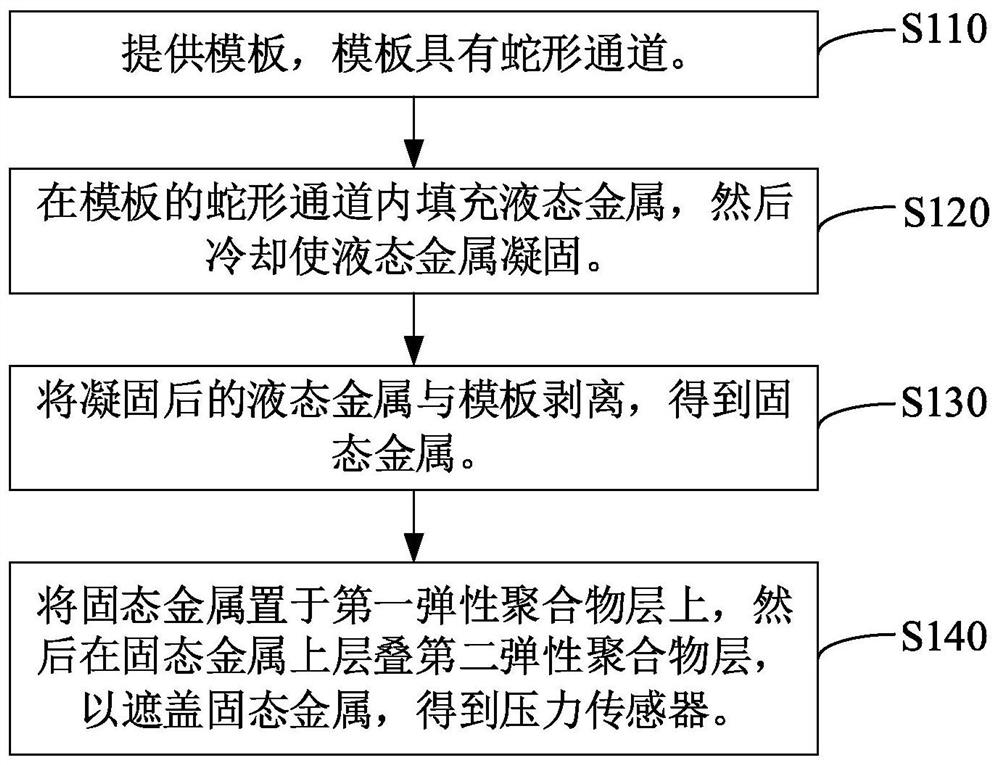

[0053] see figure 2 , the preparation method of the pressure sensor of an embodiment is a kind of preparation method of the above-mentioned pressure sensor, comprising the following steps:

[0054] Step S110: providing a template, the template has a serpentine channel.

[0055] Specifically, in one embodiment, the width of the serpentine channel is 1 μm˜1 cm, the height of the serpentine channel is 1 μm˜1 cm, and the length of the serpentine channel is 500 μm˜3 m.

[0056] Further, the width of the serpentine channel is 300 μm˜2000 μm, the height of the serpentine channel is 50 μm˜2000 μm, and the length of the serpentine channel is 200 mm˜2000 mm.

[0057] In this paper, the size of the serpentine channel can be adjusted according to actual needs.

[0058] Specifically, before step S110, a step of preparing a template is also included. In one of the embodiments, the step of preparing the template comprises:

[0059] The master template is printed by 3D printing, and the ...

Embodiment 1

[0098] The preparation process of the pressure sensor of embodiment 1 is specifically as follows:

[0099] (1) Use Soliworks software to design the structural graphics of the serpentine channel. The height (h) of the serpentine channel is 100 μm, the width is 500 μm, and the total length (L) is 455 mm; then the graphic file is converted into stl format, and then input to 3D printer (model EnvisionTEC), which converts graphics processing into graphics files that can be used by 3D printers; uses yellow resin material (HTM140 V2 (3D pixel is 25 μm ~ 50 μm)) to 3D print out the master template; weigh the appropriate weight of the precursor solution (model Dow Coming Sylgard 184, the precursor solution is composed of monomer and curing agent with a mass ratio of 10:1); pour the fully stirred precursor solution onto the 3D printed master template with a thickness of about 5mm, and put it in a vacuum drying dish Remove air bubbles for 15 minutes, then move to an oven at 80°C and ba...

Embodiment 2

[0105] The preparation process of the pressure sensor of embodiment 2 is specifically as follows:

[0106] (1) A serpentine channel is formed on the PDMS substrate by ion etching. The height (h) of the serpentine channel is 50 μm, the width is 300 μm, and the total length (L) is 200 mm to obtain a PDMS template.

[0107] (2) Seal the PDMS template with adhesive tape, and then open a small opening at one end of the serpentine channel to make it into a semi-sealed state. Use a syringe to inhale a certain amount of liquid metal gallium indium alloy, and fill the serpentine channel with liquid metal gallium indium alloy from one end with a small opening. Put the PDMS template filled with liquid metal gallium indium alloy into the refrigerator, and let it stand at -80°C for 20 minutes to make the liquid metal solidify.

[0108] (3) After the liquid gallium-indium alloy is solidified, take out the PDMS mold, tear off the sealing tape, and peel off the solid metal gallium-indium all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com