Kit for determining amino-terminal pro-brain natriuretic peptide, preparation method and detection method

A brain natriuretic peptide and amino-terminal technology, which is applied in the field of amino-terminal brain natriuretic peptide precursor assay kits, can solve problems such as low accuracy, human hazards, and poor reagent stability, so as to reduce batch-to-batch differences and maintain biological Activity, less impact on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

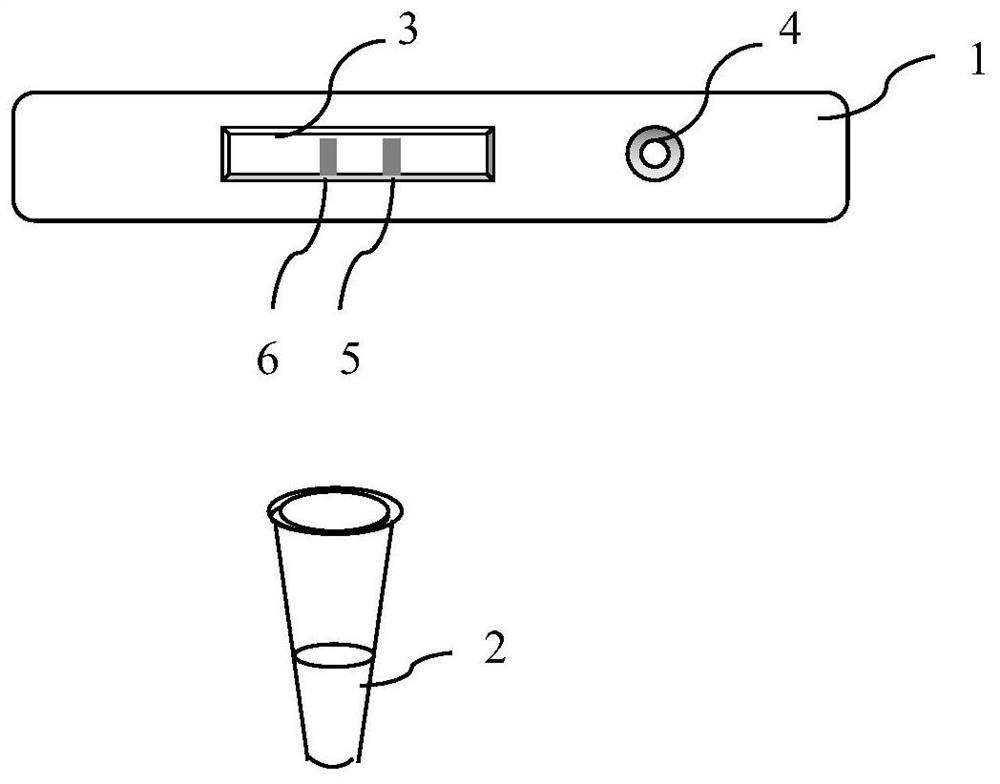

[0073] Preparation of reagent cards

[0074] (1) Preparation of detection line and quality control line: prepare amino-terminal brain natriuretic peptide precursor monoclonal antibody concentration of 2.0 mg / mL and goat anti-chicken IgY antibody concentration of 1 mg / mL respectively, and use a spray film machine to draw lines to On the test line and quality control line area on the nitrocellulose membrane, the coating volume is 1.0 μL / cm, put the scratched nitrocellulose membrane in a blast drying oven, and dry it at 50°C for 18 hours;

[0075] (2) Preparation of the sample pad: Prepare a blocking solution, add the blocking solution to the glass fiber to make the glass fiber completely wet, place it in a blast drying oven, and dry it at 50°C for 18 hours;

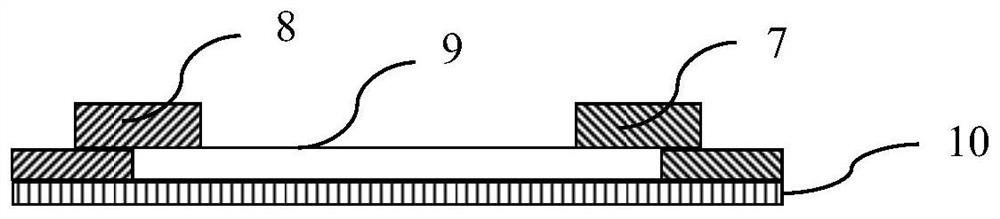

[0076] (3) Assembling of the reagent card: stick the nitrocellulose membrane to the backing plate, one end of the sample pad and one end of the water-absorbing pad are respectively lapped on the two ends of the nitrocellulo...

Embodiment 2

[0102] Preparation of reagent cards

[0103] (1) Preparation of test line and quality control line: prepare N-terminal BNP precursor monoclonal antibody concentration at 3.0 mg / mL and goat anti-rabbit IgG antibody concentration at 2 mg / mL respectively, and use a spray film machine to mark the line to On the test line and quality control line area on the nitrocellulose membrane, the coating volume is 0.8μL / cm, put the scratched nitrocellulose membrane in a blast drying oven, and dry it at 45°C for 20 hours;

[0104] (2) Preparation of the sample pad: Prepare a blocking solution, add the blocking solution to the glass fiber to make the glass fiber completely wet, place it in a blast drying oven, and dry it at 45°C for 20 hours;

[0105] (3) Assembling of the reagent card: stick the nitrocellulose membrane to the backing plate, one end of the sample pad and one end of the water-absorbing pad are respectively lapped on the two ends of the nitrocellulose membrane, cut into test str...

Embodiment 3

[0128] Preparation of reagent cards

[0129] (1) Preparation of test line and quality control line: Prepare N-terminal BNP precursor monoclonal antibody concentration at 0.5 mg / mL and goat anti-mouse IgG antibody concentration at 0.5 mg / mL respectively, and use a spray film machine to draw the line To the test line and quality control line area on the nitrocellulose membrane, the coating volume is 0.5 μL / cm, put the scratched nitrocellulose membrane in a blast drying oven, and dry it at 37°C for 24 hours;

[0130] (2) Preparation of the sample pad: Prepare a blocking solution, add the blocking solution to the glass fiber to make the glass fiber completely wet, place it in a blast drying oven, and dry it at 37°C for 24 hours;

[0131] (3) Assembling of the reagent card: stick the nitrocellulose membrane to the backing plate, one end of the sample pad and one end of the water-absorbing pad are respectively lapped on the two ends of the nitrocellulose membrane, cut into test stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com