Magnetic control sucker device and using method thereof

A suction cup and magnetic control technology, applied in the direction of magnets, suction cups, permanent magnets, etc., can solve problems such as use, unfavorable medical fields, and inability to be easily removed, and achieve the effects of simple device structure, expanded use range, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] More specifically, the preparation method of the hard magnetic floppy disk comprises the following steps:

[0055] a) Take two-component silica gel and hard magnetic particles and mix them to obtain a mixed solution;

[0056] b) Pour the above mixed solution into a circular petri dish, then place the round petri dish in a vacuum drying oven, vacuumize it, and let it stand to obtain a hard magnetic floppy disk after curing;

[0057] c) Magnetizing the hard-magnetic floppy disk, applying a high-intensity parallel magnetic field along the thickness direction of the hard-magnetic floppy disk to obtain a magnetized hard-magnetic floppy disk.

[0058] Further, in step a), the mixing is stirring in a mixer, the stirring speed is 600-700rpm, and the stirring time is 5 minutes;

[0059] In step b), the vacuuming time is 5 to 20 minutes, and the standing time is 1 to 6 hours;

[0060] In step c), the intensity of the magnetic field is 1-2T, and the magnetization time is 5-10 mi...

Embodiment 1

[0072] Example 1 A method of using a magnetically controlled chuck for adsorption

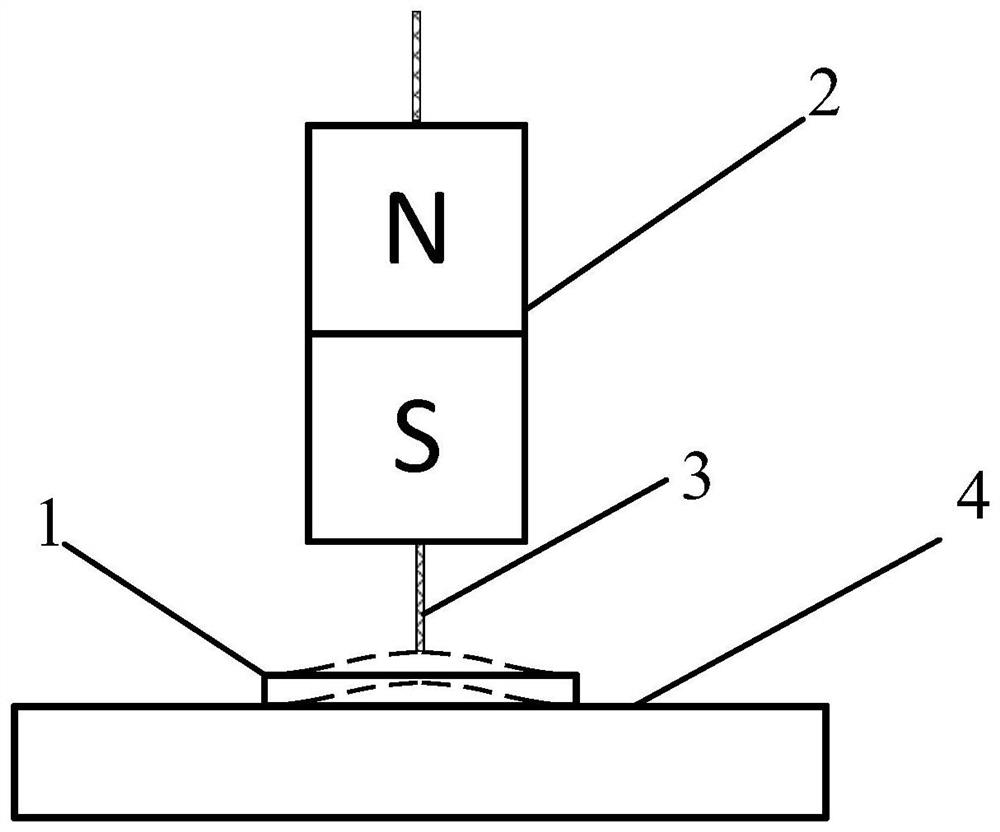

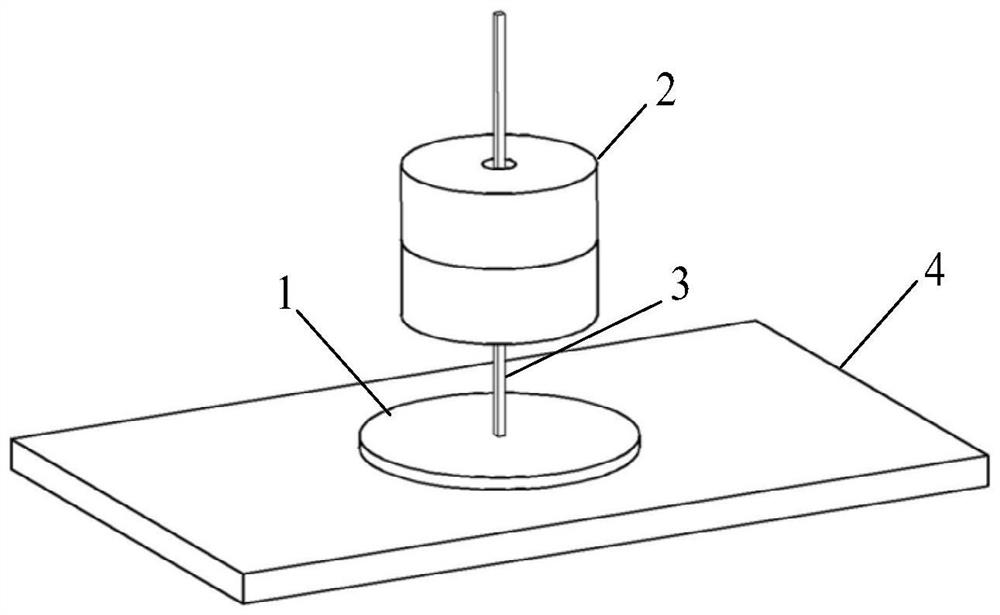

[0073] The magnetically controlled chuck comprises: a disc-shaped hard magnetic floppy disk, a cylindrical magnet (NdFeB permanent magnet), and a rope, wherein the hard magnetic floppy disk 1, the magnet piece, and the rope are coaxially arranged.

[0074] Specific adsorption methods include:

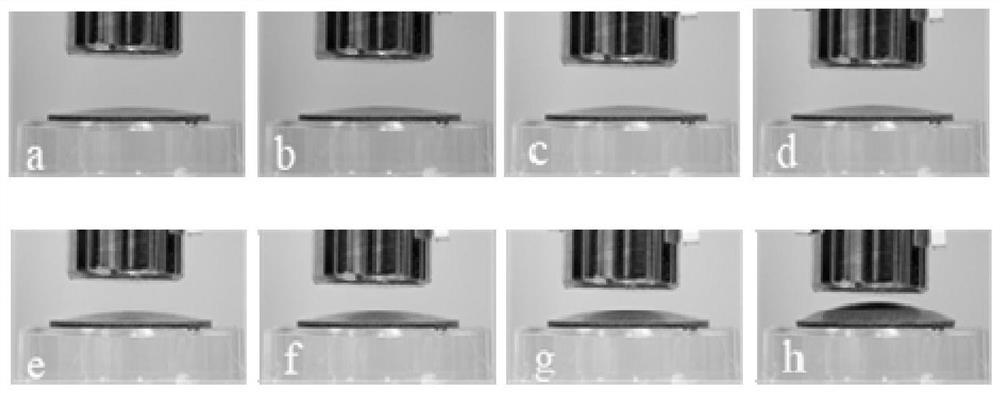

[0075] The magnet and the hard magnetic floppy disk are approached in the same way with the same magnetic poles, and the distance between the magnet and the hard magnetic floppy disk is adjusted to 22mm to control the adsorption strength of the hard magnetic floppy disk to the adsorbed substance, so as to realize the hard magnetic floppy disk for the adsorbed substance. adsorption;

[0076] When the hard magnetic floppy disk needs to be desorbed from the substance to be adsorbed, the rope is pulled to realize desorption.

Embodiment 2~8

[0078] Same as embodiment 1, the difference is that the distances between the magnet parts and the hard magnetic floppy disk are 20mm, 18mm, 16mm, 14mm, 12mm, 10mm, 8mm respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com