Zeolite molecular sieve with multi-stage pore structure and preparation method and application of zeolite molecular sieve

A technology of zeolite molecular sieve and pore structure, applied in molecular sieves and base exchange compounds, molecular sieve catalysts, crystalline aluminosilicate zeolites, etc., can solve the problem of reducing the wear resistance of catalysts in fluidized beds, destroying the crystallinity and strength of molecular sieves, Time-consuming and labor-intensive problems, to achieve the effects of rich pore structure, improved anti-carbon deposition ability, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

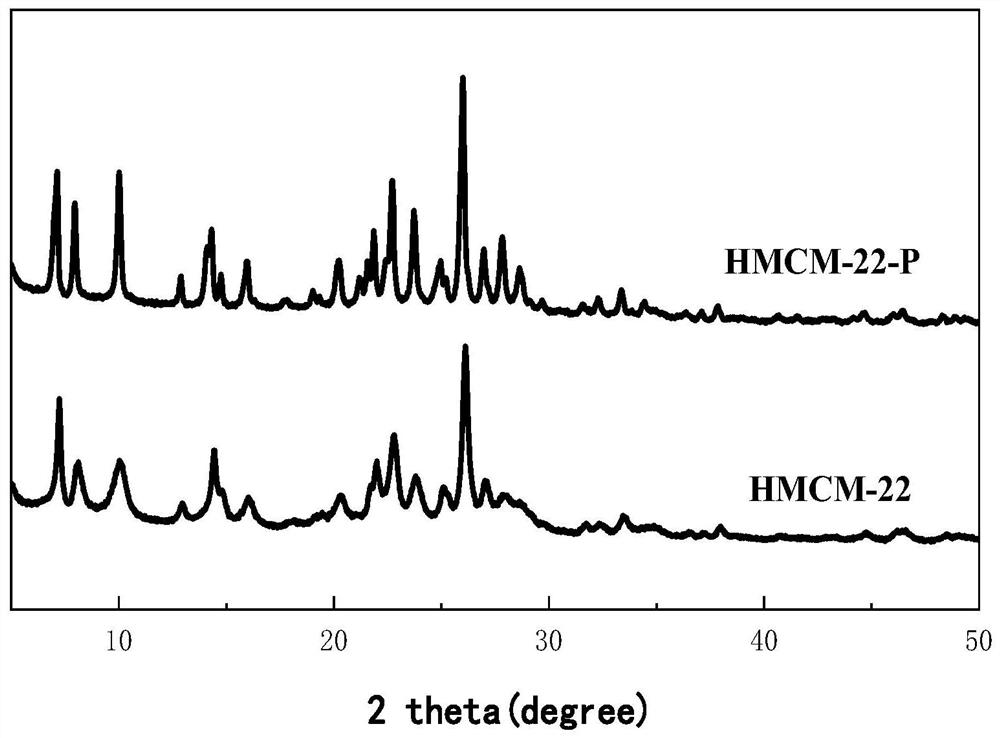

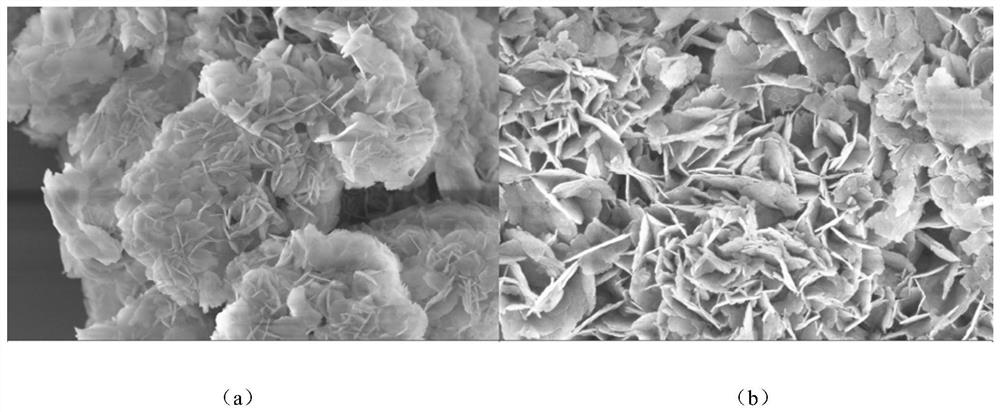

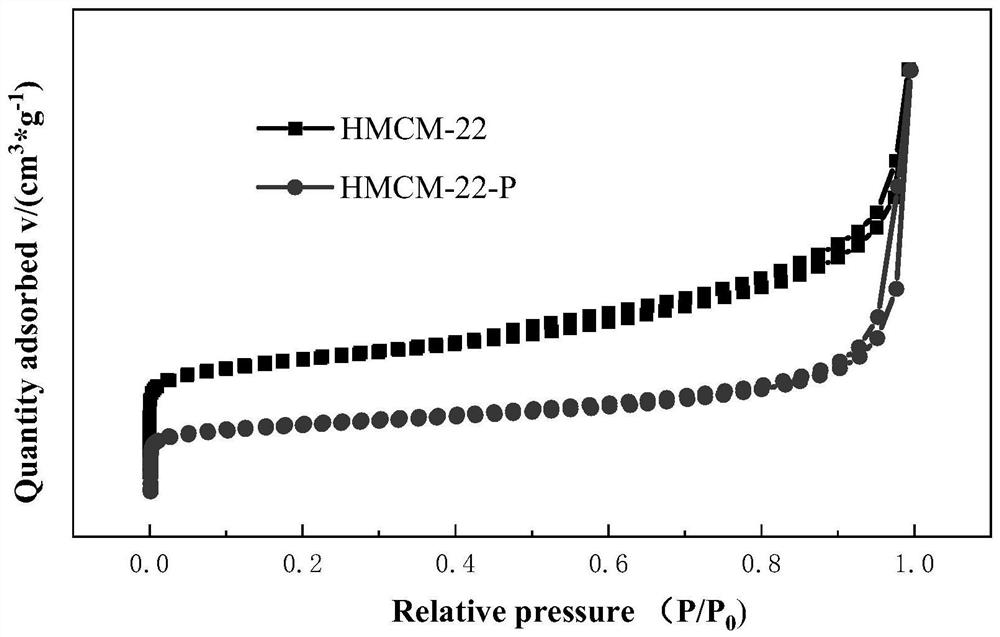

Embodiment 1

[0053] Take a clean 100ml beaker, add 47.96ml of deionized water and 1g of PDDA, place in a water bath at 30°C and stir for 3 hours. Accurately weigh 0.4896g of sodium aluminate and 0.2025g of sodium hydroxide, pour into a beaker, mix and stir until the solution is clear. Add 4.5ml of hexamethyleneimine at a rate of 1 drop per second, and mix and stir for 30 minutes. Add 24.848g of silica sol at a rate of 2 drops per second, and stir vigorously for 30 minutes. Pour the above mixture into a polytetrafluoroethylene-lined hydrothermal kettle, and place it in a rotary oven for dynamic crystallization at a rotation rate of 60r / min. First crystallized at 50℃ for 2h, then heated to 140℃ for 5d. After the crystallization, wash and centrifuge and dry, and then place it in a muffle furnace and bake at 550°C for 10 hours to obtain Na-MCM-22. Mix Na-MCM-22 and 1mol / L ammonium nitrate solution with 80 at a ratio of 1:30 °C ammonium exchange in a water bath for 3 times, and then calcined ...

Embodiment 2

[0055] Take a clean 100ml beaker, add 47.96ml of deionized water and 1.5g of PDDA, place in a water bath at 30°C and stir for 3 hours. Accurately weigh 0.4896g of sodium aluminate and 0.2025g of sodium hydroxide, pour into a beaker, mix and stir until the solution is clear. Add 4.5ml of hexamethyleneimine at a rate of 1 drop per second, and mix and stir for 30 minutes. Add 24.848g of silica sol at a rate of 2 drops per second, and stir vigorously for 30 minutes. Pour the above mixture into a polytetrafluoroethylene-lined hydrothermal kettle, and place it in a rotary oven for dynamic crystallization at a rotation rate of 60r / min. The crystallization is carried out step by step. Firstly, it is crystallized at 50°C for 4h, and then it is heated to 140°C for 5d. After the crystallization is completed, it is washed and centrifuged and dried, and then placed in a muffle furnace and roasted at 550°C for 10h to obtain Na-MCM-22. Na-MCM-22 and 1 mol / L ammonium nitrate solution were ex...

Embodiment 3

[0057] Take a clean 100ml beaker, add 47.96ml of deionized water and 2.5g of PDDA, place in a water bath at 30°C and stir for 3 hours. Accurately weigh 0.4896g of sodium aluminate and 0.2025g of sodium hydroxide, pour into a beaker, mix and stir until the solution is clear. Add 4.5ml of hexamethyleneimine at a rate of 1 drop per second, and mix and stir for 30 minutes. Add 24.848g of silica sol at a rate of 2 drops per second, and stir vigorously for 30 minutes. Pour the above mixture into a polytetrafluoroethylene-lined hydrothermal kettle, and place it in a rotary oven for dynamic crystallization at a rotation rate of 60r / min. The crystallization is carried out step by step. Firstly, it is crystallized at 50°C for 6h, and then it is heated to 140°C for 5d. After the crystallization is completed, it is washed and centrifuged and dried, and then placed in a muffle furnace and roasted at 550°C for 10h to obtain Na-MCM-22. Na-MCM-22 and 1 mol / L ammonium nitrate solution were ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com