Fluorocarbon paint anticorrosive coatings inside and outside heating radiator and production equipment

A technology of internal fluorocarbon paint and anti-corrosion coating, which is applied in the field of fluorocarbon paint anti-corrosion coating inside and outside radiators and production equipment, which can solve problems such as cracking and extruder blockage, and achieve the effect of strong crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: a kind of radiator internal and external fluorocarbon paint anticorrosion coating, it comprises fluorocarbon resin, fiber silk, defoamer, dispersant, plasticizer, water-repellent agent, and above-mentioned each component counts parts by weight respectively It is: 30 parts of fluorocarbon resin, 0.8 parts of fiber, 2 parts of defoamer, 1 part of dispersant, 2 parts of plasticizer, 1 part of hydrophobic agent, the length of fiber is 2-10mm, and the fluorocarbon resin is broken into 50-90 mesh.

[0024] Preferably, it also includes silver ions, and the silver ions are 2 parts by weight.

Embodiment 2

[0025] Embodiment 2: a kind of radiator internal and external fluorocarbon paint anticorrosion coating, it comprises fluorocarbon resin, fiber filament, defoamer, dispersant, plasticizer, water-repellent agent, and above-mentioned each component counts parts by weight respectively It is: 40 parts of fluorocarbon resin, 2 parts of fiber filament, 5 parts of defoamer, 2 parts of dispersant, 5 parts of plasticizer, 2 parts of hydrophobic agent, the length of fiber filament is 2-10mm, and the fluorocarbon resin is broken into 50-90 mesh.

[0026] Preferably, it also includes silver ions, and the silver ions are 5 parts by weight.

Embodiment 3

[0027] Embodiment 3: a kind of radiator internal and external fluorocarbon paint anticorrosion coating, it comprises fluorocarbon resin, fiber silk, defoamer, dispersant, plasticizer, water-repellent agent, and above-mentioned each component counts parts by weight respectively It is: 35 parts of fluorocarbon resin, 1.2 parts of fiber filament, 3 parts of defoamer, 1.5 parts of dispersant, 3 parts of plasticizer, 1.5 parts of hydrophobic agent, the length of fiber filament is 2-10mm, and the fluorocarbon resin is broken into 50-90 mesh.

[0028] Preferably, it also includes silver ions, and the silver ions are 3 parts by weight.

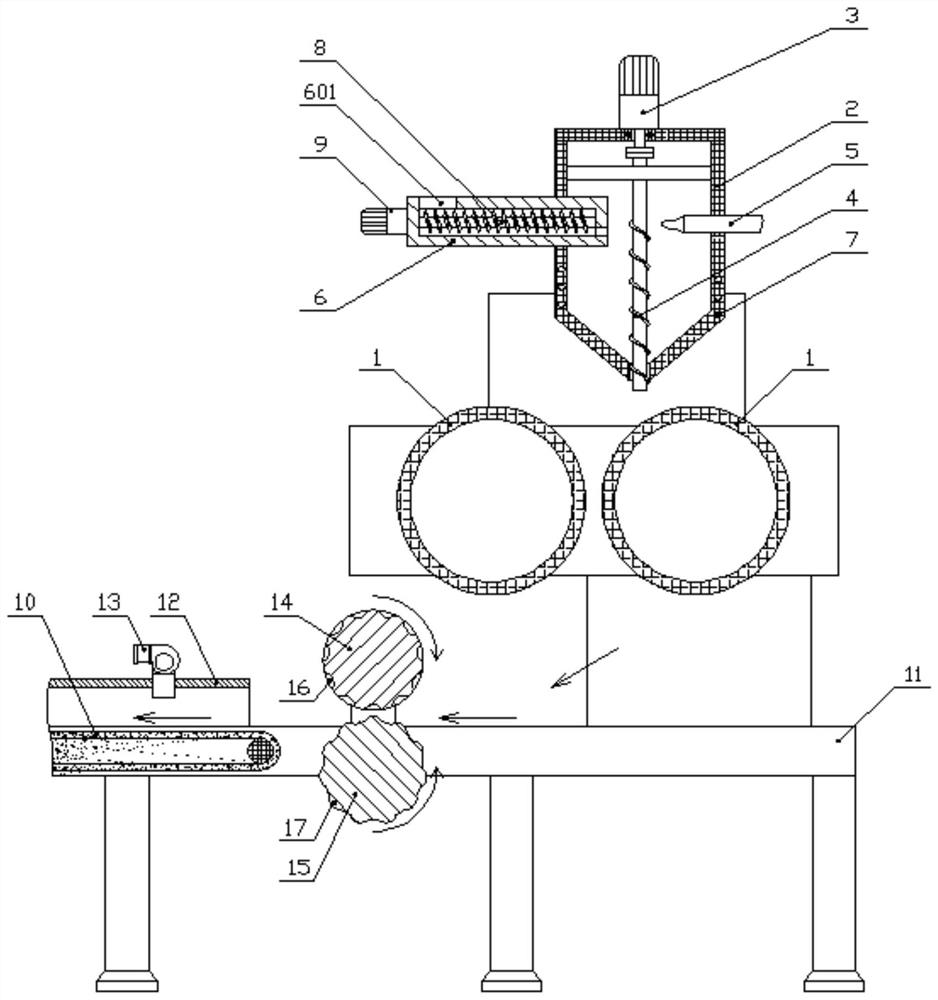

[0029] Such as figure 1 As shown, the specific structure of a production equipment for the internal and external fluorocarbon paint anti-corrosion coating of radiators is as follows: it includes two extrusion rollers 1 arranged at horizontal intervals, the extrusion rollers 1 are movably arranged on the bracket, and the two extrusion rollers Roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com