Inorganic high-strength filler for coating

An inorganic, high-strength technology, used in filling slurry, sustainable waste treatment, solid waste management, etc., can solve the problems of low strength, easy pulverization, and high brittleness, and achieve high impermeability strength, good weather resistance, strong The effect of crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0011] Example 1, YT110:

[0012] White cement

[0013] Add the above-mentioned raw materials into the mixer according to the above-mentioned mixing ratio, stir well, and then pack it to get YT110 easy-to-coat powder. Mix the easy-to-coat powder and water at a ratio of 1:0.21 to form a paste, which can be used as putty for the coating system of ordinary walls. Layer, floor paint putty layer and other construction.

example 2

[0014] Example 2, YT210:

[0015] White cement

[0016] Add the above-mentioned raw materials into the mixer according to the above-mentioned mixing ratio, mix them well, and then pack them to get YT210 easy-to-coat powder. Mix the easy-to-coat powder and water at a ratio of 1:0.21 to form a paste, which can be used for aerated concrete wall coating. Construction of system anti-crack plastering mortar, roof anti-crack waterproof paint coating system putty, etc.

example 3

[0017] Example 3, YT310:

[0018] White cement

Quartz sand

Quartz powder

wollastonite powder

rubber powder

Polypropylene fibers

275

350

246.7

100

22

5

1.3

[0019] Add the above-mentioned raw materials into the mixer according to the above-mentioned mixing ratio, mix them well, and then pack them to get YT310 easy-to-coat powder. Mix the easy-to-coat powder with water at a ratio of 1:0.21 and stir to form a paste, which can be used in the external wall thermal insulation coating system for anti-corrosion. Construction of crack plastering mortar, etc.

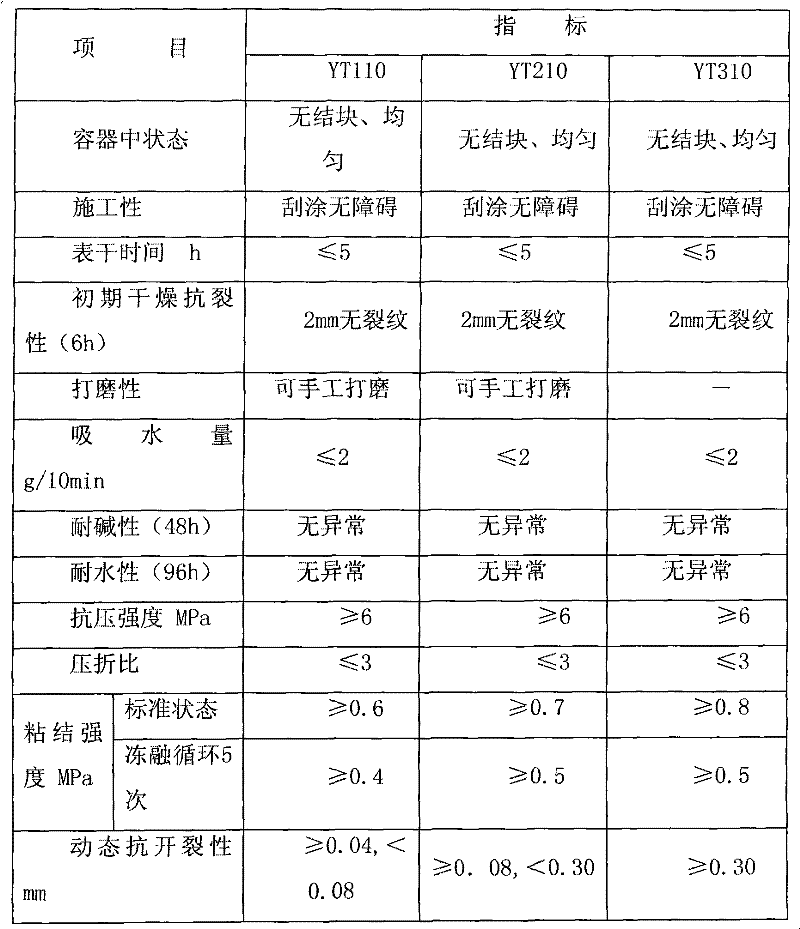

[0020] The performance indicators are as follows:

[0021]

[0022] The product of the invention can be easily applied and scraped on dry walls (including various brick walls, concrete layers, ordinary mortar surfaces and insulation layers of thermal insulation systems), and is simple and convenient in construction, easy in leveling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com