A new type of water transfer printing coating film

A technology of water transfer printing and coating film, which is applied in the field of new water transfer printing coating film, which can solve the problems that affect the coating quality of the product surface, the pattern is easy to wear or fall off, and the spraying effect is not good, so as to ensure the coating effect , good wear resistance, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

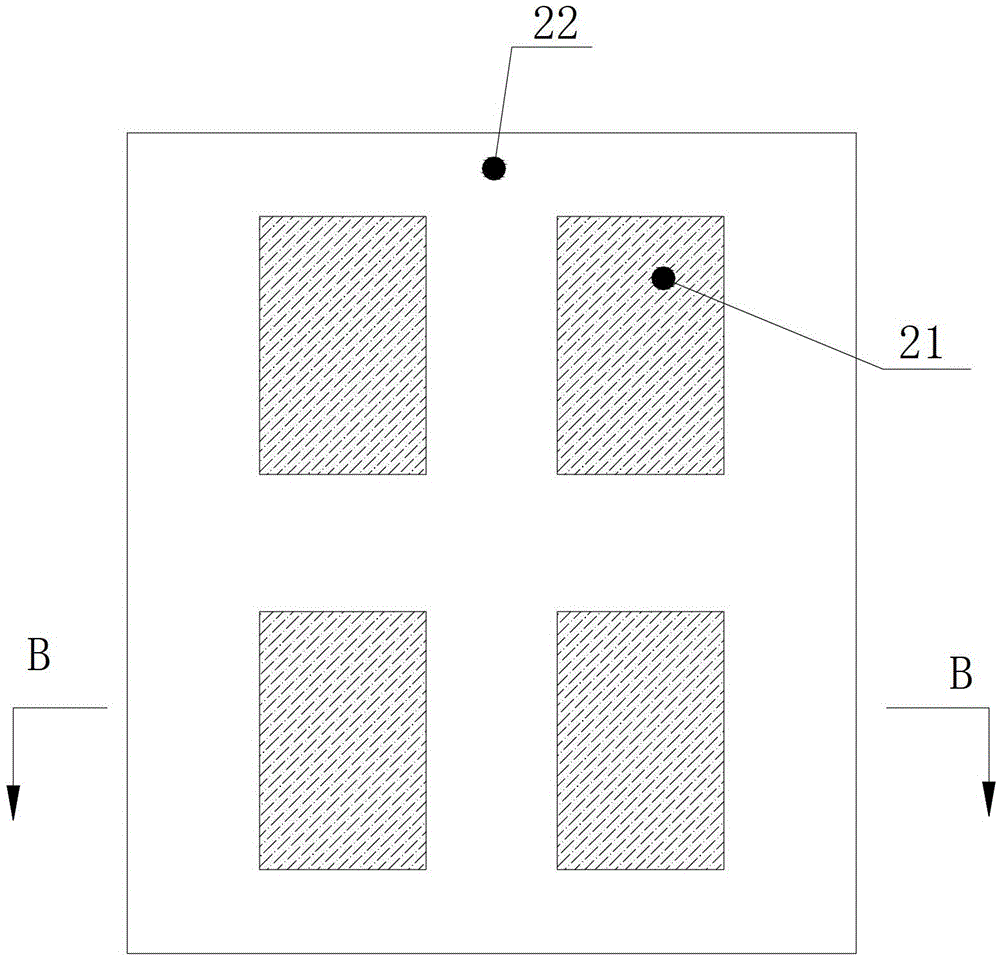

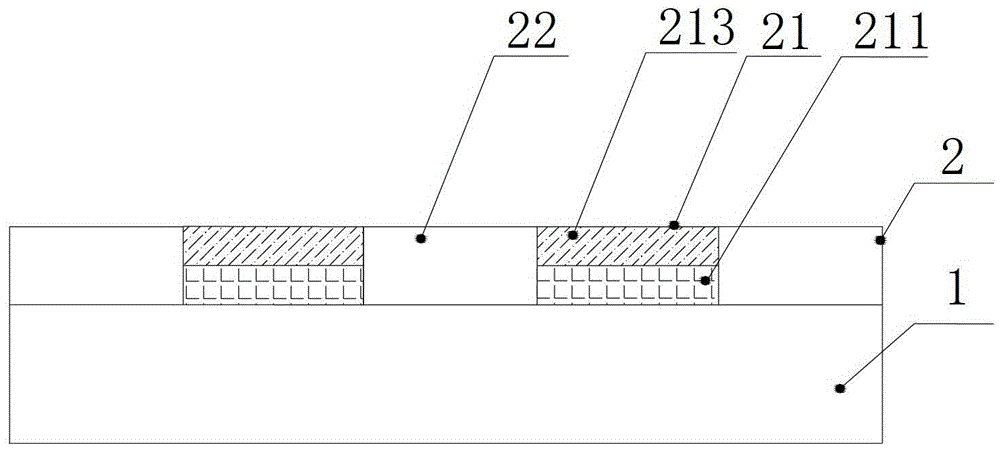

[0039] Such as figure 1 with image 3 As shown, the water transfer coating film of this embodiment includes a water-soluble film layer 1 and a coating layer 2. The water-soluble film layer 1 is made of water-based PET film, and the coating layer 2 includes a plurality of pattern areas 21 and a coating area 22. . A plurality of pattern areas 21 are spaced from each other, and the paint area 22 is connected to the pattern area 21 and is arranged around the pattern area 21. The paint area 22 is selected from the water-based paint PVA coating; the pattern area 21 includes the first functional coating 211 and ink coating 213. The first functional coating 211 is formed by coating with UV photocurable coating.

[0040] The manufacturing method of the water transfer printing coating film is:

[0041] (1) The water-based PET film is purchased from the market, and a PET film with a film thickness of 80 μm is selected as the water-soluble film layer 1;

[0042] (2) To make the coatin...

Embodiment 2

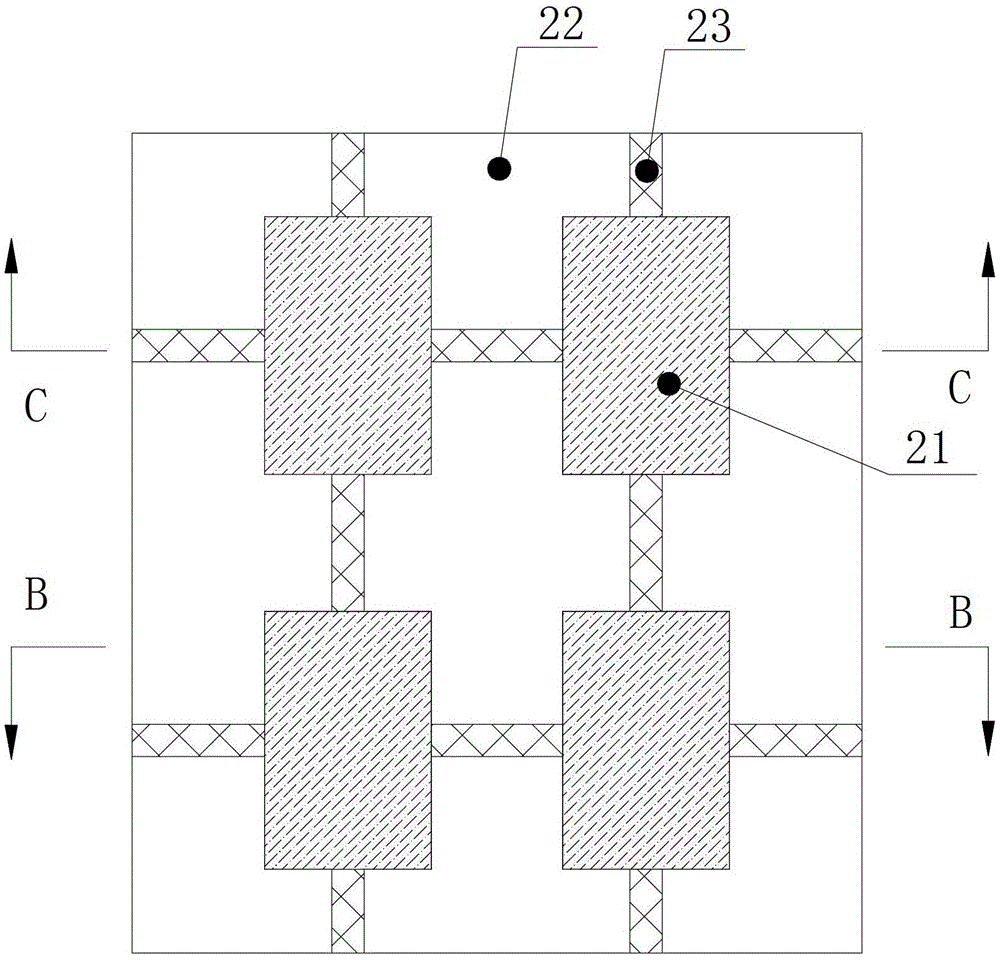

[0053] Such as figure 2 , 3 , 5, the water-transfer coating film of the present embodiment comprises a water-soluble film layer 1 and a coating layer 2, and the water-soluble film layer 1 is selected from a PVA film, and the coating layer 2 is composed of a plurality of pattern areas 21, a plurality of coatings A region 22 and a plurality of PVA regions 23 are formed. A plurality of paint areas 22 are spaced from each other and are arranged around each pattern area 21. Each PVA area 23 is connected to the pattern area 21 and separates the two paint areas 22. The paint area 22 is selected from non-aqueous paint PU paint. The pattern area 21 includes a first functional coating 211 and an ink coating 213. The first functional coating 211 is coated with a coating made of UV photocurable coating doped with nanomaterials.

[0054] The manufacturing method of the water transfer printing coating film is:

[0055] (1) The PVA film is purchased from the market, and a PET film with a...

Embodiment 3

[0068] Such as figure 2 , 4 , 6, the water transfer coating film of the present embodiment comprises a water-soluble film layer 1, a coating layer 2, and the water-soluble film layer 1 selects a water-based PVC film, and the coating layer 2 consists of a plurality of pattern areas 21, a plurality of The paint area 22 and a plurality of PVA areas 23 are constituted. A plurality of paint areas 22 are spaced from each other and are arranged around each pattern area 21. Each PVA area 23 is connected to the pattern area 21 and separates the two paint areas 22. The paint area 22 is selected from non-aqueous paint PE paint The pattern area 21 comprises the first functional coating 211, the second functional coating 212 and the ink coating 213, the first functional coating 211 is coated with nano-coating for use, and the second functional coating 212 is selected for use Made of PU coating.

[0069] The manufacturing method of the water transfer printing coating film is:

[0070] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com