A gearbox assembly method and assembly system

An assembly system and assembly method technology, applied in assembly machines, transmission parts, metal processing equipment, etc., can solve the problems of high assembly requirements, complex assembly process, low assembly accuracy, etc., to optimize assembly process, control product quality, The effect of saving assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

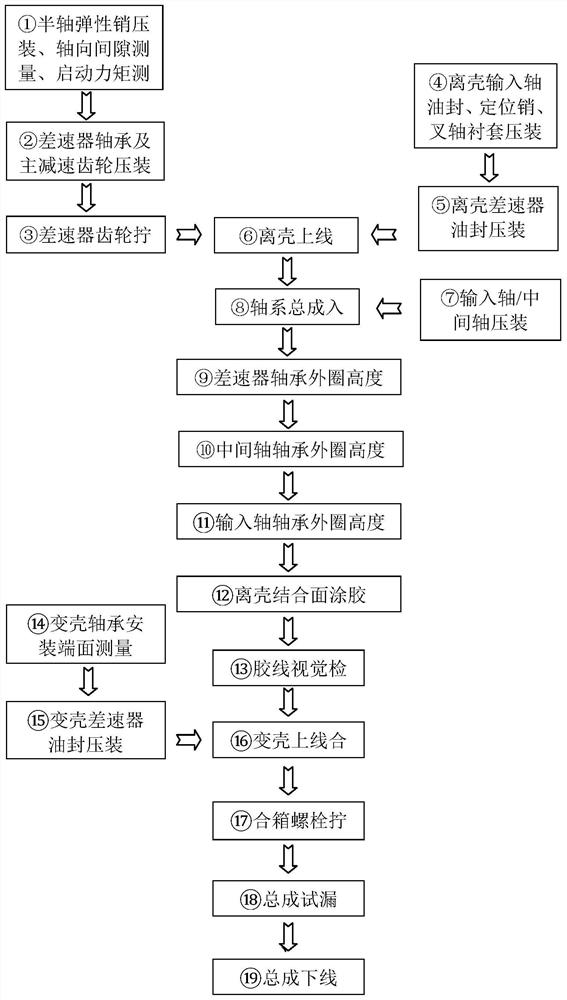

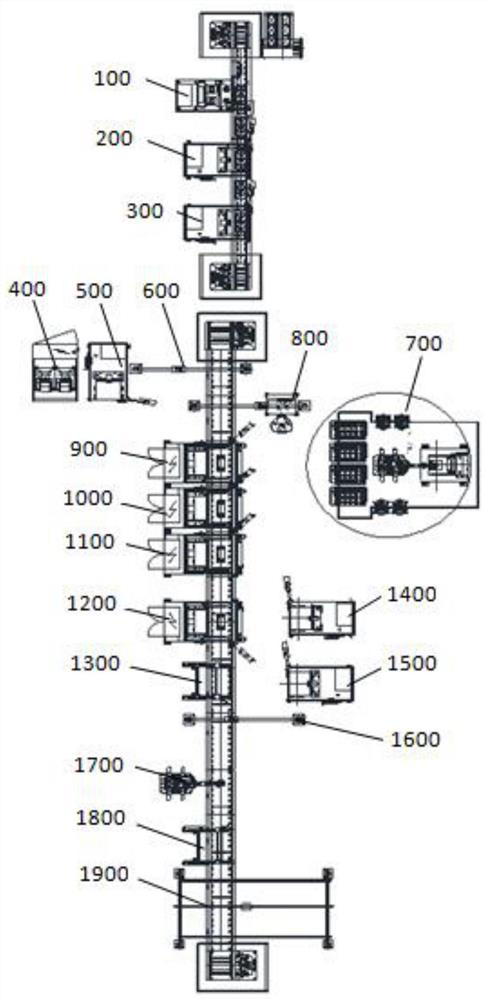

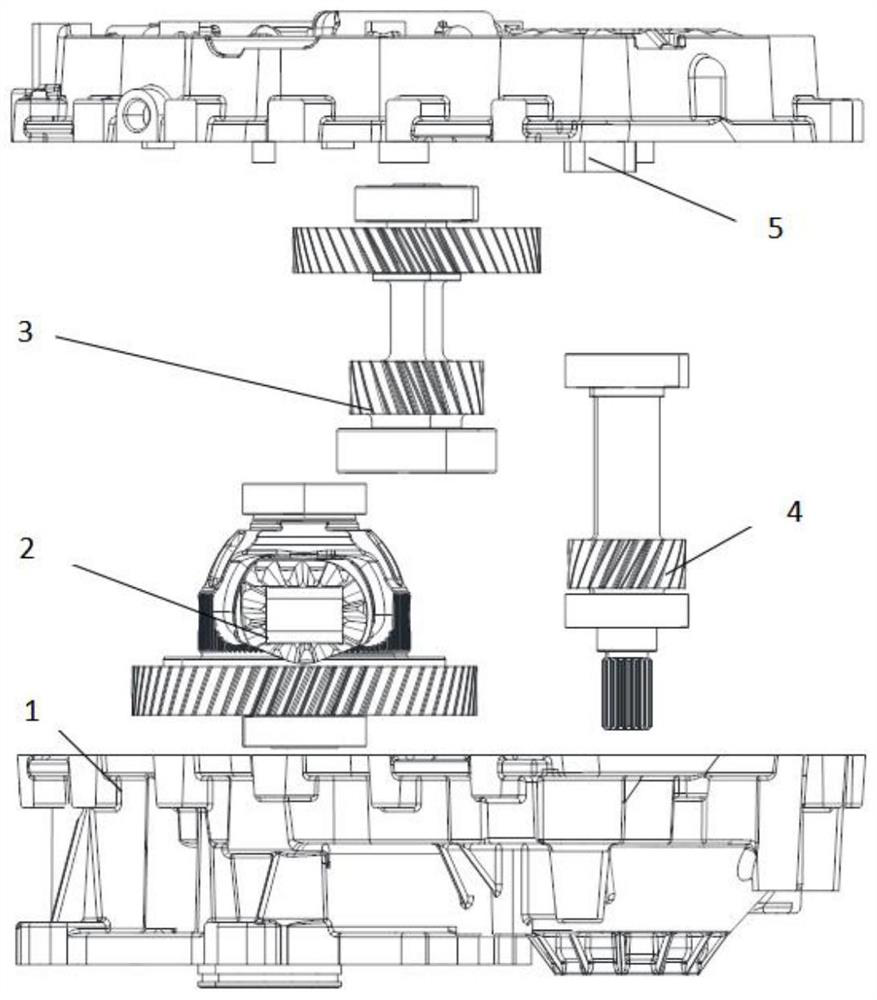

[0024] Such as image 3 As shown, the gearbox includes a differential 1, a casing 2, an input shaft assembly 3, an intermediate shaft assembly 4, and a variable casing 5, such as figure 2 As shown, the assembly system of the gearbox includes the assembly assembly line, the differential assembly line, the shell separation line, the input shaft / intermediate shaft assembly line and the variable shell assembly line, the differential assembly line, the shell separation line Sub-assembly line, input shaft / intermediate shaft sub-assembly line, variable case sub-assembly line are used to produce differential 1, separation case 2, input shaft assembly 3, intermediate shaft assembly 4, variable case 5, and the assembly assembly line will be differential The gearbox 1, the off-case 2, the input shaft assembly 3, the intermediate shaft assembly 4, and the variable case 5 are assembled into a finished gearbox. The assembly assembly line includes the off-shell on-line equipment 600, the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com