Water-resistant epoxy sealant based on low cost

A water-resistant, low-cost technology, used in epoxy resin adhesives, adhesives, adhesive types, etc., can solve the problems of high labor intensity and low efficiency, achieve a high degree of automation, reasonable process settings, and realize intelligent automatic production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

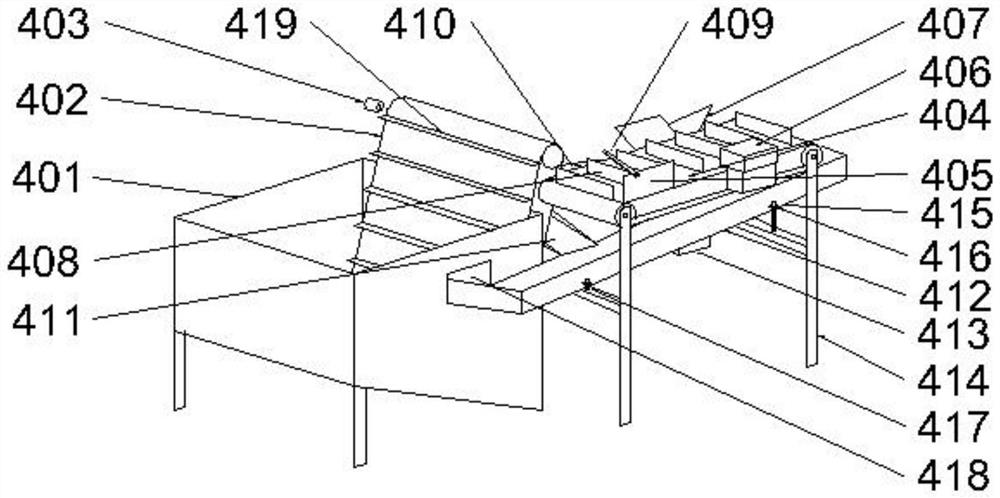

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with all the accompanying drawings, and the preferred embodiment of the present invention is: figure 1 , the low-cost water-resistant epoxy resin joint agent described in this embodiment includes A component and B component;

[0027] The A component includes the following raw materials in parts by mass: 90-95 parts of epoxy resin, 8-12 parts of diluent, 0.01-0.03 parts of defoamer, and 3-9 parts of thixotropic agent;

[0028] The B component includes the following raw materials in parts by mass: 10-16 parts of modified alicyclic amine curing agent, 15-20 parts of aliphatic amine, 35-42 parts of diluent, 0.01-0.03 part of defoamer, thixotropic agent 3-8 parts, 1-3 parts of dispersant, 2-5 parts of accelerator;

[0029] The point mass ratio of the A component to the B component is 1:1-1.16.

[0030] The preparation method of described modified alicyclic amine comprises:

[0031] Control the degree of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com