A separation device and method for removing impurities in waste lubricating oil

A waste lubricating oil and separation device technology, applied in the direction of lubricating compositions, etc., can solve the problems of low impurities, complicated separation process, and the regeneration recovery rate needs to be improved, so as to promote neutralization reaction, increase regeneration recovery rate, and reduce water cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

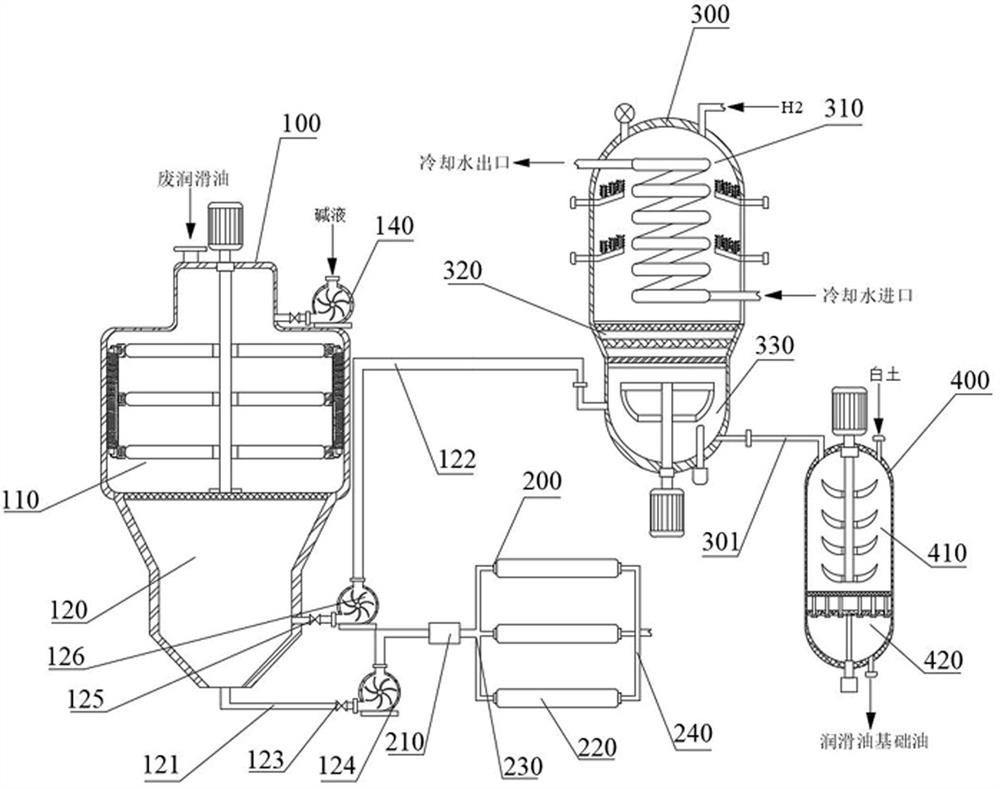

[0042] Such as Figure 1-2 As shown, this embodiment provides a separation device for removing impurities in waste lubricating oil, which is equipped with alkali neutralization, sedimentation, water phase infiltration and impurity removal for waste lubricating oil, removal of metal impurities and asphaltenes, hydrofining, steam It has the functions of distillation, decolorization and refining, and can obtain high-purity, low-impurity lubricating base oil after treatment. Specifically, the separation device for removing impurities in waste lubricating oil includes an alkali neutralization settling tank 100, a reverse osmosis membrane module 200, a hydrofinishing distillation tank 300, and a decolorization refining tank 400. And chamber 110 and the settling chamber 120 below, filter plate 130 is provided between alkali neutralization chamber 110 and settling chamber 120, is filled with particle diameter 20~60 mesh quartz sands in the filter plate 130; There is a waste lubricati...

Embodiment 2

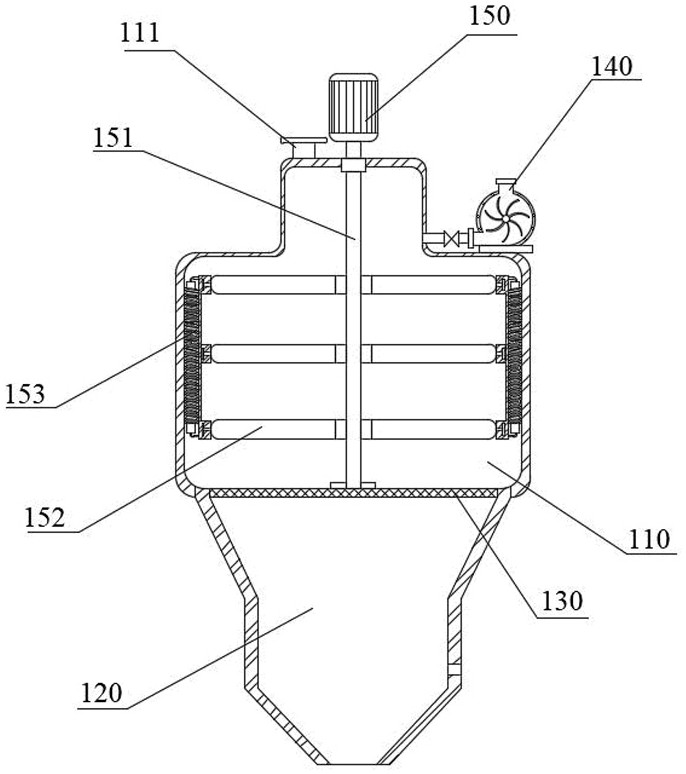

[0046] Such as Figure 1-3 As shown, the present embodiment is a separation device for removing impurities in waste lubricating oil. A stirring and mixing mechanism is provided in the alkali neutralization chamber 110. The stirring and mixing mechanism includes a first reduction motor 150, a first stirring shaft 151, a stirring plate 152, an anti-sticking Attached mechanism 153, the first decelerating motor 150 penetrates from the top of the alkali neutralization chamber 110 and is coaxially connected with the first stirring shaft 151, the first stirring shaft 151 extends to the bottom of the alkali neutralization chamber 110, and a plurality of stirring plates 152 Symmetrically arranged in the radial direction of the first stirring shaft 151 , the anti-adhesion mechanism 153 is arranged at the ends of the plurality of stirring plates 152 and is in contact with the inner wall of the alkali neutralization chamber 110 .

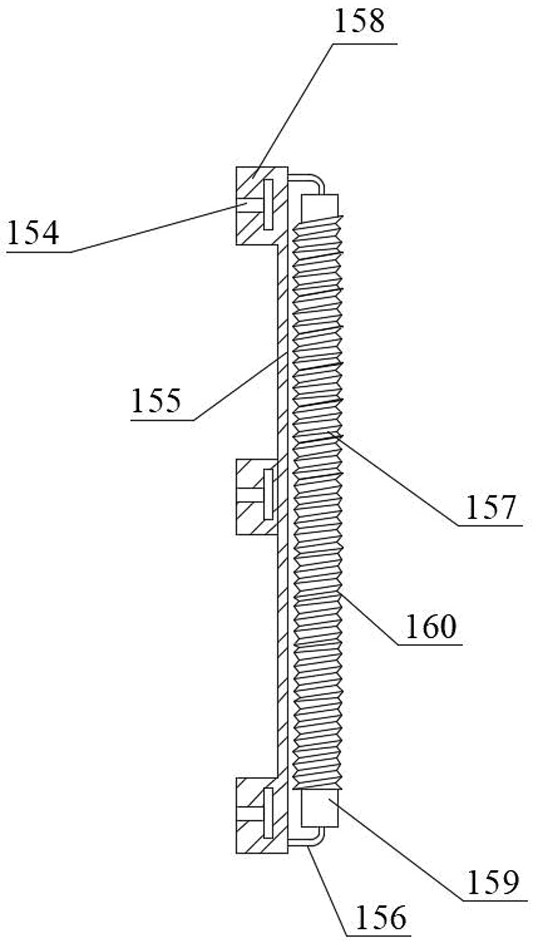

[0047] The main body of the stirring plate 152 is cylindr...

Embodiment 3

[0051] Such as figure 1 , Figure 4-5 As shown, the present embodiment is a separation device for removing impurities in waste lubricating oil. The hydrofining distillation tank 300 includes a hydrodistillation chamber 310, an adsorption chamber 320, a heating and vaporization chamber 330, and a hydrodistillation chamber arranged in sequence from top to bottom. 310 is provided with a condensing pipe 311, the bottom end of the condensing pipe 311 is provided with a cooling water inlet 312 that runs through the wall of the hydrodistillation chamber 310, and the top of the condensing pipe 311 is provided with a cooling water outlet 313 that runs through the hydrodistillation chamber 310. Both sides of the inner wall of the hydrogen distillation chamber 310 are symmetrically provided with a plurality of liquid collection mechanisms, the liquid collection mechanisms are connected with an oil outlet 314 that runs through the wall of the hydrogenation distillation chamber 310, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com