Method for removing melting solder paste gas holes on heat pipe radiator

A heat pipe radiator, fusion welding technology, applied in welding equipment, auxiliary devices, metal processing equipment, etc., can solve the problems of affecting the heat dissipation effect, residual air holes, increased contact thermal resistance, etc., to improve welding quality and heat dissipation effect. Excellent, the effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

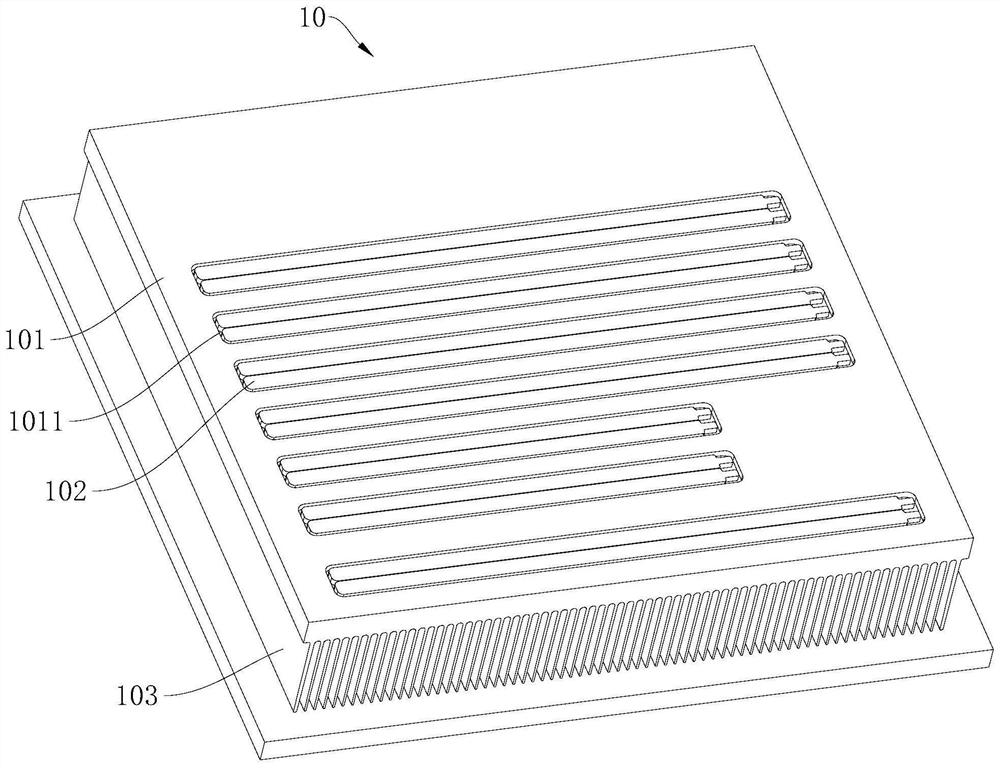

[0029] see figure 1 , shows the heat pipe radiator 10 mentioned in the present invention, the heat pipe radiator 10 at least includes a base 101, a number of heat pipes 102 and a number of heat dissipation fins 103, the top surface of the base 101 shown in the figure is the same as the outside The surface of the heat source that the heat source contacts, the top surface of the base 101 is provided with a number of heat pipe grooves 1011 adapted to the shape of the heat pipe 102, the heat pipe 102 is welded in the heat pipe groove 1011, the heat pipe 102 has at least one plane, and the plane and the base 101 The top surface of the base is on the same l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com