Preparation method of 6082 aluminum alloy spectral standard sample

A spectral standard sample and aluminum alloy technology, which is applied in the field of preparation of 6082 aluminum alloy spectral standard samples to achieve the effect of no pores, uniform chemical composition and fine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a 6082 aluminum alloy spectral standard sample, comprising the following steps:

[0029] a), melting and blending aluminum source, silicon source, iron source, copper source, manganese source, magnesium source, chromium source, nickel source, zinc source and titanium source to obtain an aluminum alloy melt;

[0030] The aluminum alloy melt comprises: 1.0-1.3wt% Si; 0.2-0.5wt% Fe; 0.04-0.05wt% Cu; 0.7-1.0wt% Mn; 1.0-1.2wt% Mg; 0.25wt% Cr; 0.05-0.06wt% Ni; 0.1-0.2wt% Zn; 0.04-0.06wt% Ti and the rest Al;

[0031] b) The aluminum alloy melt is sequentially cast, homogenized heat treated and extruded to obtain a 6082 aluminum alloy spectral standard sample.

[0032]In the present invention, firstly, aluminum source, silicon source, iron source, copper source, manganese source, magnesium source, chromium source, nickel source, zinc source and titanium source are melt blended to obtain an aluminum alloy melt. Wherein, the silicon...

Embodiment 1

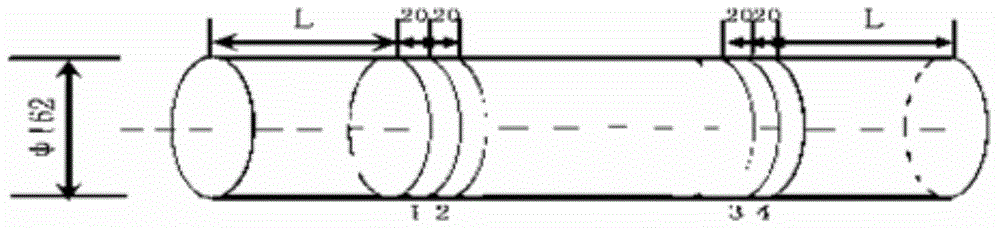

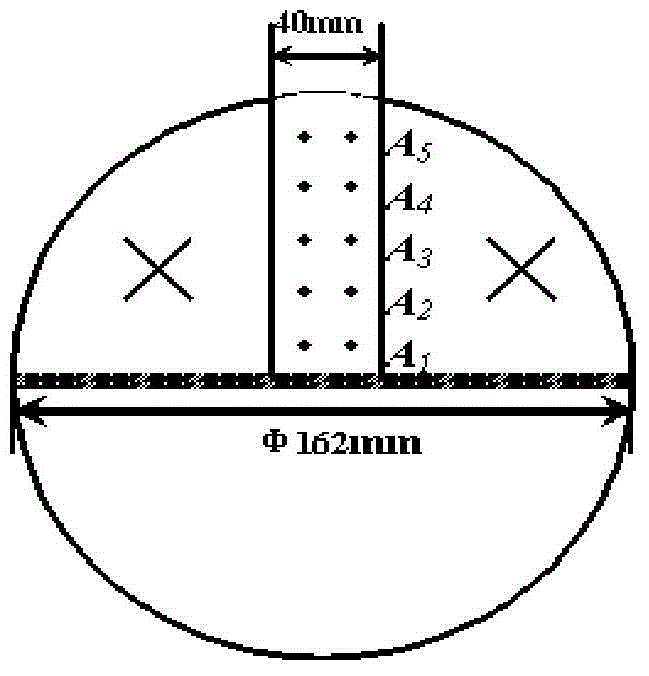

[0052] Pure aluminum, Al-20wt% Si master alloy, Al-15wt% Fe master alloy, Al-40wt% Cu master alloy, Al-15wt% Mn master alloy, Al-4wt% Cr master alloy, The Al-20wt% Ni master alloy and the Al-20wt% Ti master alloy were put into the furnace, melted and blended at 760° C. to obtain the first alloy melt. Add pure zinc into the first alloy melt according to the composition percentage in Table 1, and stir to obtain the second alloy melt. Add pure magnesium into the second alloy solution according to the composition ratio in Table 1, and stir to obtain an aluminum alloy melt. Under stirring conditions, hot-top casting is used to cast the aluminum alloy melt. The casting temperature is 735°C, the casting speed is 78mm / min, and the cooling water pressure is 0.06MPa. After the casting, an aluminum alloy with a diameter of 162mm is obtained. Alloy ingots and rods.

[0053] The chemical composition mass percent of 6082 aluminum alloy spectral standard sample in the embodiment 1 of table...

Embodiment 2

[0069] Pure aluminum, Al-20wt% Si master alloy, Al-15wt% Fe master alloy, Al-40wt% Cu master alloy, Al-15wt% Mn master alloy, Al-4wt% Cr master alloy, The Al-20wt% Ni master alloy and the Al-20wt% Ti master alloy were put into the furnace, melted and blended at 760° C. to obtain the first alloy melt. Add pure zinc into the first alloy melt according to the composition percentage in Table 2, and stir to obtain the second alloy melt. Add pure magnesium into the second alloy solution according to the composition ratio in Table 2, and stir to obtain an aluminum alloy melt. Under stirring conditions, hot-top casting is used to cast the aluminum alloy melt. The casting temperature is 745°C, the casting speed is 72mm / min, and the cooling water pressure is 0.08MPa. After the casting, an aluminum alloy with a diameter of 162mm is obtained. Alloy ingots and rods.

[0070] The chemical composition mass percent of 6082 aluminum alloy spectral standard sample in the embodiment 2 of table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com