Cardanol and saturated cardanol based surfactant, preparation method therefor and application of cardanol and saturated cardanol based surfactant

A surfactant, cardanol-based technology, applied in the field of cardanol and saturated cardanol-based surfactants and their preparation, can solve the problems of high temperature resistance, salt resistance, etc., and achieve good emulsification performance and biodegradability , the effect of strong surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of preparation method of cardanol and saturated cardanol-based surfactant, is characterized in that, comprises the following steps:

[0034] S1 alkalized cardanol and reacted with diamine to obtain intermediate 1;

[0035] S2 puts cardanol into the reactor, adds a sulfonating agent for sulfonation to obtain cardanol sulfonic acid;

[0036] S3 reacts cardanol sulfonic acid with epichlorohydrin under alkaline conditions to obtain intermediate 2;

[0037] S4 Mix and heat intermediate 1 and intermediate 2, add sulfonic acid to the product after reaction, perform sulfonation and add lye to neutrality;

[0038] S5 Separating and purifying the obtained product to obtain the cardanol surfactant containing trisiloxane and amino group.

[0039] In the present invention, the concentration range of the lye is 6wt% to a saturated solution; the lye is selected from sodium hydroxide, potassium hydroxide, sodium carbonate, sodium bicarbonate, potassium carbonate, potassium car...

Embodiment 1

[0045] Cardanol, epichlorohydrin, and diamine aqueous solution are the main raw materials, and the product is obtained through a chemical reaction of substitution and ring-opening quaternization, and 0.05mol cardanol, 33% diamine aqueous solution, and 10ml of absolute ethanol are added to the conical flask As a solvent, at 50 degrees Celsius, slowly add 6 g of epichlorohydrin (0.065 mol) dropwise under the condition of magnetic stirring, pass in nitrogen gas and stir evenly, and keep warm for 6 hours. The sulfonating agent is a chlorosulfonic acid solution (chlorosulfonic acid 0.58mol). After the sulfonating agent is added, the reaction is carried out at room temperature for 2 to 8 hours; and an organic solvent, the obtained solid is dissolved in absolute ethanol, and desalted to obtain the surfactant.

[0046] The solvent, unreacted diamine and epichlorohydrin were evaporated under reduced pressure, washed with acetone and dried in vacuo for purification.

Embodiment 2

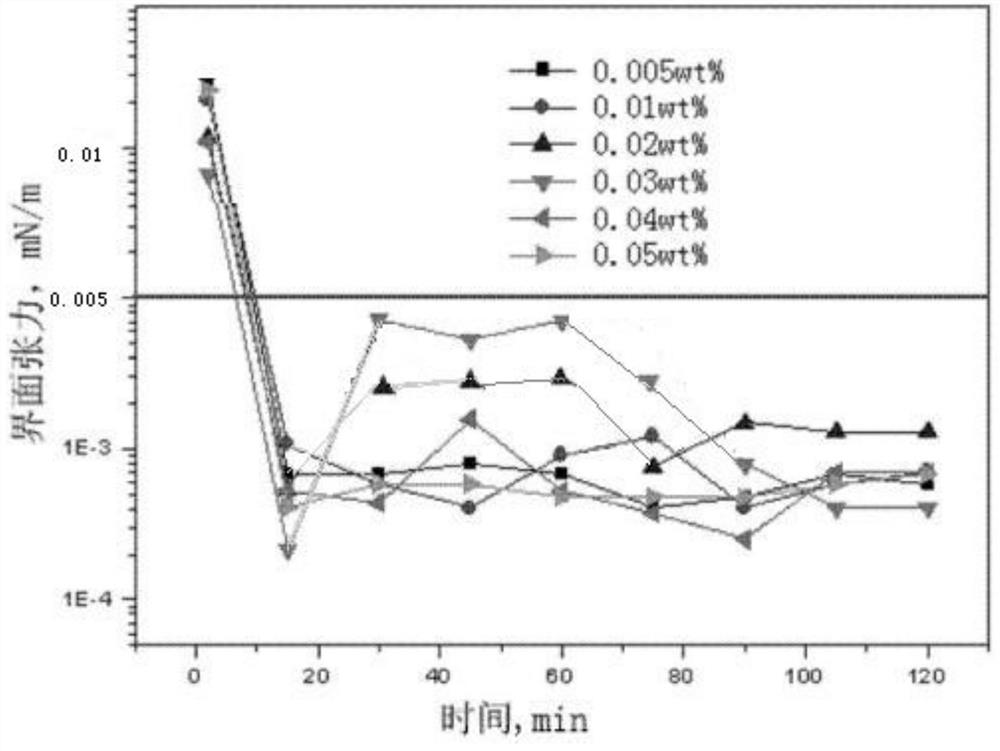

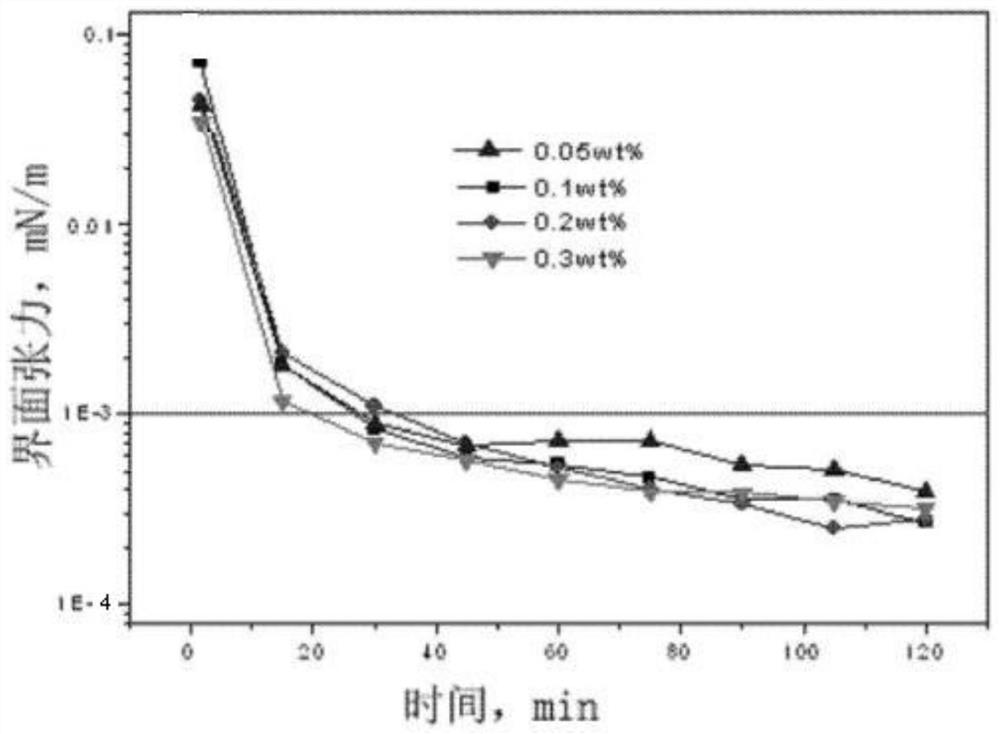

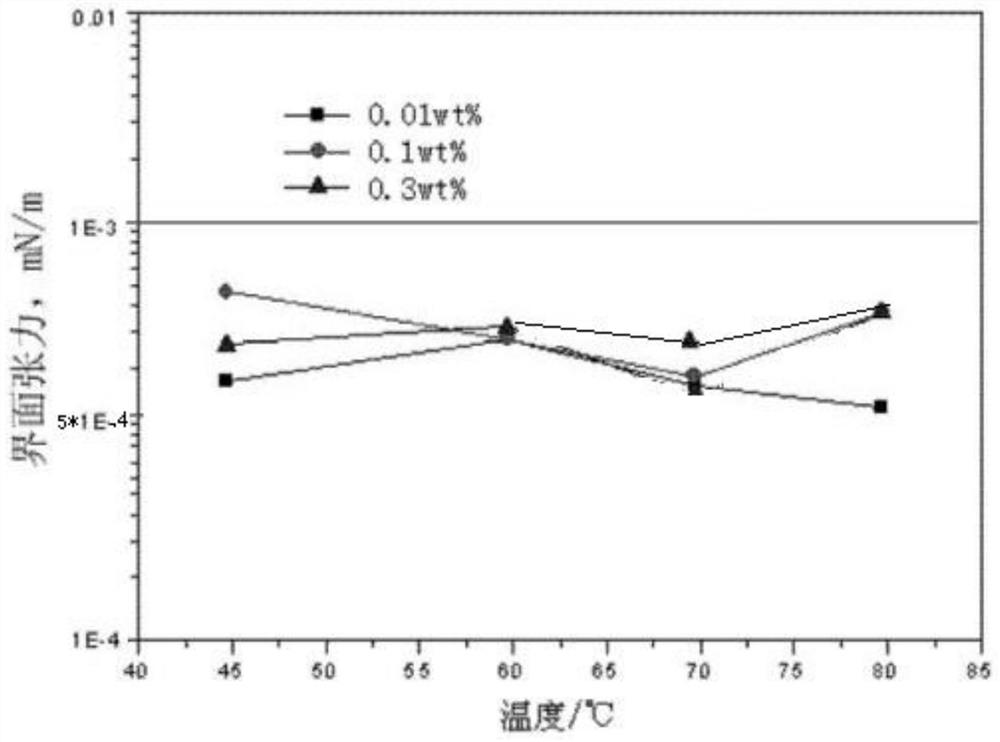

[0048] Ultra-low interfacial tension experiment of one-component system

[0049] The cardanol and saturated cardanol-based surfactants provided by the present invention have excellent ability and effectiveness of reducing interfacial tension, especially still have good interfacial activity at a very low concentration of use. The cardanol and saturated cardanol provided in Example 1 and Saturated cardanol-based surfactant in the one-component system of 50-500ppm concentration (i.e. the aqueous solution of cardanol and saturated cardanol-based surfactant provided in Example 1) and Daqing No. 1 Plant oil-water interfacial tension test results are as follows figure 1 shown. It can be seen that within the concentration range of 50-500ppm, the interfacial tension of the system reaches ultra-low, and the interface performance is excellent, which shows that the cardanol and saturated cardanol-based surfactants provided in Example 1 have good performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com