Ginseng granule and preparation method

A technology of granules and ginseng, which is applied in the direction of anti-toxic agents, pharmaceutical formulas, medical preparations of non-active ingredients, etc., can solve problems such as the preparation method of granules for obtaining ginseng extract, and achieve the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Preparation of ginseng extract:

[0058] Weigh ginseng coarse powder, add distilled water according to the material-to-liquid ratio of 1:30, mix well, adjust the pH of the mixture to 4.7, add 0.6% pectinase, shake the water bath at 60°C for 4 hours, take out the boiling water bath for 5 minutes to inactivate the enzyme, and wait for cooling Centrifuge at 4°C, 8000r / min for 10min, and keep the supernatant. The bottom residue obtained by centrifugation was added to distilled water at a solid-to-liquid ratio of 1:50, extracted by flash homogenization at 2800r / min for 4 minutes, centrifuged to retain the supernatant, and combined with the enzymatic hydrolysis supernatant, and the resulting combined filtrate was the ginseng extract. The ginseng extract is concentrated by evaporation under reduced pressure to obtain an extract with a relative density of 1.20-1.30 at a temperature of 50-60°C.

[0059] The ginseng extracts used in the subsequent examples and comparative exampl...

Embodiment 2

[0061] The present embodiment provides the preparation method of ginseng granules, comprising the following steps:

[0062] S1, mix the ginseng extract and the selected excipients in proportion, after drying, use an appropriate amount of ethanol as a wetting agent to make a soft material, put it in a tray, mix evenly, hold it into a ball, lightly press it and then disperse Can;

[0063] S2, if it is necessary to prepare samples with flavoring agents added, after mixing the flavoring agents and soft materials, they are rolled and granulated by a rolling granulator (YK160), and then dried in a vacuum drying oven; If there is no need to add flavoring agent, the agglomerated granulated soft material without flavoring agent is directly rolled and granulated by a rolling granulator (YK160), and then placed in a vacuum drying oven to dry;

[0064] S3, whole grain.

[0065] Among them, in S1, drying is carried out at -100Kpa, 50°C, and in S2, the drying pressure is -100Kpa.

[0066...

Embodiment 3

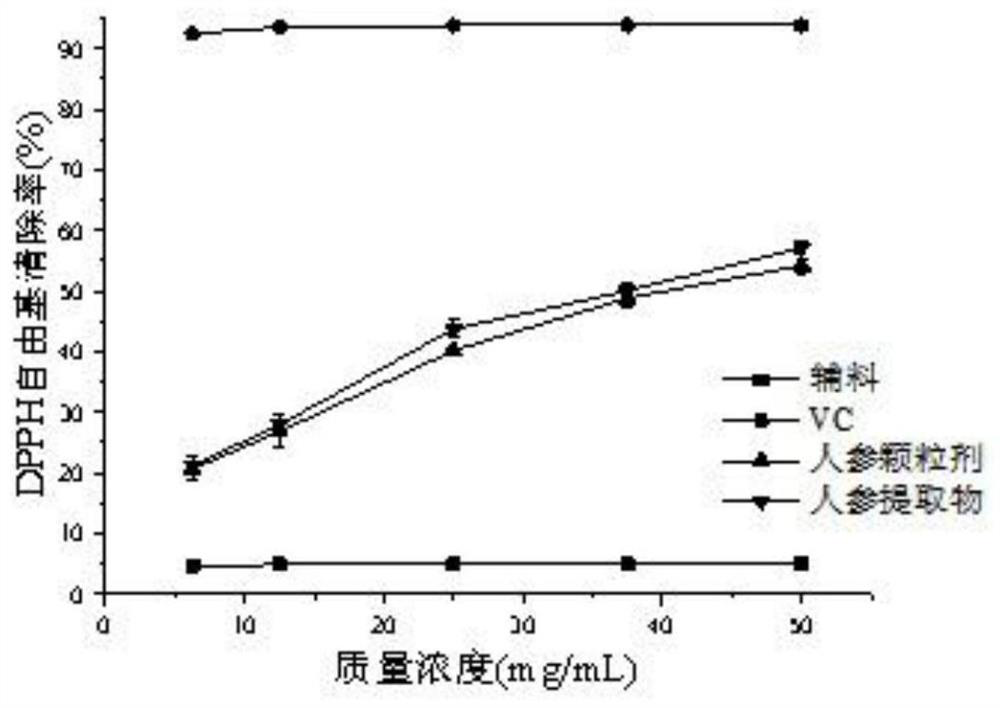

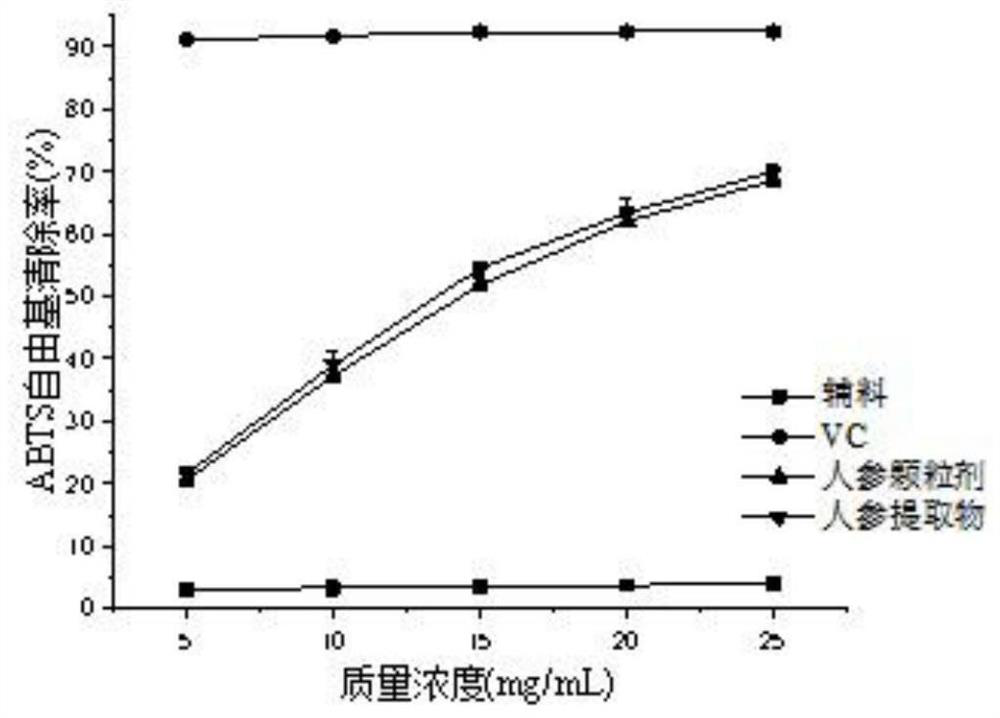

[0081] Carry out product testing to each type of ginseng granules of embodiment 2 and comparative example 1 respectively, and the testing items are corresponding as follows:

[0082] 3.1 Test the molding rate of the granules of models S1-S12, S14, S22-S30 in Example 2 and the granules of models D1-D3 in the comparative example.

[0083] 3.2 Evaluate the comprehensive quality of S1, S3, and S5 excipients. The evaluation method is: three parallel measurements of the moisture absorption rate, dissolution rate, molding rate, angle of repose, and bulk density of the sample, and the results are used as various indicators to calculate the comprehensive score. Calculated as follows:

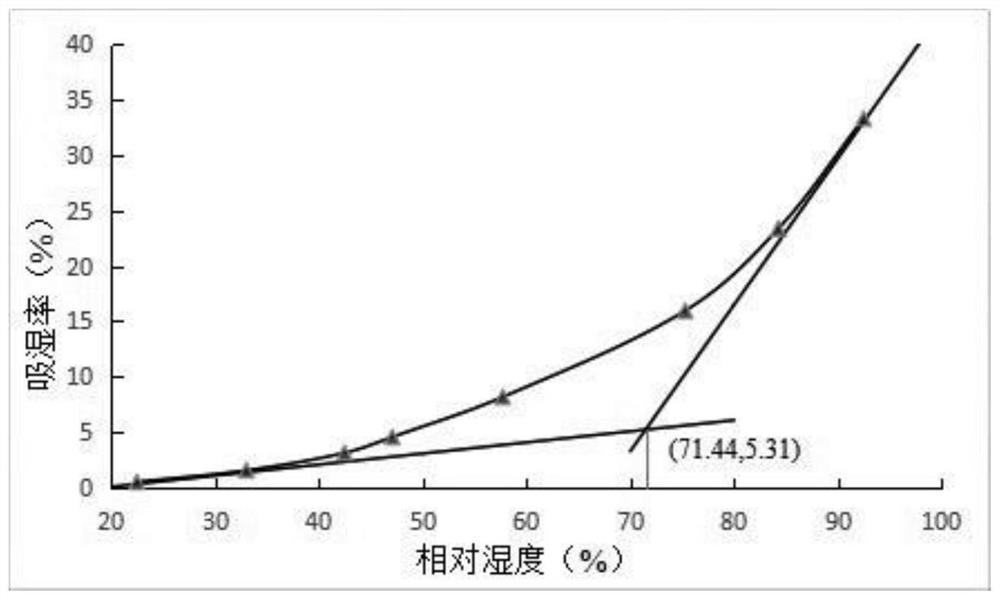

[0084] Comprehensive index = 15×forming rate / maximum forming rate+20×dissolving rate value / maximum dissolving rate value+15×bulk density value / maximum bulk density value+15×minimum angle of repose / angle of repose value+35×minimum moisture absorption value / Moisture absorption rate value, moisture absorp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com