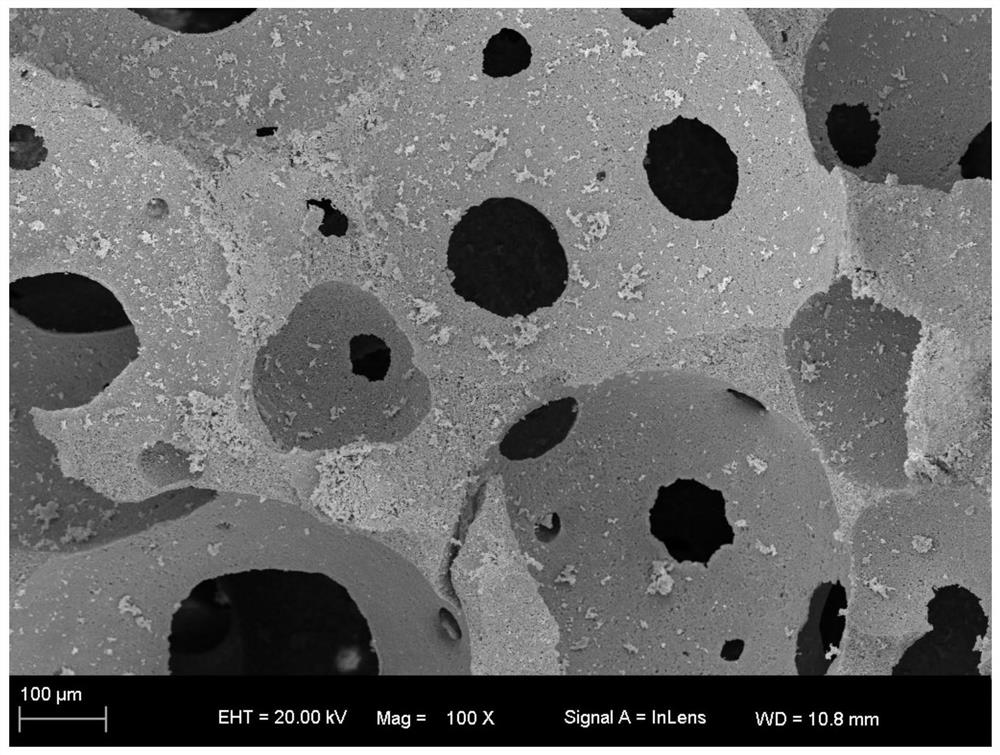

A sound-absorbing and noise-reducing porous ceramic used in substations

A technology of porous ceramics and substations, applied in ceramic products, applications, household appliances, etc., can solve problems such as air pollution, low sound absorption coefficient in low frequency areas, toxicity, etc., achieve no toxic gas emissions, avoid human injury, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A sound-absorbing and noise-reducing porous ceramic for a substation, the preparation of which comprises the following steps:

[0042] S1: mixing of raw materials: mixing 5g kaolin, 3g clay, and 2g mica powder to obtain a binder A, and then mixing the binder, 10g albite and 15g commercial alumina to obtain a mixed powder a with a total amount of 35g;

[0043] S2: Slurry preparation: add 28g of deionized water to the mixed powder a and mix to obtain a slurry with a solid content of 55.56%, add 0.14g of dispersant sodium hexametaphosphate and gelling agent B to the slurry, this implementation In the example, the gelling agent B includes 0.056g konjac flour and 0.196g K-type carrageenan, and is ball-milled for 4h at a rotational speed of 250 rpm to obtain slurry b;

[0044] S3: Foaming injection molding: put the slurry b in a ball milling tank, and mill it for 8 hours, then add 014 g of foaming agent C sodium lauryl sulfate to the slurry B, and continue the ball milling fo...

Embodiment 2

[0051] A sound-absorbing and noise-reducing porous ceramic for a substation, the preparation of which comprises the following steps:

[0052] S1: Mixing of raw materials: Mix 5g of kaolin, 3g of clay, and 3g of mica powder to obtain a binder A, and then mix the binder, 11g of albite and 16.5g of commercial alumina to obtain a mixed powder with a total amount of 38.5g a;

[0053] S2: Slurry preparation: add 28g of deionized water to the mixed powder a and mix to obtain a slurry with a solid content of 57.89%, add 0.14g of dispersant sodium hexametaphosphate and gelling agent B to the slurry, this implementation In the example, the gelling agent B includes 0.056g konjac flour and 0.196g K-type carrageenan, and is ball-milled for 5h at a rotational speed of 250 rpm to obtain slurry b;

[0054] S3: Foaming injection molding: put the slurry b in a ball milling tank, ball mill for 8 hours, then add 0.14g of foaming agent C sodium lauryl sulfate to the slurry B, and continue ball mi...

Embodiment 3

[0058] A sound-absorbing and noise-reducing porous ceramic for a substation, the preparation of which comprises the following steps:

[0059] S1: mixing of raw materials: mixing 5g kaolin, 2g clay, and 3g mica powder to obtain a binder A, and then mixing the binder, 20g albite and 30g commercial alumina to obtain a mixed powder a with a total amount of 60g;

[0060]S2: Slurry preparation: add 48g of deionized water to the mixed powder a and mix to obtain a slurry with a solid content of 55.56%, add 0.24g of dispersant sodium hexametaphosphate and gelling agent B to the slurry, this implementation In the example, the gelling agent B includes 0.144g konjac flour and 0.384g K-type carrageenan, and is ball-milled for 3.5h at a rotational speed of 250 rpm to obtain slurry b;

[0061] S3: Foaming injection molding: put the slurry b in a ball milling tank, ball mill for 12 hours, then add 0.288g of foaming agent C sodium lauryl sulfate to the slurry B, and continue ball milling for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Refractory temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com