Treatment system for wastewater of kitchen waste aerobic degradation treatment plant

A food waste and treatment system technology, applied in aerobic and anaerobic process treatment, oxidized water/sewage treatment, sludge treatment, etc., can solve environmental pollution and other problems, achieve high organic matter content, and good air flotation separation effect , To ensure the stable operation of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

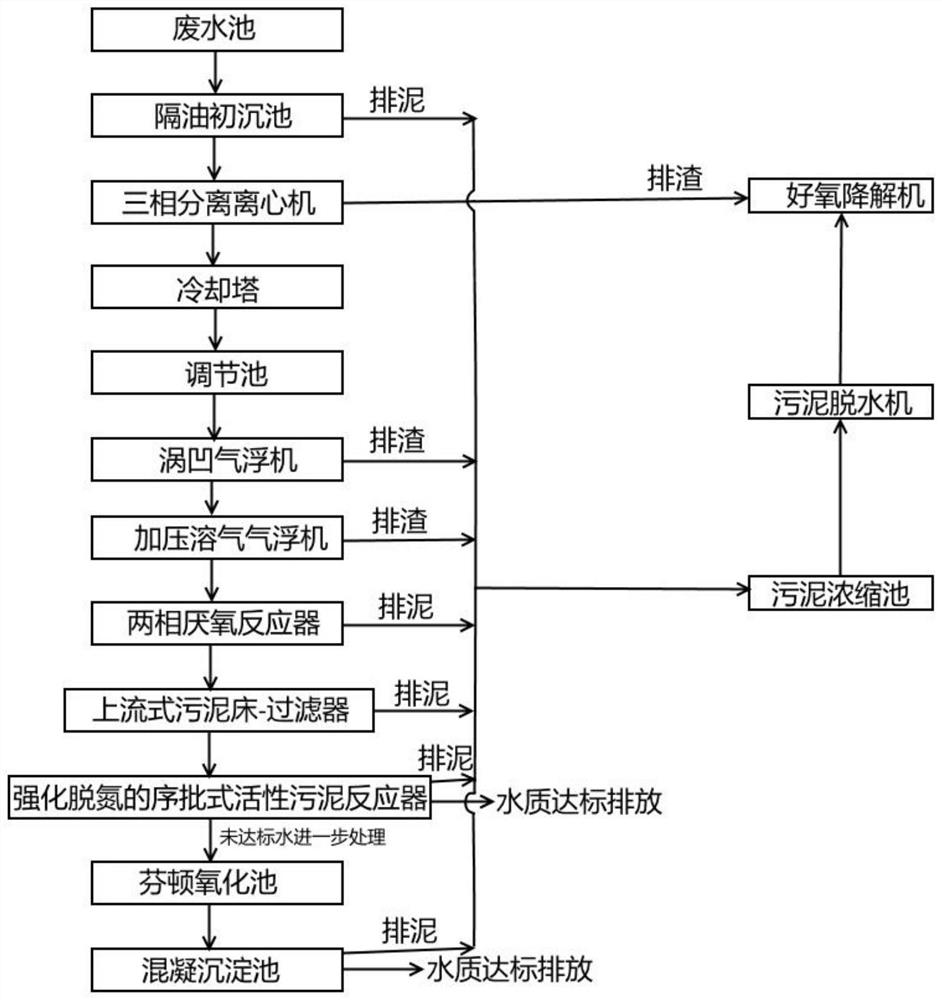

[0027] The treatment system of the waste water of the food waste aerobic degradation treatment plant described in this embodiment, see figure 1 , including wastewater tank, oil separation primary sedimentation tank, three-phase separation centrifuge, cooling tower, regulating tank, vortex concave air flotation machine, pressurized dissolved air flotation machine, two-phase anaerobic reactor, upflow sludge bed- Filter, sequence batch activated sludge reactor for enhanced denitrification, the water outlet of the waste water tank is connected with the oil-separated primary sedimentation tank, the water outlet of the oil-separated primary sedimentation tank is connected with a three-phase separation centrifuge, and the three-phase separation The water outlet of the centrifuge is connected to the cooling tower, the water outlet of the cooling tower is connected to the regulating tank, the water outlet of the regulating pool is connected to the vortex concave air flotation machine, a...

Embodiment 2

[0049] The waste water treatment system of the food waste aerobic degradation treatment plant described in this embodiment includes a waste water tank, an oil separation primary sedimentation tank, a three-phase separation centrifuge, a cooling tower, a regulating tank, a vortex concave air flotation machine, and a pressurized dissolved air Air flotation machine, two-phase anaerobic reactor, upflow sludge bed-filter, sequence batch activated sludge reactor for enhanced denitrification, the outlet of the waste water tank is connected to the oil separation primary sedimentation tank, and the oil separation The water outlet of the primary sedimentation tank is connected to the three-phase separation centrifuge, the water outlet of the three-phase separation centrifuge is connected to the cooling tower, the water outlet of the cooling tower is connected to the regulating tank, and the water outlet of the regulating tank is connected to the vortex concave air flotation machine. The ...

Embodiment 3

[0057]The waste water treatment system of the food waste aerobic degradation treatment plant described in this embodiment includes a waste water tank, an oil separation primary sedimentation tank, a three-phase separation centrifuge, a cooling tower, a regulating tank, a vortex concave air flotation machine, and a pressurized dissolved air Air flotation machine, two-phase anaerobic reactor, upflow sludge bed-filter, sequence batch activated sludge reactor for enhanced denitrification, the outlet of the waste water tank is connected to the oil separation primary sedimentation tank, and the oil separation The water outlet of the primary sedimentation tank is connected to the three-phase separation centrifuge, the water outlet of the three-phase separation centrifuge is connected to the cooling tower, the water outlet of the cooling tower is connected to the regulating tank, and the water outlet of the regulating tank is connected to the vortex concave air flotation machine. The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com