Part grinding device

A technology for parts and grinding heads, which is applied to grinding drive devices, abrasive surface adjustment devices, grinding/polishing safety devices, etc., and can solve problems affecting processing and gear blank deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

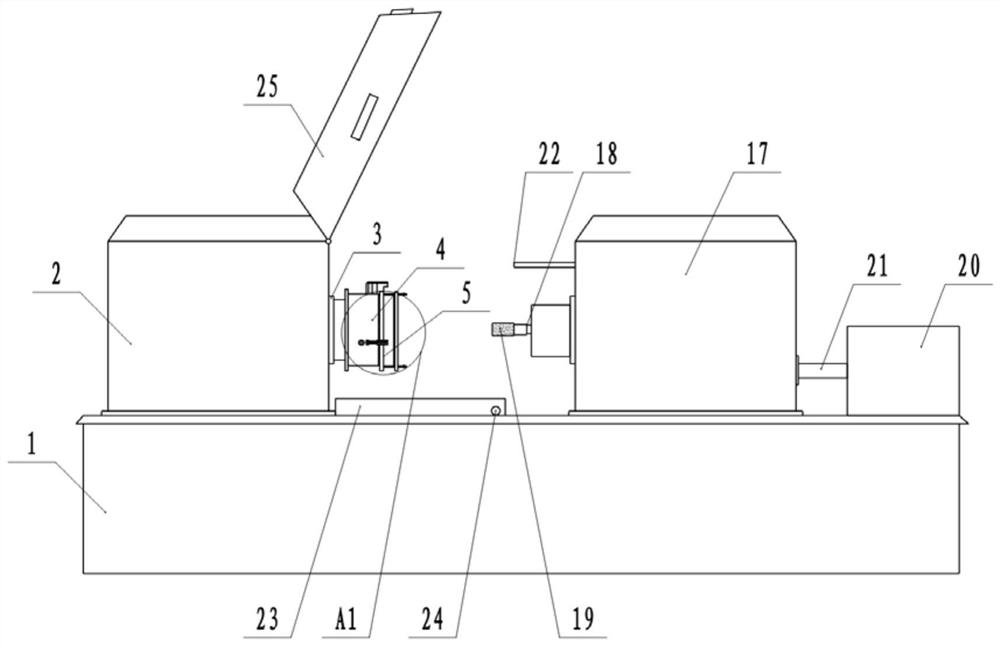

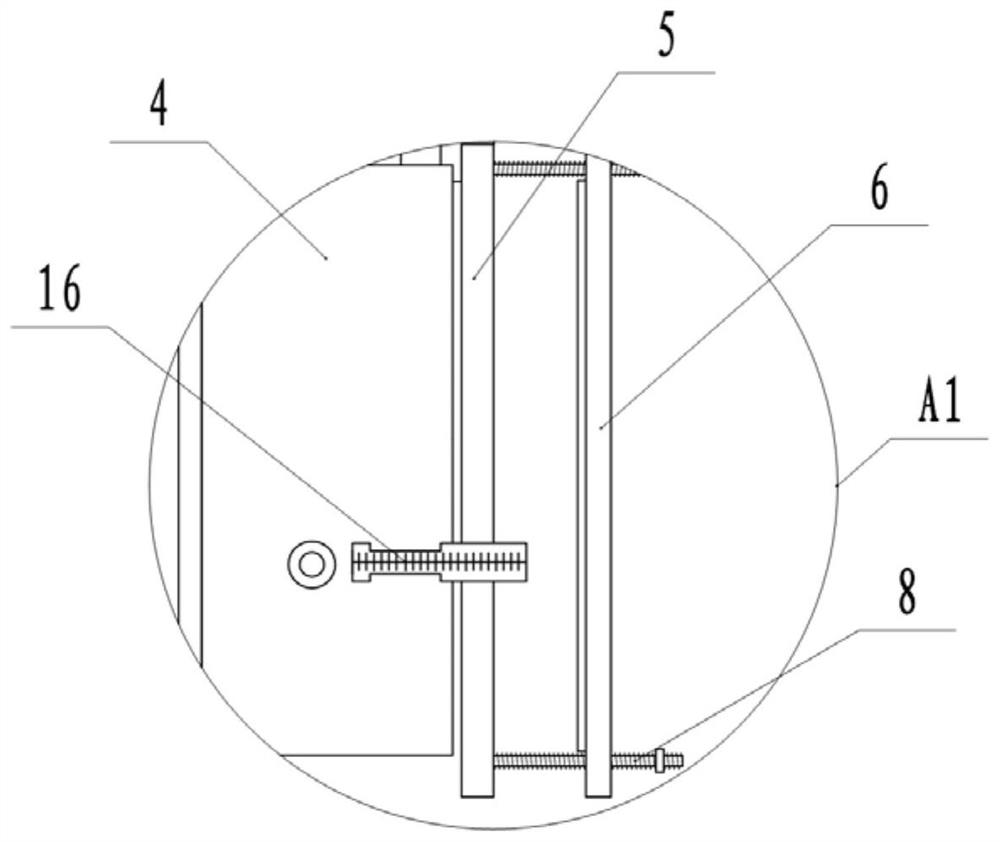

[0036] This embodiment is basically as attached figure 1 Shown: a parts grinding device, including a frame 1, a clamping mechanism, a grinding mechanism and a cleaning mechanism.

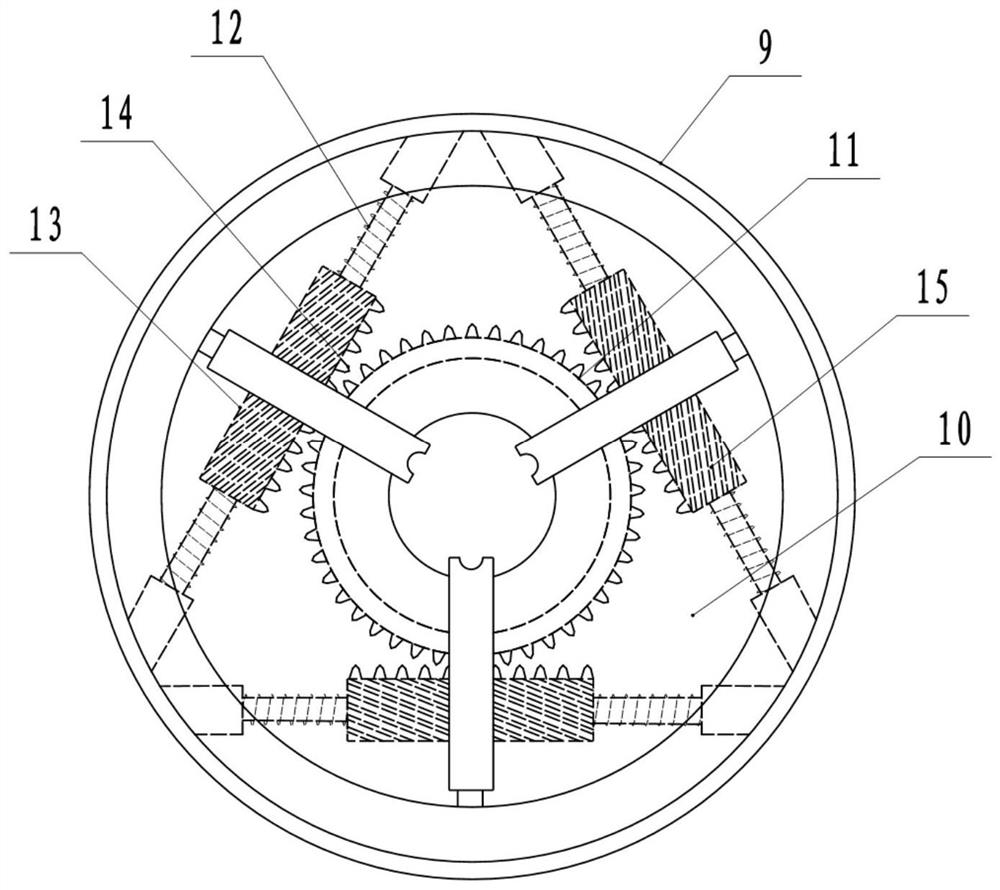

[0037] The frame 1 plays the role of supporting and ensuring the stable connection between the equipment. The clamping mechanism is used to clamp and fix the workpiece to be polished. The clamping mechanism includes the support platform 2 welded on the frame 1, and the right side of the support platform 2 A support disc 3 is fixedly connected to the wall, and the support disc 3 is rotatably connected with a clamping chuck 4, combined with Figure 3-Figure 5As shown, the clamping chuck 4 includes a chuck seat 9 and a chuck body 10, the chuck seat 9 is rotatably connected to the support plate 3, and the side of the chuck seat 9 away from the support plate 3 is coaxially fixed with a drive gear 11 , three threaded rods 12 are rotatably connected to the chuck seat 9, and the three threaded rods 12 are ...

Embodiment 2

[0046] like Figure 7 , Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that in this embodiment, a correction mechanism is also provided on the frame 1, and the correction mechanism is used for grinding the outer surface of the polished grinding head 19 , to restore a certain roughness. The correction mechanism includes a slideway 26 fixedly connected to the frame 1. The slideway 26 is arranged across the front and rear ends of the frame 1. The slideway 26 is slidably connected with a correction base 27, and the correction base 27 is rotatably connected with a correction frame. 28, the top of the correction frame 28 is fixedly connected with a handwheel 29, and the bottom end of the correction frame 28 is rotatably connected with a correction head 30 that can face the grinding head 19.

[0047] In the process of using the grinding head 19 to grind the inner hole of the gear, since the force is mutual, as the equipment is used for a long time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com