Method for preparing nickel-titanium two-way memory deformation part and intelligent structure through 4D printing

A technology of memory deformation and intelligent structure, which is applied in the direction of additive processing, etc., can solve the problems of poor processing performance of nickel-titanium alloy, difficulty in forming complex parts, difficult to realize two-way memory effect of complex parts, etc., and achieve the effect of solving difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

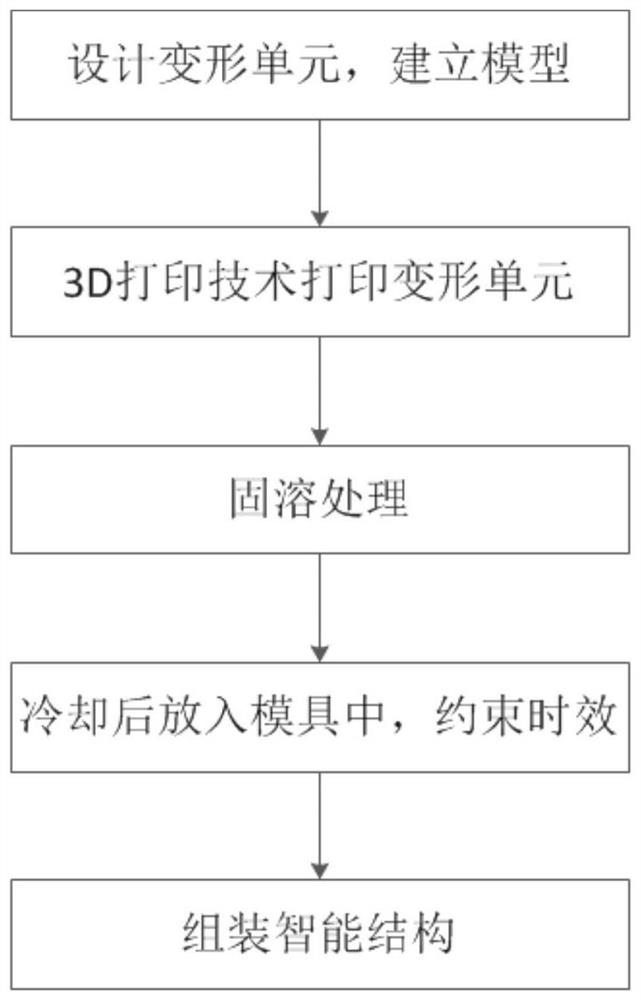

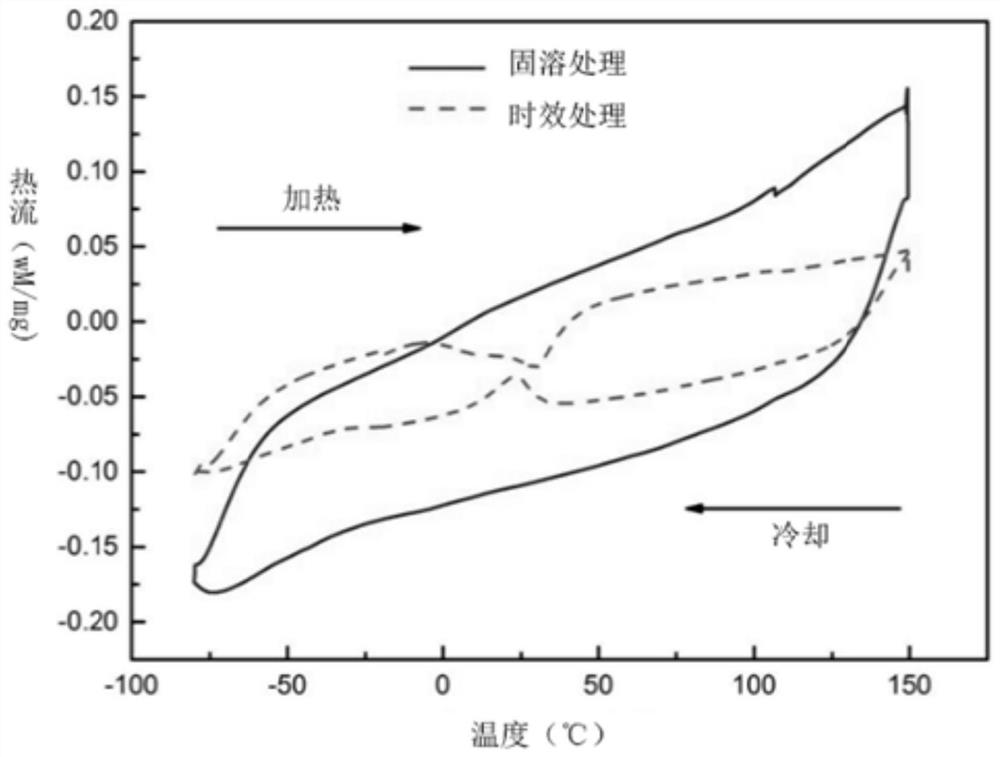

[0039] Aiming at the 4D printing intelligent structure technology described in the present invention, a 50.8 Ti 49.2 Powder is prepared as raw material such as Figure 5 The technological process of the rounded rhombus deformation unit, its steps are as follows:

[0040](1) First design the intelligent structure according to the requirements, determine the installation method of the deformation unit, and establish the computer three-dimensional model of the deformation unit. Nickel-titanium shape memory alloy is used as the material of the deformation unit, and a suitable constraining mold is selected according to the deformation requirements.

[0041] (2) with Ni 50.8 Ti 49.2 The powder is used as the raw material, and the deformation unit is prepared by Directed Energy Deposition (DED). The equipment cabin is first vacuumed, and then argon is introduced as the protective gas. Before printing starts, the substrate needs to be preheated to 150°C to prevent cracks. Under ...

Embodiment 2

[0046] Aiming at the 4D printing intelligent structure technology described in the present invention, a 50.8 Ti 49.2 The technical process for preparing the rounded rhombus deformation unit as a raw material, the steps are as follows:

[0047] First, design the intelligent structure according to the requirements, determine the installation method of the deformation unit, and establish the computer three-dimensional model of the deformation unit. Select the appropriate restraint mold according to the deformation requirements.

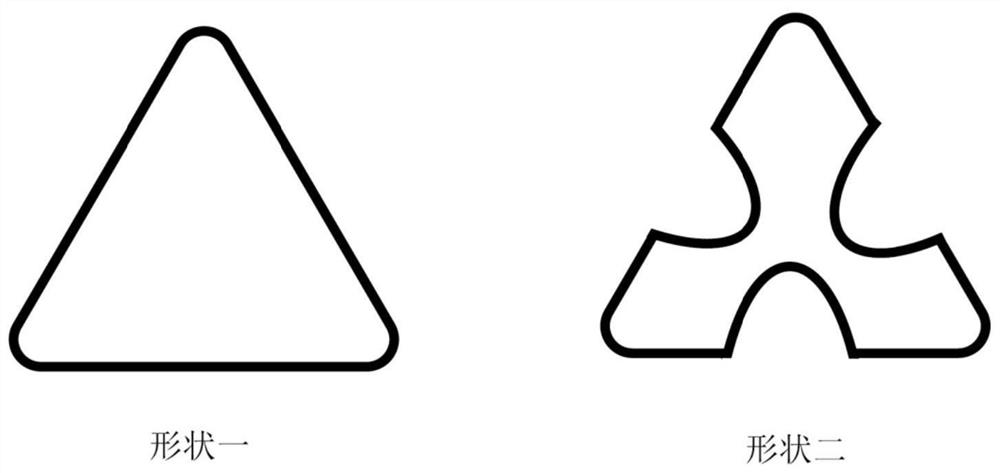

[0048] With Ni 50.8 Ti 49.2 Wire is used as the raw material, and the deformation unit is prepared by Directed Energy Deposition (DED). The equipment cabin is first vacuumed, and then argon is introduced as the protective gas. Before printing starts, the substrate needs to be preheated to 180°C to prevent cracks. Under the parameters of current 60A, machine speed 2mm / s, wire feeding speed 20mm / s. Figure 6 Shape one of the deformation unit shown. ...

Embodiment 3

[0052] Aiming at the 4D printing intelligent structure technology described in the present invention, a 50.8 Ti 49.2 Silk is prepared as a raw material such as Figure 6 The technological process of the shown rounded triangle deformation unit, its steps are as follows:

[0053] First, design the intelligent structure according to the requirements, determine the installation method of the deformation unit, and establish the computer three-dimensional model of the deformation unit. Nickel-titanium shape memory alloy is used as the material of the deformation unit, and a suitable constraining mold is selected according to the deformation requirements.

[0054] With Ni 50.8 Ti 49.2 Wire is used as the raw material, and the deformation unit is prepared by Directed Energy Deposition (DED). The equipment cabin is first vacuumed, and then argon is introduced as the protective gas. Before printing starts, the substrate needs to be preheated to 200°C to prevent cracks. Under the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com