A kind of composite negative electrode material, negative electrode, lithium ion battery and preparation method

A negative electrode material and negative electrode technology, applied in the field of electrochemical materials, can solve the problems of poor initial charge and discharge capacity and cycle performance, and achieve the effects of reducing local current density, alleviating continuous growth, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of composite negative electrode material:

[0030] Step 1. Cut the commercial melamine foam resin into a shape of 5cm×5cm×3cm, put it into a tube furnace, and carbonize it at 1200°C for 2h under the protection of nitrogen atmosphere, wash it with absolute ethanol after cooling, and dry it at 60°C , and then cut to obtain a foamed carbon matrix of 5cm×5cm×0.1cm;

[0031] Step 2: Put the metal lithium foil into the crucible, heat to 250°C to completely melt the metal lithium foil to obtain molten lithium; immerse the foamed carbon matrix in the molten lithium for 2 minutes, take it out and let it cool naturally to obtain the composite Negative material.

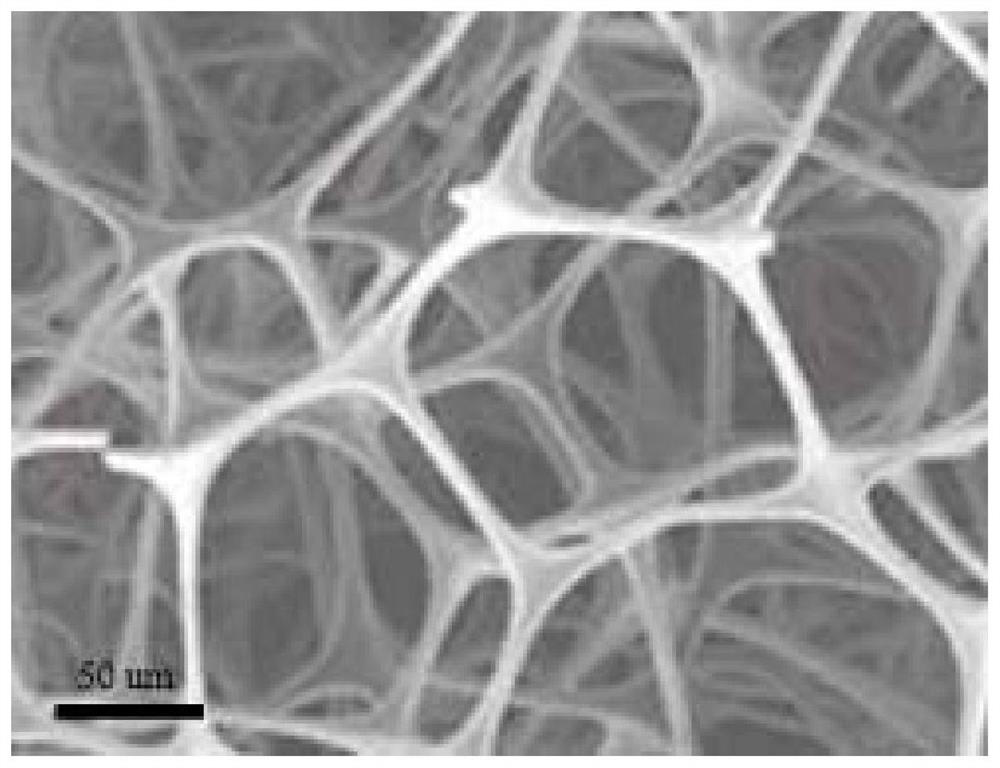

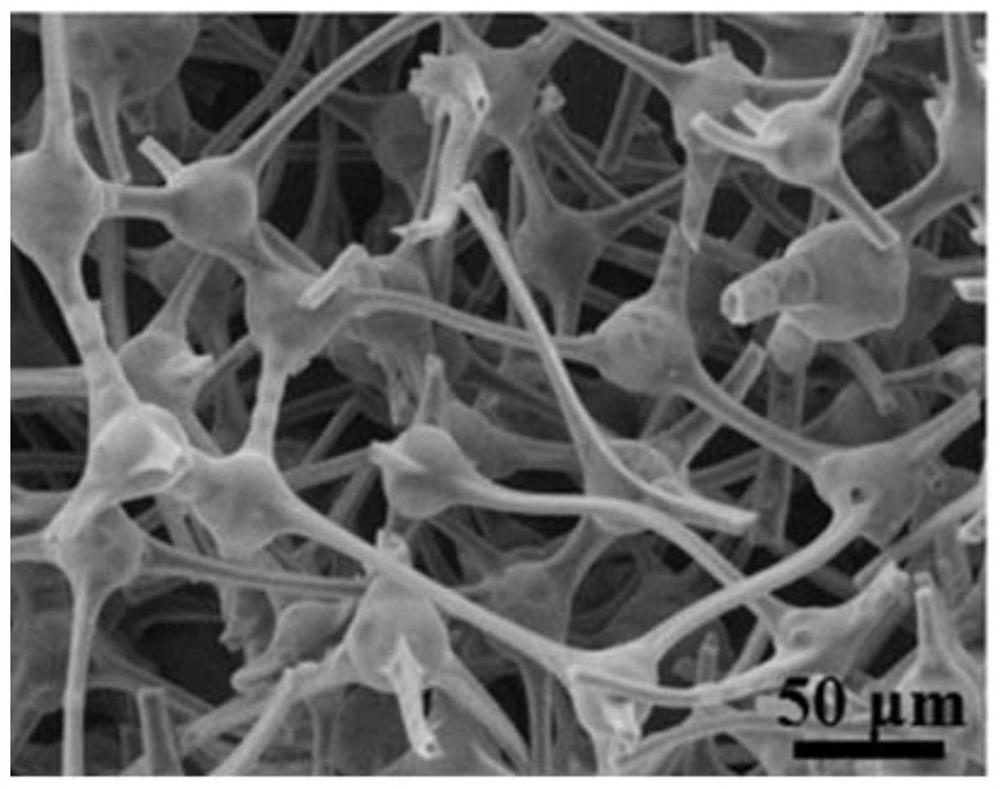

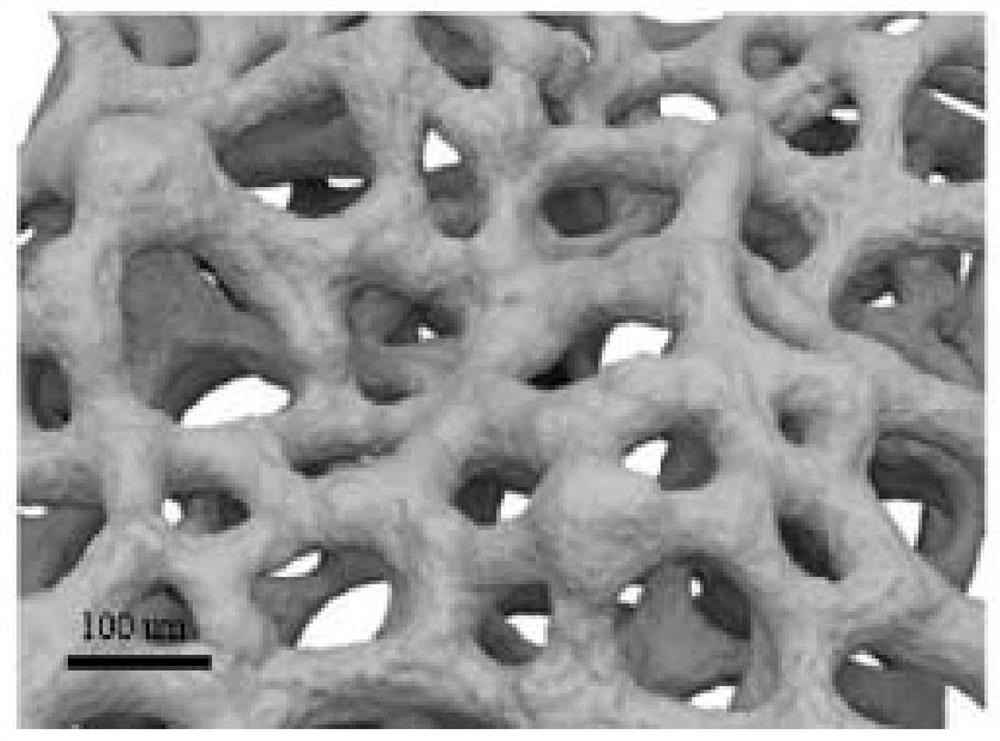

[0032] figure 1 Be the SEM figure of described melamine foam resin, figure 2 It is the SEM picture of carbonized foamed carbon matrix. It can be seen from the figure that the prepared foamed carbon matrix has a high open porosity, the open porosity can reach 99%, and the distribution of pores is ...

Embodiment 2

[0039] A preparation method of composite negative electrode material:

[0040] Step 1. Cut the commercial melamine foam resin into a shape of 5cm×5cm×3cm, put it into a tube furnace, and carbonize it at 1000°C for 4h under the protection of nitrogen atmosphere, wash it with absolute ethanol after cooling, and dry it at 60°C , and then cut to obtain a foamed carbon matrix of 5cm×5cm×0.1cm;

[0041] Step 2: Put the metal lithium foil into the crucible, heat to 180°C to completely melt the metal lithium foil to obtain molten lithium; immerse the foamed carbon matrix in the molten lithium for 4 minutes, take it out and let it cool naturally to obtain the composite Negative material.

Embodiment 3

[0043] A preparation method of composite negative electrode material:

[0044] Step 1. Cut the commercial melamine foam resin into a shape of 5cm×5cm×3cm, put it into a tube furnace, and carbonize it at 1300°C for 3h under the protection of nitrogen atmosphere, wash it with absolute ethanol after cooling, and dry it at 60°C , and then cut to obtain a foamed carbon matrix of 5cm×5cm×0.1cm;

[0045] Step 2: Put the metal lithium foil into the crucible, heat to 500°C to completely melt the metal lithium foil to obtain molten lithium; immerse the foamed carbon matrix in the molten lithium for 6 minutes, take it out and let it cool naturally to obtain the composite Negative material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com