Novel phosphorus-free cold pad-batch pretreatment auxiliary agent and application thereof

A technology for pre-treatment and additives for cold stacks, applied in fiber treatment, dry-cleaning fiber products, plant fibers, etc., can solve problems such as restricting industrial applications, and the phosphorus content of sewage does not meet environmental protection requirements, and achieves balanced treatment effects and good whiteness. , strong damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

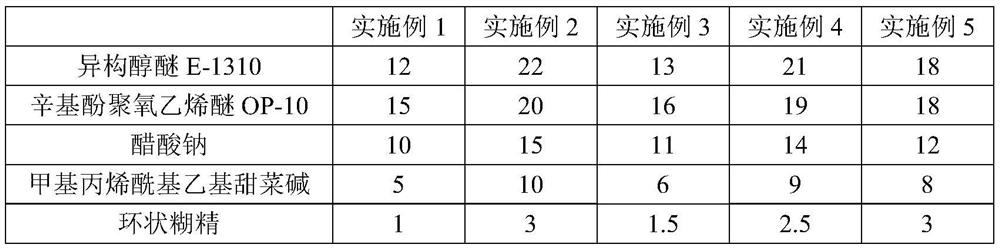

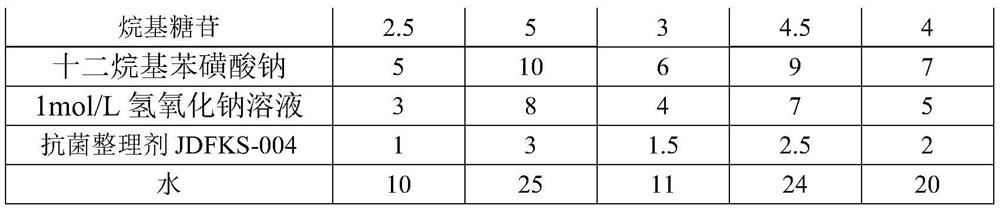

[0042] Embodiment 1-5 A kind of novel phosphorus-free cold reactor pretreatment aid

[0043] Examples 1-5 are the components and dosage (parts by weight) of the new phosphorus-free cold reactor pretreatment additive, as shown in Table 1.

[0044] Table 1

[0045]

[0046]

[0047] The preparation method is:

[0048] S1. Mix the isomeric alcohol ether, octylphenol polyoxyethylene ether, methacryloyl ethyl betaine and sodium dodecylbenzenesulfonate in the formula amount, heat up to 50°C, and stir at a speed of 60rpm for 15- After 20 minutes, cool to room temperature 25°C to obtain an emulsion;

[0049] S2, mixing and dissolving the water, sodium acetate and cyclodextrin in the formula amount to obtain solution 1;

[0050]S3. Add the emulsion obtained in step S1 to the solution 1 in step S2, stir for 15-20min, add 1mol / L sodium hydroxide solution to adjust the pH value, then add the antibacterial agent in the formula, and continue stirring for 10-15min , filter and disc...

experiment example 1

[0063] Experimental example 1. Phosphorus content test

[0064] According to GB11893-89 D, the phosphorus content test is carried out to the novel phosphorus-free cold reactor pretreatment additive of embodiment 1-5, find that the phosphorus content of the novel phosphorus-free cold reactor pretreatment additive prepared by the embodiment of the present invention 1-5 is 0ppm. It shows that the novel phosphorus-free cold reactor pretreatment additive prepared by the invention does not contain phosphorus and meets the latest environmental protection requirements.

experiment example 2

[0065] Experimental example two, penetration

[0066] Penetration test method: test the standard canvas sheet in the working fluid (20-21°C) of the corresponding concentration of the new phosphorus-free cold reactor pretreatment additive prepared in Examples 1-5 and Comparative Examples 1-4 from the contact liquid level to the settlement For the time taken to the bottom, the working fluid is 3g / L new phosphorus-free cold reactor pretreatment additive, 60g / L caustic soda+6g / L new phosphorus-free cold reactor pretreatment additive; the results are shown in Table 2.

[0067] Table 2

[0068]

[0069] As can be seen from the above table, according to Examples 1-5, the novel phosphorus-free cold reactor pretreatment aid prepared by the present invention has good penetration under alkali-free or alkali-free environments; Ratio 1 found that when the weight ratio of isomeric alcohol ether, octylphenol polyoxyethylene ether and methacryloyl ethyl betaine was 9:9:4, the penetration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com