Polyester elastomer-based neck hanging line shaping material as well as preparation method and application thereof

A polyester elastomer and polyolefin elastomer technology, which is applied in the field of hanger thread setting material and its preparation, can solve the problems of high impact strength, easy breakage of the hanger thread, and high breaking strength, and achieves hard yellowing and light suppression. Aging degradation, improve the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

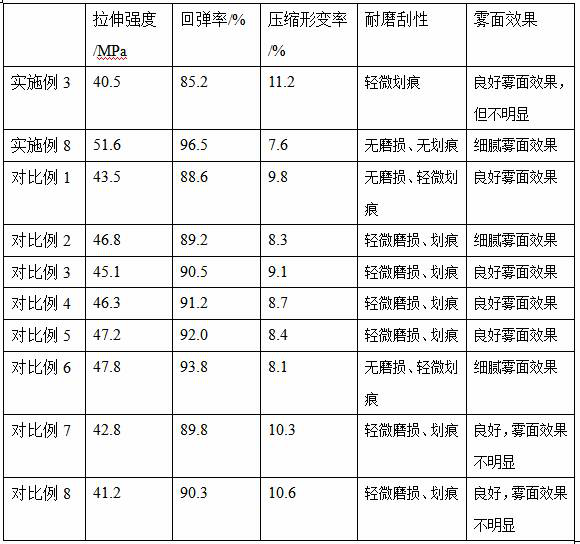

Examples

Embodiment 1

[0054] A kind of hanging neck thread setting material based on polyester elastomer, said hanging neck thread setting material is made of raw materials comprising the following parts by weight:

[0055] Polyester elastomer 50 parts

[0056] TPU 15 parts

[0057] 10 parts polyolefin elastomer

[0058] Compatibilizer 3 parts

[0059] Lubricant 1 part

[0060] Auxiliary 3 parts.

[0061] The polyester elastomer is selected from American DuPont 4069 brand thermoplastic polyester elastomer.

[0062] The polyolefin elastomer is selected from American DuPont 8200 brand polyolefin elastomer.

[0063] The compatibilizer is GMA-g-PE.

[0064] Described lubricant is methyl ethoxy silicone oil.

[0065] Each part of said auxiliary agent includes 2 parts of antioxidant and 1 part of anti-UV agent; said antioxidant is 1,3,5-three (3,5-di-tert-butyl-4-hydroxyphenyl) isocyanate; said The anti-UV agent is light stabilizer 770.

[0066] A method for preparing a polyester elastomer-based...

Embodiment 2

[0069] A kind of hanging neck thread setting material based on polyester elastomer, said hanging neck thread setting material is made of raw materials comprising the following parts by weight:

[0070] Polyester elastomer 55 parts

[0071] TPU 18 parts

[0072] Polyolefin elastomer 14 parts

[0073] 3.5 parts of compatibilizer

[0074] Lubricant 1.5 parts

[0075] Auxiliary 3.2 parts.

[0076] The polyester elastomer is selected from American DuPont 4069 brand thermoplastic polyester elastomer.

[0077] The polyolefin elastomer is selected from American DuPont 8200 brand polyolefin elastomer.

[0078] The compatibilizer is GMA-g-PP.

[0079] The lubricant is ethyl silicone oil.

[0080] Each part of said auxiliary agent includes 2.2 parts of antioxidant and 1.2 parts of anti-UV agent; said antioxidant is pentaerythritol bis-diphosphite bis (2,4-di-tert-butylphenyl) ester; said anti-UV agent is Light stabilizer 622.

[0081] A method for preparing a polyester elastomer...

Embodiment 3

[0084] A kind of hanging neck thread setting material based on polyester elastomer, said hanging neck thread setting material is made of raw materials comprising the following parts by weight:

[0085] Polyester elastomer 60 parts

[0086] TPU 20 parts

[0087] Polyolefin elastomer 18 parts

[0088] Compatibilizer 4 parts

[0089] Lubricant 2 parts

[0090] Auxiliary 3.5 parts.

[0091] The polyester elastomer is selected from American DuPont 4069 brand thermoplastic polyester elastomer.

[0092] The polyolefin elastomer is selected from American DuPont 8200 brand polyolefin elastomer.

[0093] The compatibilizer is SEBS-g-MAH.

[0094] Described lubricant is benzyl silicone oil.

[0095] Each part of the auxiliary agent includes 2.5 parts of antioxidant and 1.5 parts of anti-UV agent; the antioxidant is N, N'-hexamethylene bis (3, 5-di-tert-butyl-4-hydroxyphenylpropanamide) ; The anti-UV agent is ultraviolet absorber UV-327.

[0096] A method for preparing a polyester ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com