Red mud-based calcium sulphosilicate-calcium aluminoferrite cement raw material, cement clinker, cement and preparation method thereof

A technology of calcium sulfosilicate and calcium ferric aluminate, applied in the field of cement, can solve problems such as reducing the sintering temperature of cement clinker, and achieve the effects of improving curing ability, avoiding efflorescence phenomenon and enhancing solid solution ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0045] A method for preparing red mud-based calcium sulfosilicate-calcium aluminoferrite cement clinker, comprising the steps of:

[0046] (1) In parts by weight, 45 parts of limestone, 20 parts of red mud, 10 parts of barium slag, 30 parts of aluminum ash, and 20 parts of fluorogypsum were uniformly mixed, and ground through a 100-mesh sieve to obtain cement raw meal.

[0047] (2) Sprinkle water on the cement raw meal obtained in step (1), then press it into a cake in a mold, dry the obtained raw meal cake, and then calcinate the raw meal cake at 1125°C for 5min, and after completion, the obtained product Quenched in air to obtain cement clinker.

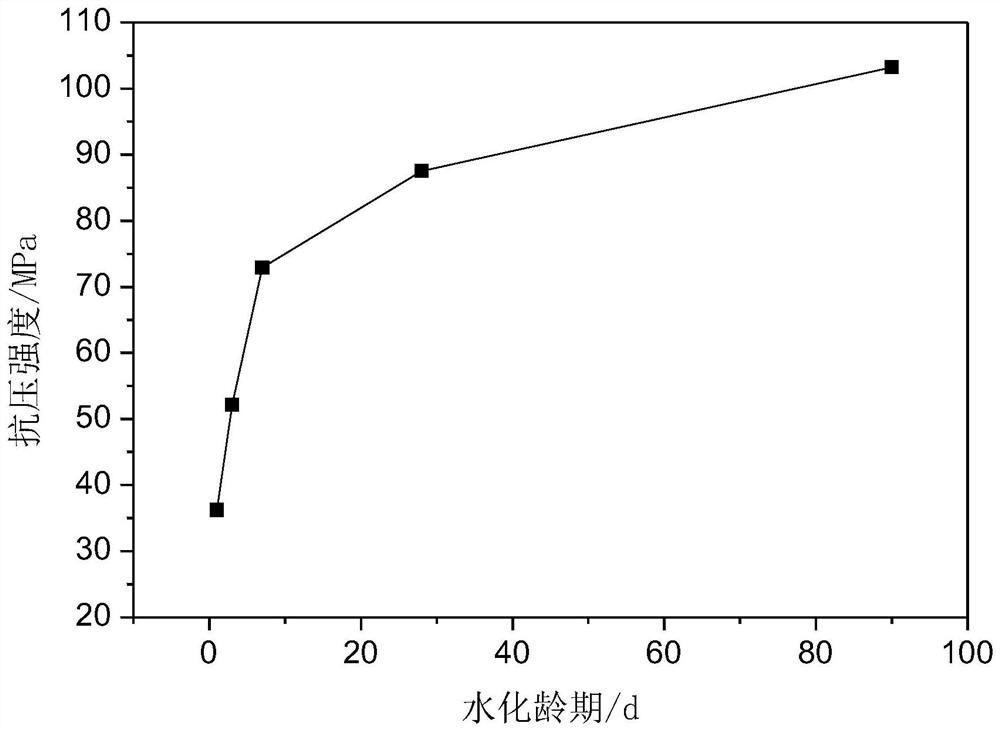

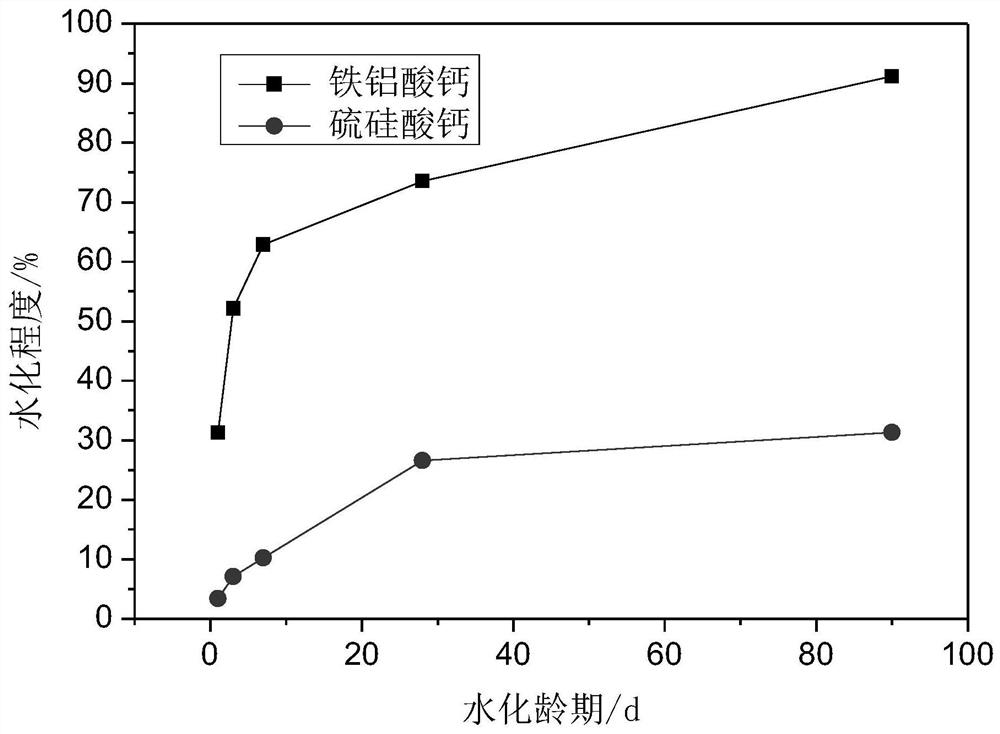

[0048] Performance Testing

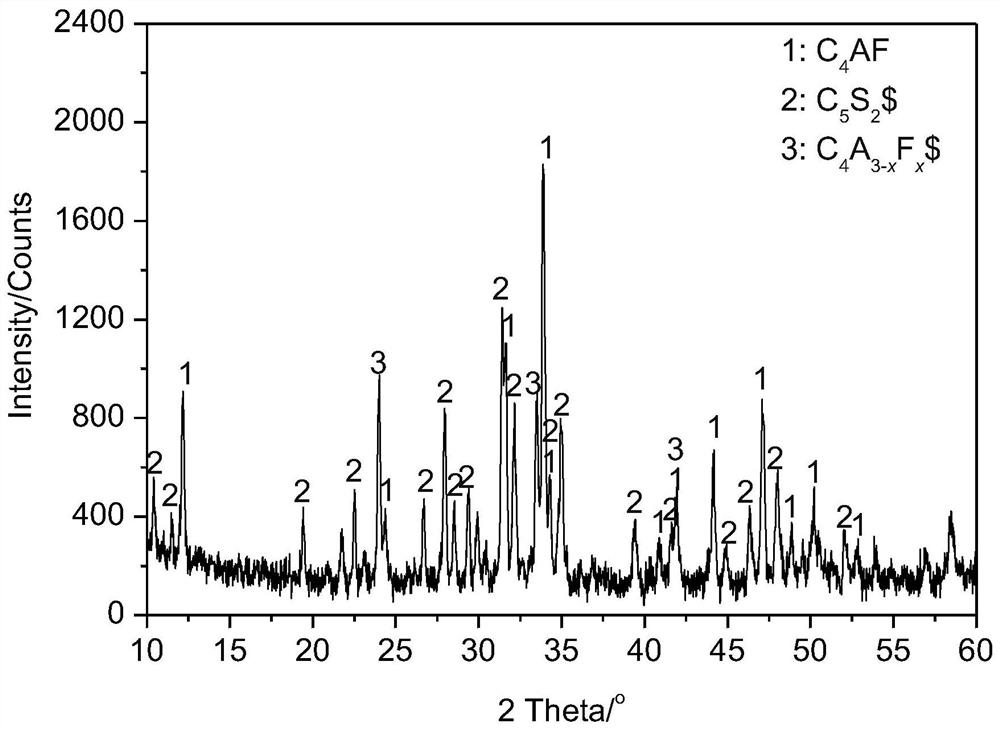

[0049] (1) Carry out X-ray diffraction analysis to the cement clinker prepared by the present embodiment, and test the mineral composition of cement clinker by Rietveld quantitative analysis method, refer to figure 1 , its main mineral composition is 25% (mass) of calcium aluminoferrite, 45% (mass) ...

no. 2 example

[0056] A method for preparing red mud-based calcium sulfosilicate-calcium aluminoferrite cement clinker, comprising the steps of:

[0057] (1) In parts by weight, mix 50 parts of carbide slag, 30 parts of red mud, 15 parts of strontium slag, 20 parts of bauxite tailings, and 20 parts of borogypsum, and grind them through a 100-mesh sieve to obtain raw cement material.

[0058] (2) Sprinkle water on the cement raw meal obtained in step (1) and stir it evenly, then press it into a cake in a mold, dry the obtained raw meal cake, and then calcinate the raw meal cake at 1100°C for 20min, after completion, put The resulting product is quenched in air to obtain cement clinker.

[0059] Performance Testing

[0060] (1) Carry out X-ray diffraction analysis to the cement clinker prepared in this embodiment, and test the mineral composition of cement clinker by Rietveld quantitative analysis method, its main mineral composition is calcium aluminoferrite 47% (mass), calcium sulfosilic...

no. 3 example

[0065] A method for preparing red mud-based calcium sulfosilicate-calcium aluminoferrite cement clinker, comprising the steps of:

[0066] (1) In parts by weight, 45 parts of limestone, 35 parts of red mud, 15 parts of barium slag, 25 parts of bauxite tailings, and 15 parts of borogypsum were uniformly mixed, and ground through a 100-mesh sieve to obtain cement raw meal.

[0067] (2) Sprinkle water on the cement raw meal obtained in step (1) and stir it evenly, then press it into a cake in a mold, dry the obtained raw meal cake, and then calcinate the raw meal cake at 1150°C for 20min, after completion, put The resulting product is quenched in air to obtain cement clinker.

[0068] Performance Testing

[0069] (1) Carry out X-ray diffraction analysis to the cement clinker prepared in this embodiment, and test the mineral composition of cement clinker by Rietveld quantitative analysis method, its main mineral composition is 60% (mass) of calcium aluminum ferrite, calcium sul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com