Process for solving problem of layering during graphene processing

A graphene and problem-solving technology, applied in the field of graphene die-cutting processing, can solve the problems of large gap between products, easy delamination of heavy films, easy deviation of light films, etc., to reduce delamination rate, reduce peeling force, Ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

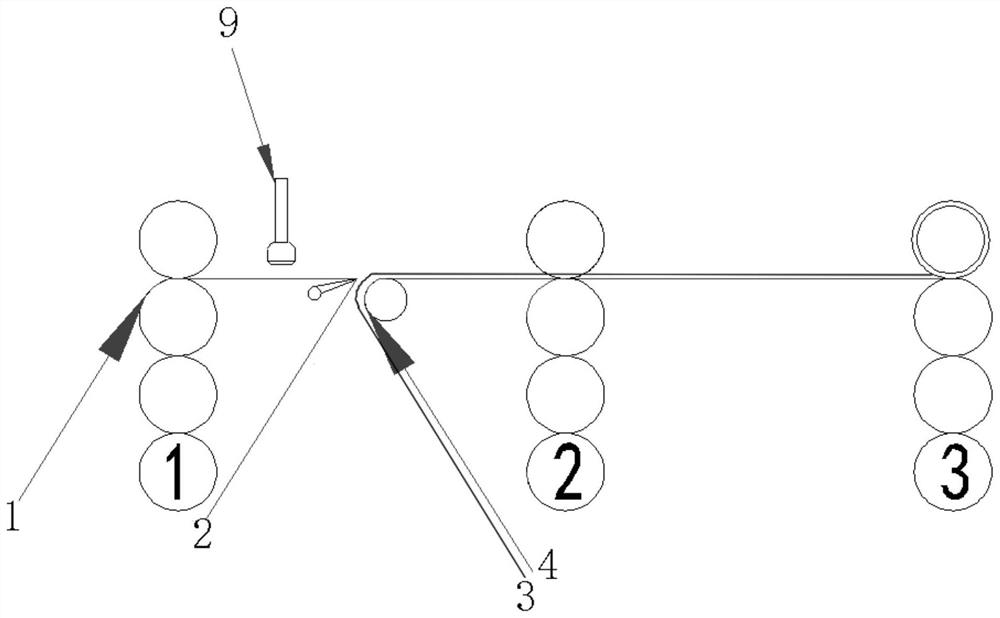

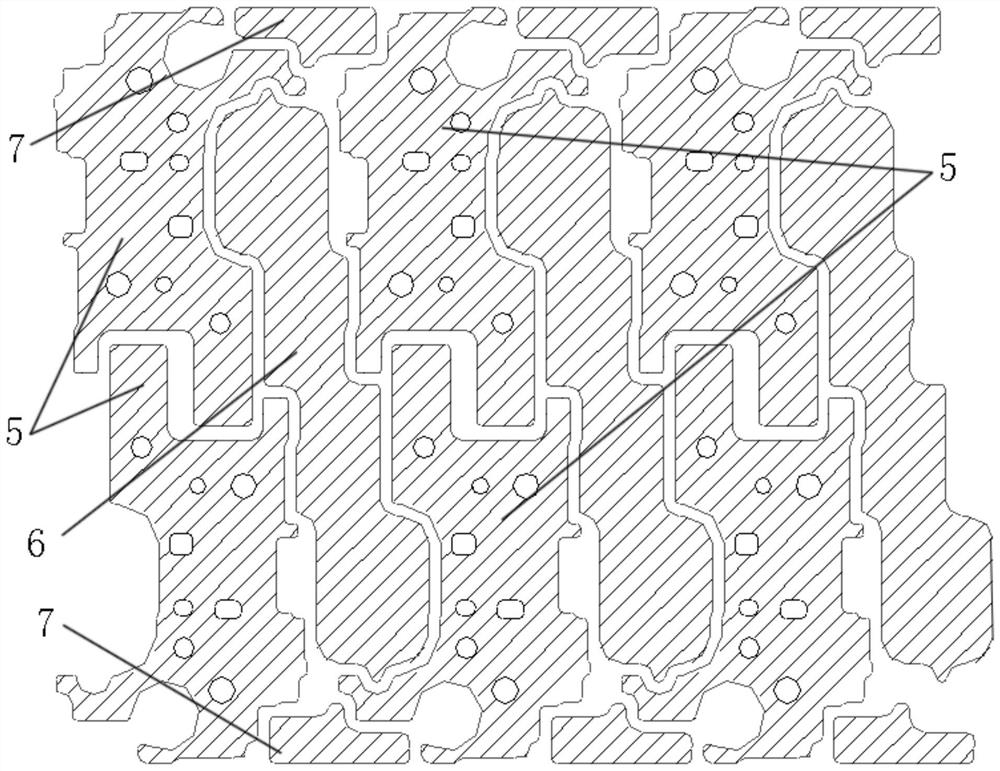

[0017] A process to solve the problem of delamination during graphene processing, see figure 1 , figure 2 : Before die-cutting, the self-contained film 2 of the graphene 1 is peeled off, and then the release film 4 with the double-sided adhesive layer 3 is laminated on the back of the graphene 1, and the upper surface of the double-sided adhesive layer 3 is bonded with graphite Then the graphene 1 bonded with the release film 4 through the double-sided adhesive layer 3 is cut by a knife die, and the gap area between the two adjacent sets of products 5 of different sheets is cut into Filling the middle area, the filling middle area and the products 5 adjacent to each other are not connected to each other.

[0018] The viscosity of the double-sided adhesive layer 3 is 500g / inch~1000g / inch;

[0019] The double-sided adhesive layer 3 is specifically an organic material silicone layer, and the specific thickness of the double-sided adhesive layer 3 is 0.005±0.0005mm to ensure that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com