Manufacturing method for warm rolling of stainless steel/carbon steel composite board

A technology of stainless steel and clad plate, applied in the field of clad plate production, can solve the problems of low surface strength of hot-rolled clad plate, deterioration of stamping performance, decrease of toughness and plastic index, etc., to achieve high production efficiency, prevention of element diffusion, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Manufacture of 304 / Q235 warm-rolled stainless steel-carbon-steel clad plate with anti-seepage layer added

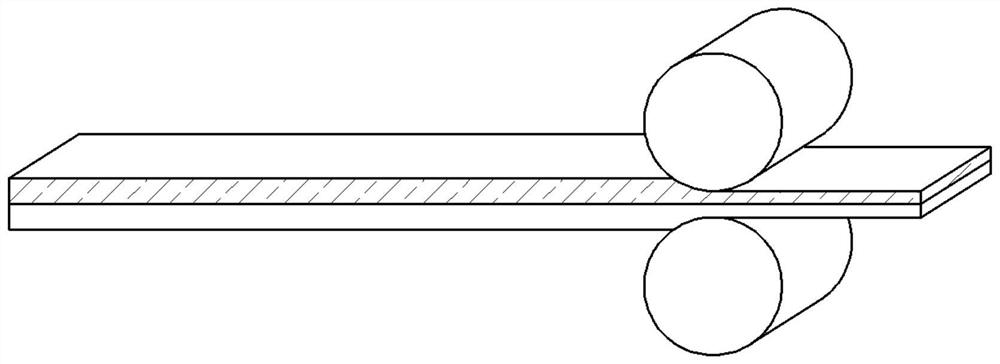

[0031] Such as figure 1 As shown, the surface-treated 304 stainless steel plate blank is coated with an anti-seepage layer. The upper layer is 304 stainless steel plate, and the lower layer is Q235 carbon steel plate, which are symmetrically combined. The anti-seepage layer is in the middle of the interface between stainless steel and carbon steel. The thickness of the stainless steel plate is 3mm, the thickness of the Q235 steel plate is 27mm, the total thickness is 30mm, the length is 50mm, and the width is 25mm. Vacuumize and seal the combined blanks, place them in a heating furnace and heat them to 400°C. 30min, reheat to 550°C, keep warm for 40min, take the billet out of the heating furnace and roll, the reduction of the first pass is 30%, the reduction of the last pass is 2%, and the reductions are 10mm, 4mm, respectively. 3mm, 1mm, the total reduction is 6...

Embodiment 2

[0035] The surface-treated 304 stainless steel sheet blank is coated with an anti-seepage layer. The upper layer is 304 stainless steel sheet, and the lower layer is Q235 carbon steel sheet. They are symmetrically combined. The anti-seepage layer is in the middle of the interface between stainless steel and carbon steel. The thickness of the 304 stainless steel sheet is The thickness of the Q235 steel plate is 27mm, the total thickness is 30mm, the length is 50mm, and the width is 25mm. Vacuumize and seal the combined billets, place them in a heating furnace and heat them to 450°C, keep them warm for 30min, and then Heat to 550°C, hold for 40 minutes, take the billet out of the heating furnace and roll, the first pass reduction is 30%, the last pass reduction is 2%, the reductions are 10mm, 4mm, 3mm, 1mm respectively , the total reduction is 60%.

[0036] The test performance of the stainless steel carbon steel clad plate prepared by warm rolling in this example is as follows:...

Embodiment 3

[0038] The surface-treated 304 stainless steel sheet blank is coated with an anti-seepage layer. The upper layer is 304 stainless steel sheet, and the lower layer is Q235 carbon steel sheet. They are symmetrically combined. The anti-seepage layer is in the middle of the interface between stainless steel and carbon steel. The thickness of the 304 stainless steel sheet is The thickness of the Q235 steel plate is 27mm, the total thickness is 30mm, the length is 50mm, and the width is 25mm. Vacuumize and seal the combined billets, place them in a heating furnace and heat them to 500°C, keep them warm for 30min, and then Heat to 550°C, hold for 40 minutes, take the billet out of the heating furnace and roll, the first pass reduction is 30%, the last pass reduction is 2%, the reductions are 10mm, 4mm, 3mm, 1mm respectively , the total reduction is 60%.

[0039] The test performance of the stainless steel carbon steel clad plate prepared by warm rolling in this example is as follows:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com