Method for activating persulfate with sludge-based biochar and synergistically removing tetracycline in water

A technology for activating persulfate and persulfate, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of reducing tetracycline effluent concentration, secondary pollution of water environment, etc. Optimize the sewage treatment process, realize energy saving and emission reduction, and solve the effect of secondary pollution of water environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of sludge-based biochar:

[0032] The remaining sludge from the municipal sewage treatment plant is directly dried. After drying, the moisture content of the sludge is controlled to <25%. The obtained dried sludge is crushed and passed through a 120-mesh polyethylene sieve. The particle size range is controlled to <20mm, and the treated sludge is put into a muffle furnace for pyrolysis. The temperature in the muffle furnace is controlled at 500°C, and the heating rate is 15°C / min. The sludge reaches the ideal temperature in the carbonization device After staying for 120 minutes, the solid product after pyrolysis is fully cooled and then taken out. The solid product after pyrolysis is washed with dilute hydrochloric acid and deionized water in sequence, and the sludge-based biochar is obtained after drying.

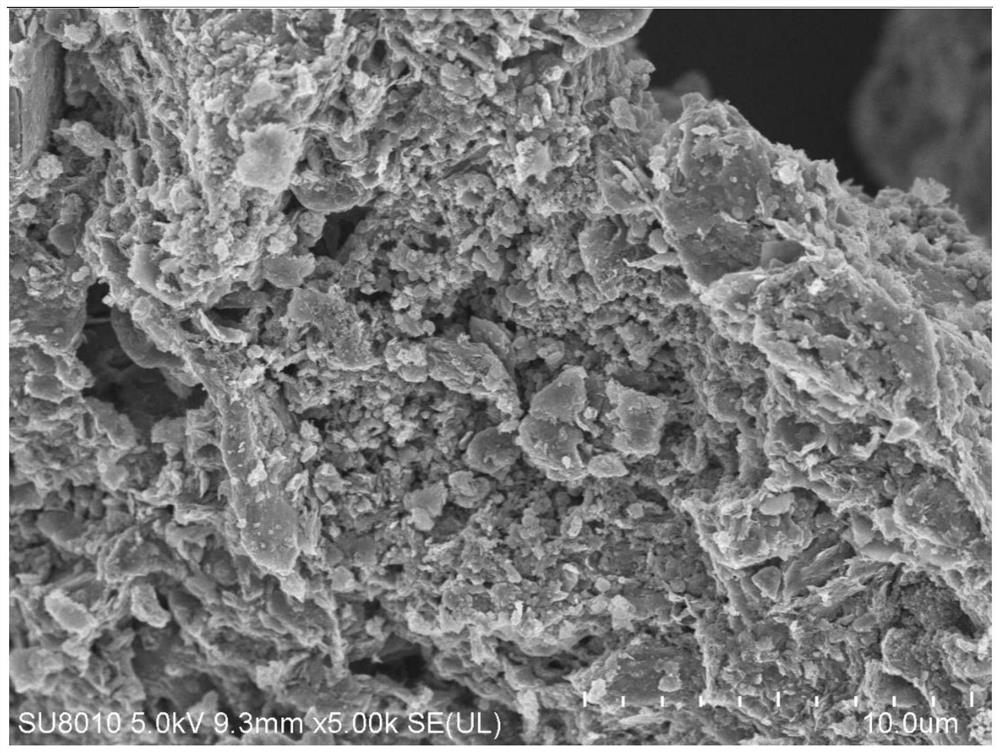

[0033] SEM analysis was carried out on the prepared sludge-based biochar, such as figure 1 As shown, it shows that the biochar cultured from sludge has...

Embodiment 2

[0043] Preparation of sludge-based biochar:

[0044]The remaining sludge from the municipal sewage treatment plant is directly dried. After drying, the moisture content of the sludge is controlled to <25%. The obtained dried sludge is crushed and passed through a 120-mesh polyethylene sieve. The particle size range is controlled to <20mm, and the treated sludge is put into a muffle furnace for pyrolysis. The temperature in the muffle furnace is controlled at 500°C, and the heating rate is 15°C / min. The sludge reaches the ideal temperature in the carbonization device After staying for 120 minutes, the solid product after pyrolysis is fully cooled and then taken out. The solid product after pyrolysis is washed with dilute hydrochloric acid and deionized water in sequence, and the sludge-based biochar is obtained after drying.

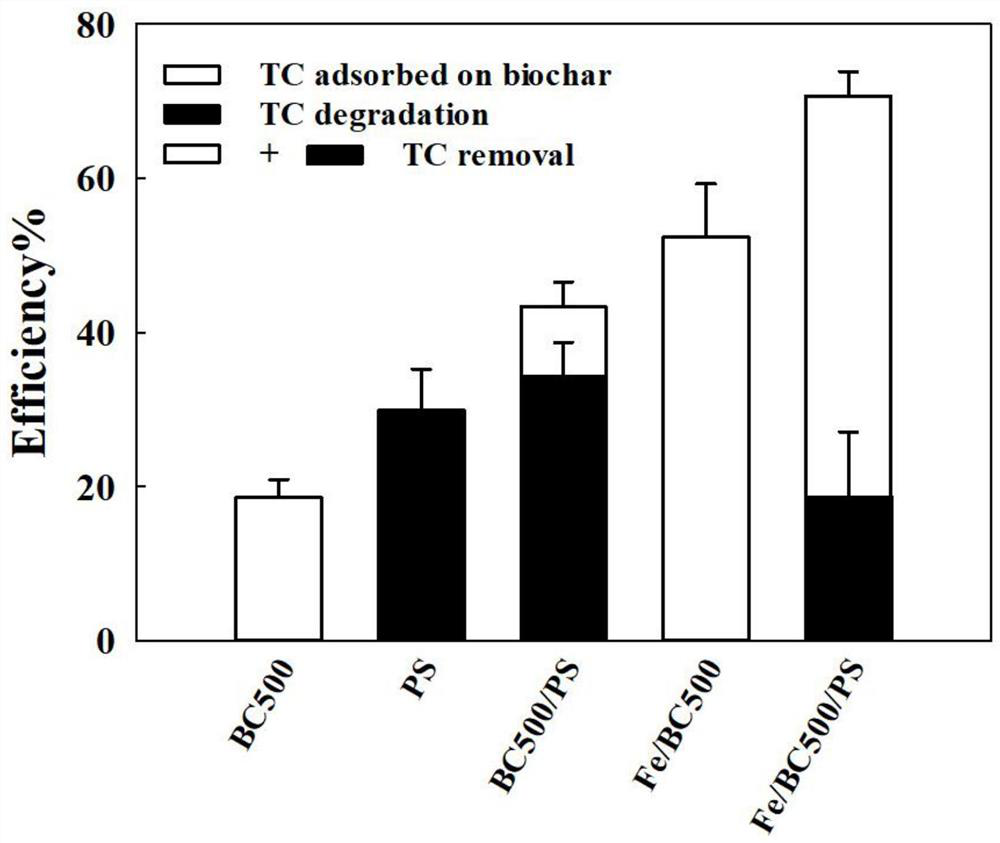

[0045] The two systems for removing tetracycline are: only sludge-based biochar, ferric ion + sludge-based biochar;

[0046] Specifically, ferric ions a...

Embodiment 3

[0052] Preparation of sludge-based biochar:

[0053] The remaining sludge from the municipal sewage treatment plant is directly dried. After drying, the moisture content of the sludge is controlled to <25%. The obtained dried sludge is crushed and passed through a 120-mesh polyethylene sieve. The particle size range is controlled to <20mm, and the treated sludge is put into a muffle furnace for pyrolysis. The temperature in the muffle furnace is controlled at 500°C, and the heating rate is 15°C / min. The sludge reaches the ideal temperature in the carbonization device After staying for 120 minutes, the solid product after pyrolysis is fully cooled and then taken out. The solid product after pyrolysis is washed with dilute hydrochloric acid and deionized water in sequence, and the sludge-based biochar is obtained after drying.

[0054] The two systems for removing tetracyclines are:

[0055] Only sludge-based biochar, ferric ion + sludge-based biochar + persulfate;

[0056] Sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com