Polyvinyl alcohol-pectin embolism microsphere, drug-loaded embolism microsphere and preparation method

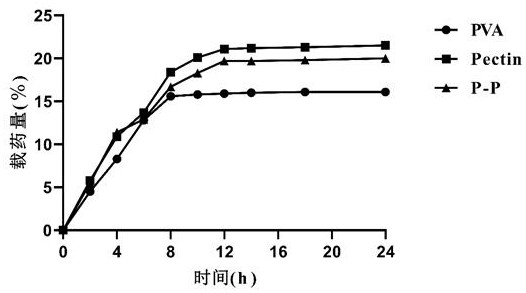

A technology of polyvinyl alcohol and polyvinyl alcohol solution, which is applied in the field of biomedicine and polymer materials, and can solve the problems of low drug loading of polyvinyl alcohol embolization microspheres, non-degradation of polyvinyl alcohol embolization microspheres, and dependence on sustained release of drugs, etc. problem, to achieve good antibacterial coagulation function, high drug loading capacity, and reduce the effect of residual amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

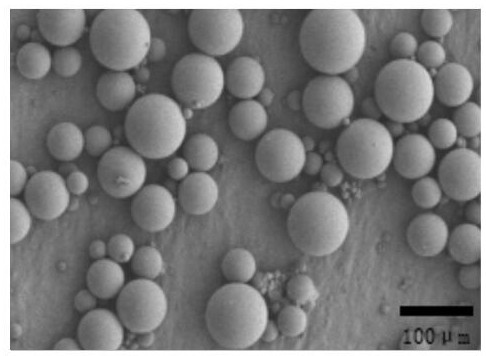

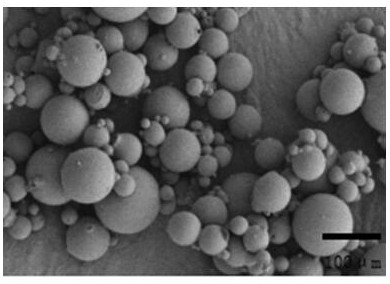

Image

Examples

preparation example Construction

[0035] A preparation method of polyvinyl alcohol-pectin embolization microspheres, comprising the following steps:

[0036] (1) Dissolving polyvinyl alcohol in water to prepare a polyvinyl alcohol solution with a mass concentration of 1-20%; dissolving pectin in water to prepare a pectin solution with a mass concentration of 1-10%; Mix vinyl alcohol solution and pectin solution evenly to obtain polyvinyl alcohol-pectin mixed solution, set aside;

[0037] (2) Dissolve the emulsifier in the continuous phase, mix well to obtain the oil phase, and set aside; the emulsifier is one or both of Span 80 or Tween 80, and the continuous phase is liquid paraffin, petroleum ether and one or both of vegetable oils;

[0038] (3) Add the polyvinyl alcohol-pectin mixed solution obtained in step (1) into the oil phase obtained in step (2), stirring at a speed of 300~5000 r / min, and stir evenly to obtain a polyvinyl alcohol-pectin emulsion ;

[0039] (4) Dissolve the cross-linking agent gluta...

Embodiment 1

[0057] (1) Preparation of polyvinyl alcohol-pectin mixed solution: Take 10 mL of polyvinyl alcohol solution with a mass concentration of 10%, take 10 mL of a pectin solution with a mass concentration of 10%, stir and mix evenly, and the stirring speed is 500 r / min, the stirring time was 8 h, and after standing to remove air bubbles, a polyvinyl alcohol-pectin mixed solution with a certain viscosity was obtained;

[0058] (2) Emulsification and crosslinking: Dissolve 0.5 mL of emulsifier Span-80 in 50 mL of continuous phase liquid paraffin and stir evenly to obtain an oil phase. The rotation speed is 1000 r / min, and the stirring time is 20 min; The polyvinyl alcohol-pectin mixed solution was added dropwise to the oil phase, the stirring speed was 1000 r / min, and the stirring time was 30 min to disperse it evenly to obtain a polyvinyl alcohol-pectin emulsion. Dissolve 2 mL of glutaraldehyde and 1 mL of hydrochloric acid in 5 mL of ether to obtain a cross-linking agent solution,...

Embodiment 2

[0068] (1) Preparation of polyvinyl alcohol-pectin mixed solution: take 5 mL of polyvinyl alcohol solution with a mass concentration of 12%, and 15 mL of a pectin solution with a mass concentration of 10%, stir and mix evenly at a stirring rate of 800 r / min, the stirring time was 8 h, and after standing to remove air bubbles, a polyvinyl alcohol-pectin mixed solution with a certain viscosity was obtained;

[0069] (2) Emulsification and crosslinking: Dissolve 0.5 mL of emulsifier Span-80 in 80 mL of liquid paraffin and stir evenly to obtain an oil phase. The rotation speed is 800 r / min, and the stirring time is 30 min; The vinyl alcohol-pectin mixed solution was added dropwise to the oil phase, the stirring speed was 1500 r / min, and the stirring time was 30 min, so that it could be dispersed evenly, and the polyvinyl alcohol-pectin emulsion was obtained. Dissolve 2.4 mL of glutaraldehyde and 1.2 mL of hydrochloric acid in 6 mL of ether to obtain a cross-linking agent solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com