High-strength galvanized steel sheet, high-strength parts and their manufacturing method

A technology of galvanized steel sheet and manufacturing method, which is applied in the direction of manufacturing tools, hot-dip coating process, furnace, etc., can solve the problems of easy formation of micropores and deterioration of bendability, etc., and achieve the improvement of collision safety, plating and bendability excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

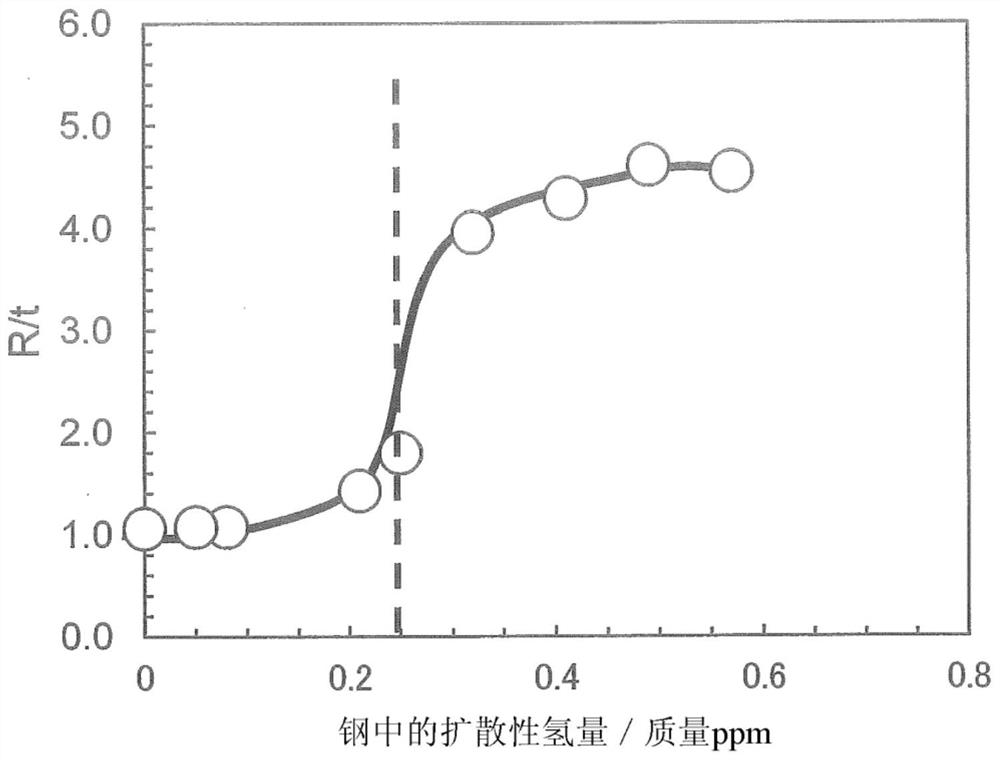

[0146] In order to confirm the influence of the amount of hydrogen in steel, the study shown in Example 1 was carried out.

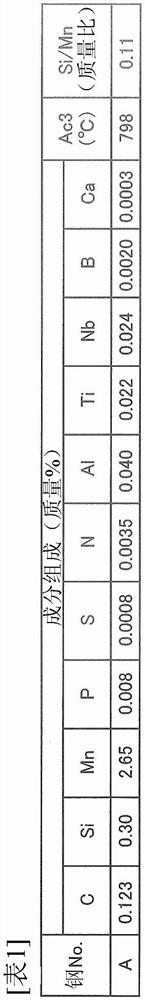

[0147] Molten steel with the composition shown in Table 1 was smelted in a converter to produce slabs with an average flow rate of molten steel at the solidification interface near the meniscus of the mold at 18 cm / sec and an average casting speed of 1.8 m / min. This slab was heated to 1200°C, and a hot-rolled coil was produced at a finishing temperature of 840°C and a coiling temperature of 550°C. The hot-rolled steel sheets obtained from the hot-rolled coils were pickled, and then cold-rolled steel sheets with a thickness of 1.4 mm were produced at a cold reduction ratio of 50%. The cold-rolled steel sheet was annealed in an annealing furnace atmosphere with various hydrogen concentrations and a dew point of -30°C, and heated to an annealing temperature of 790°C (within the range of Ac3 point + 20°C or lower), so as to increase the temperature from the ...

Embodiment 2

[0156] In Example 2, the following galvanized steel sheets were manufactured and evaluated.

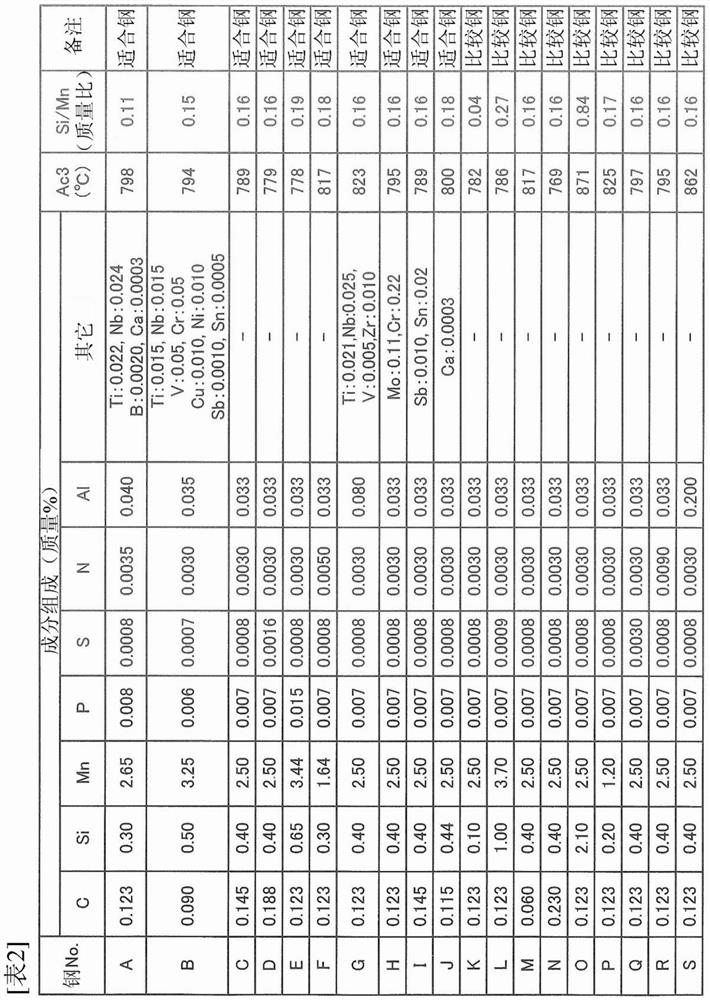

[0157] Melt molten steel with the composition shown in Table 2 using a converter, reheat the slab cast under the conditions shown in Table 3 to 1200°C, and perform hot rolling at a finish rolling temperature of 800 to 830°C to make the coil The temperature at the time of coiling was 560 degreeC, and the hot rolled coil was manufactured. The hot-rolled steel sheet obtained from the hot-rolled coil was pickled, and the steel sheet was subjected to the processes of cold rolling, annealing, coating treatment, width trimming, and post-treatment under the conditions shown in Table 3 to produce a 1.4 mm thick galvanized steel sheet. steel plate. It should be noted that immediately after the plating treatment (galvanizing treatment), the alloying treatment of galvanizing was performed under the conditions of 500° C. for 20 seconds. In addition, the steps of width trimming and post-processin...

Embodiment 3

[0185] The galvanized steel sheet of the production condition No. 1 (example of the present invention) in Table 3 of Example 2 was press-formed to manufacture the parts of the example of the present invention. In addition, the galvanized steel sheet of the manufacturing condition No.1 (example of the present invention) in Table 3 of Example 2 and the galvanized steel sheet of the manufacturing condition No. 2 (example of the present invention) of Table 3 of Example 2 were carried out by spot welding Joining, the parts of the example of this invention were manufactured. It was confirmed that the components of these examples of the present invention are excellent in bendability and plating property, and thus can be applied to automobile parts and the like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com